Working solution tank of ultrafine electrical discharge machine

A working liquid tank and electric discharge machining technology, applied in the field of mechanical processing, can solve the problems of working oil circulation, overflow or poor oil speed adjustment, inconvenient processing operations, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

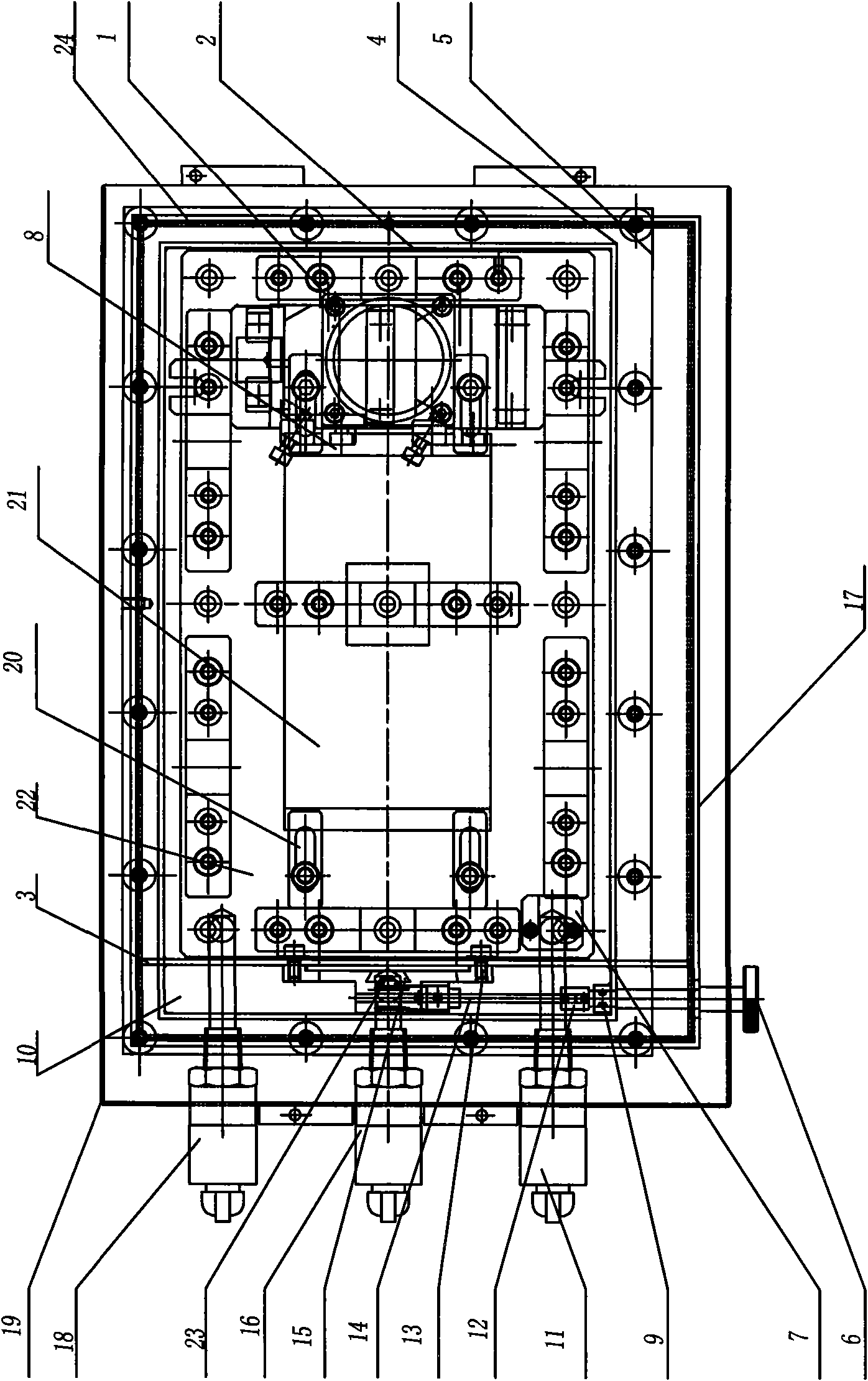

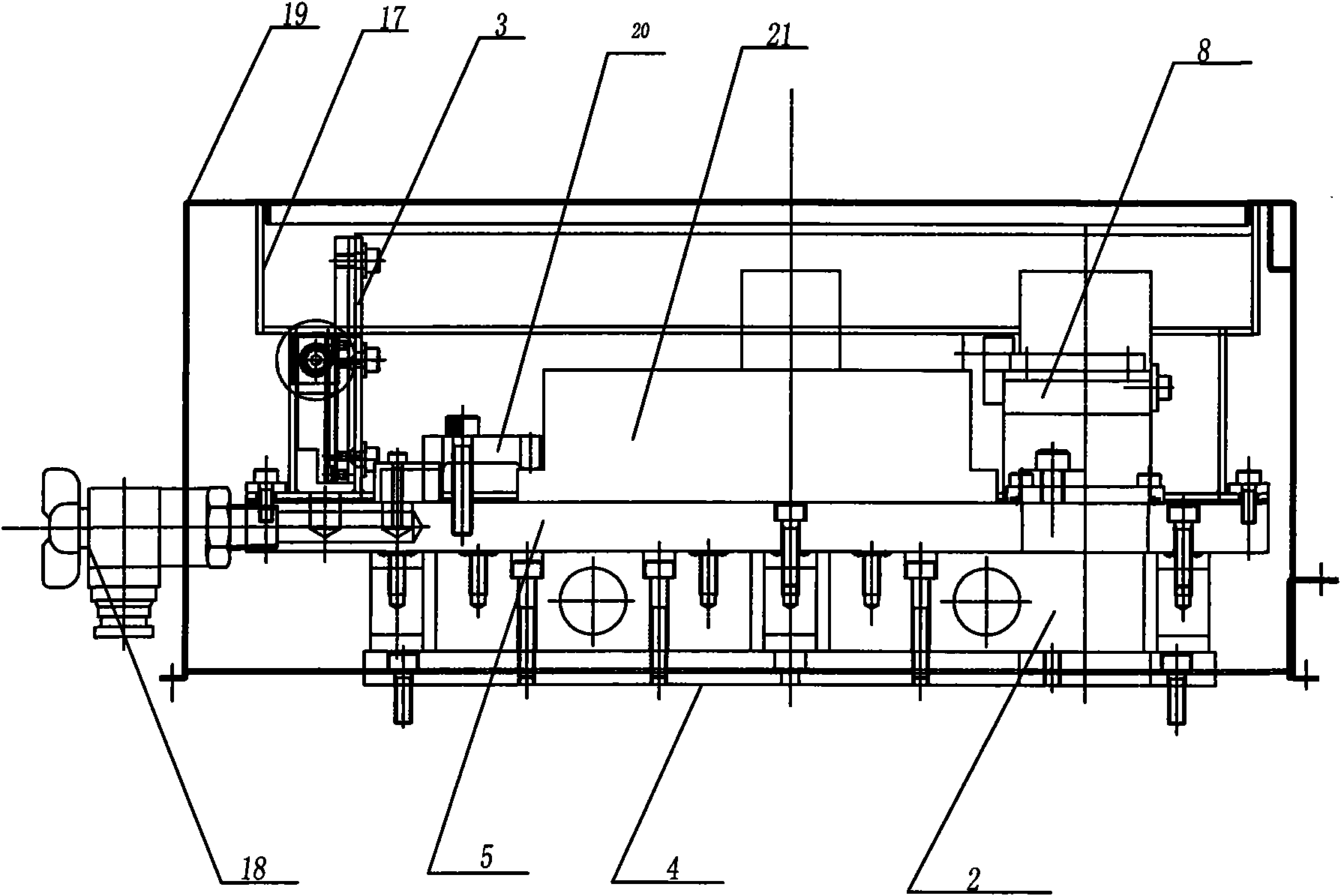

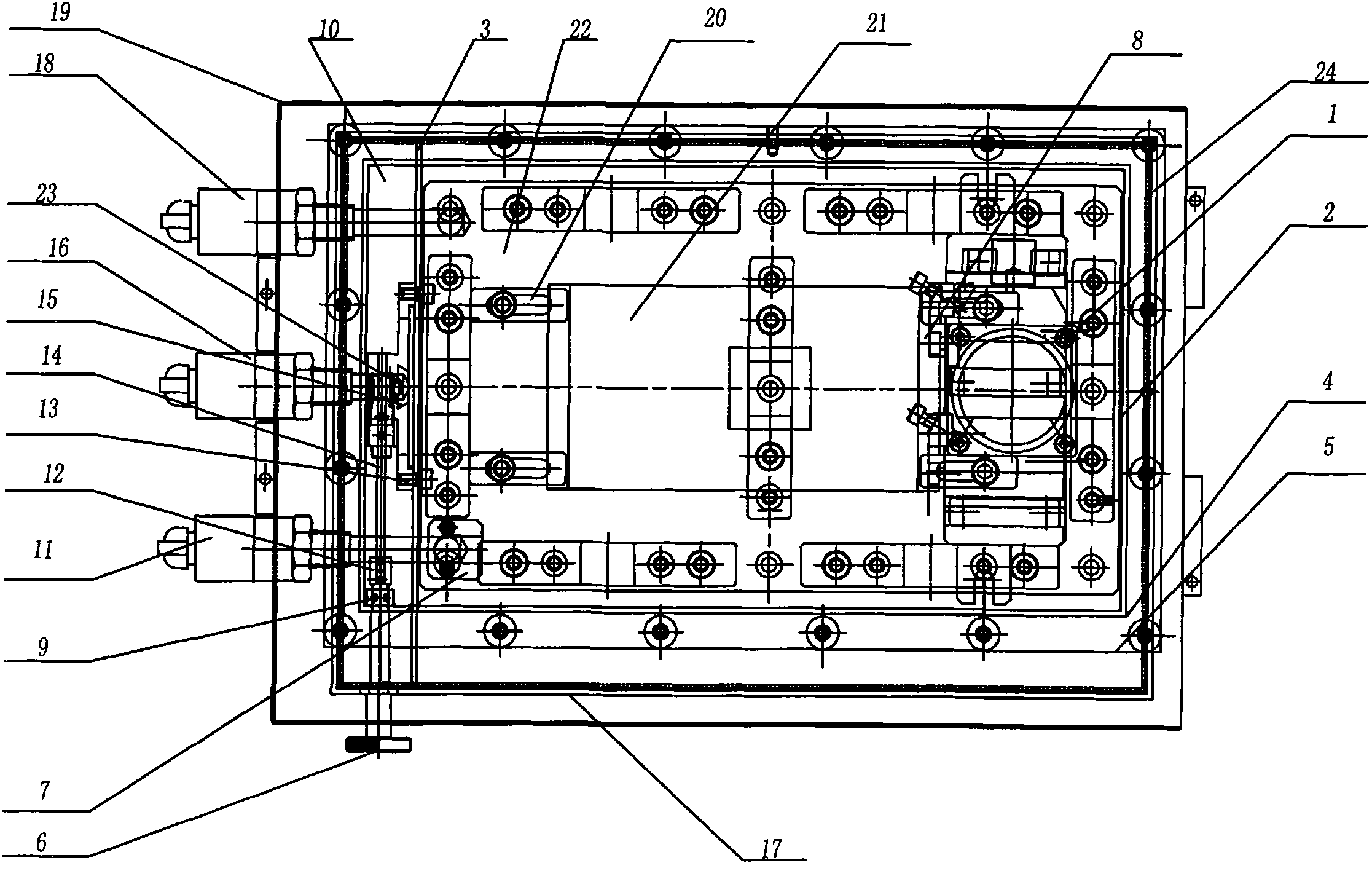

[0009] As shown in the figure: the present invention includes an oil outlet 1, a middle plate 2, a middle baffle 3, a lower bottom plate 4, an upper bottom plate 5, an adjustment handle 6, an oil inlet 7, an anti-copy block 8, a sealing ring 9, an overflow Area 10, oil inlet valve 11, coupling 12, fastening bolt 13, transmission shaft 14, screw rod 15, overflow valve 16, side plate 17, oil return valve 18, housing 19, fixture positioning block 20, Workpiece fixture 21 , processing area 22 , cover plate 23 and end side plate 24 .

[0010] Such as figure 1 and figure 2 As shown: the bottom of the housing 19 is provided with an upper base plate 5, and a lower base plate 4 is arranged below the upper base plate 5; an intermediate plate 2 is provided between the upper base plate 5 and the lower base plate 4, and the intermediate plate 2 is used for Adjust the height between the lower base plate 4 and the upper base plate 5. When in use, the lower base plate 4 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com