Non-capsule two-stage tyre setting drum

A two-stage, shaping drum technology, which is applied in the field of tire building machinery, can solve the problems of easily damaged sealed capsules, increase manufacturing and use costs, and affect the accuracy and quality of tire building processing, so as to improve accuracy and quality and save money. Manufacturing and usage costs, and the effect of high embryonic precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

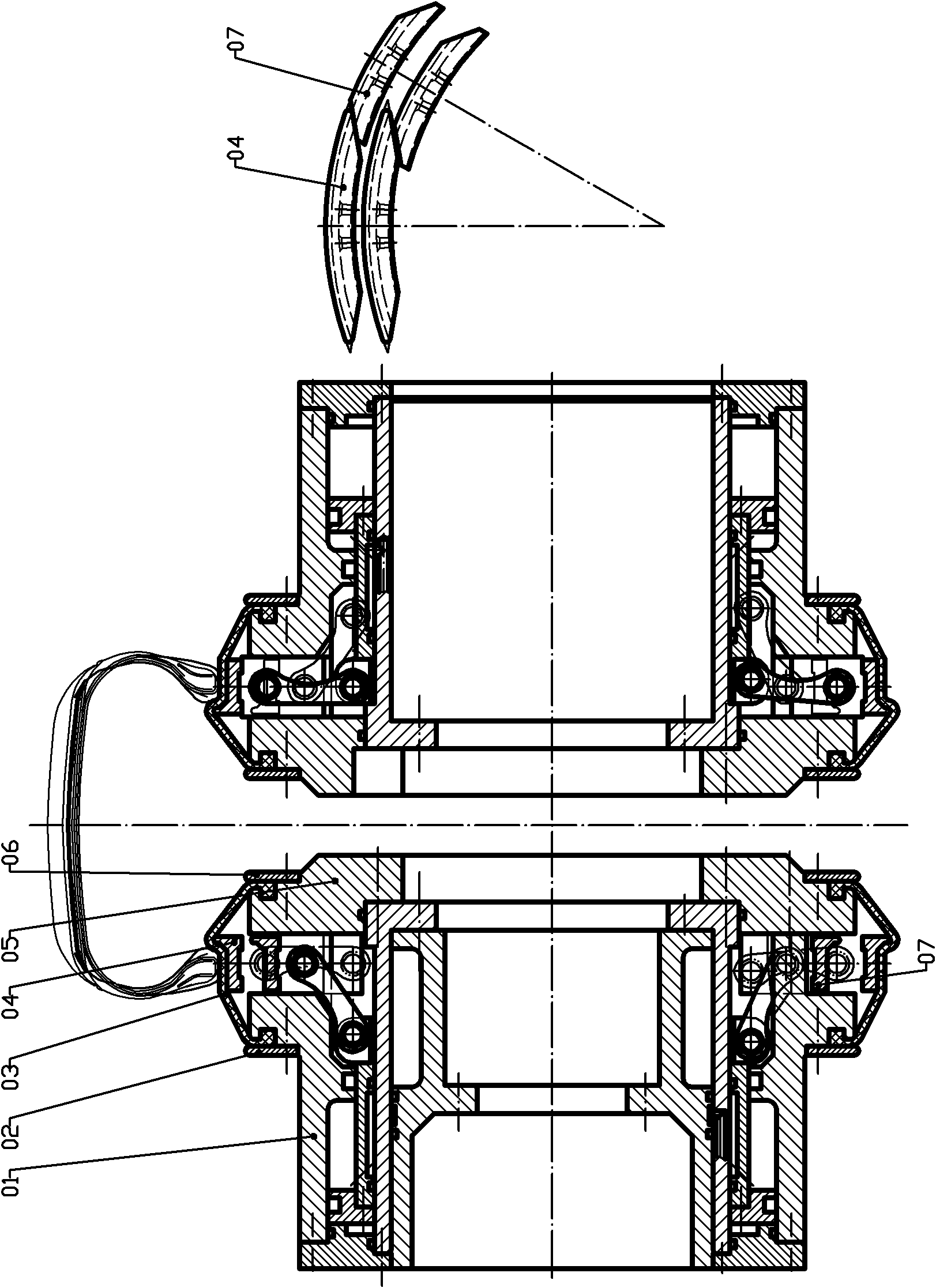

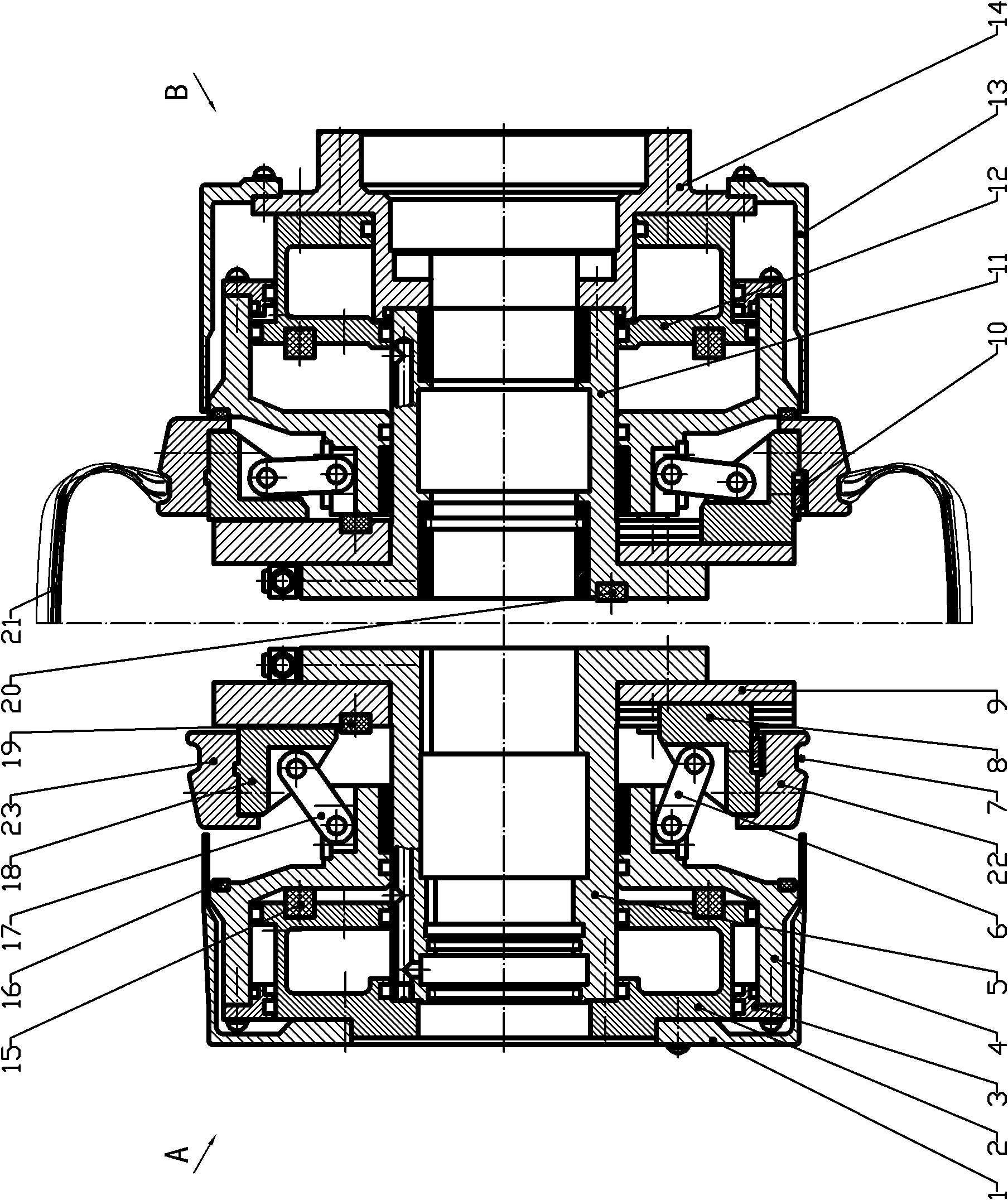

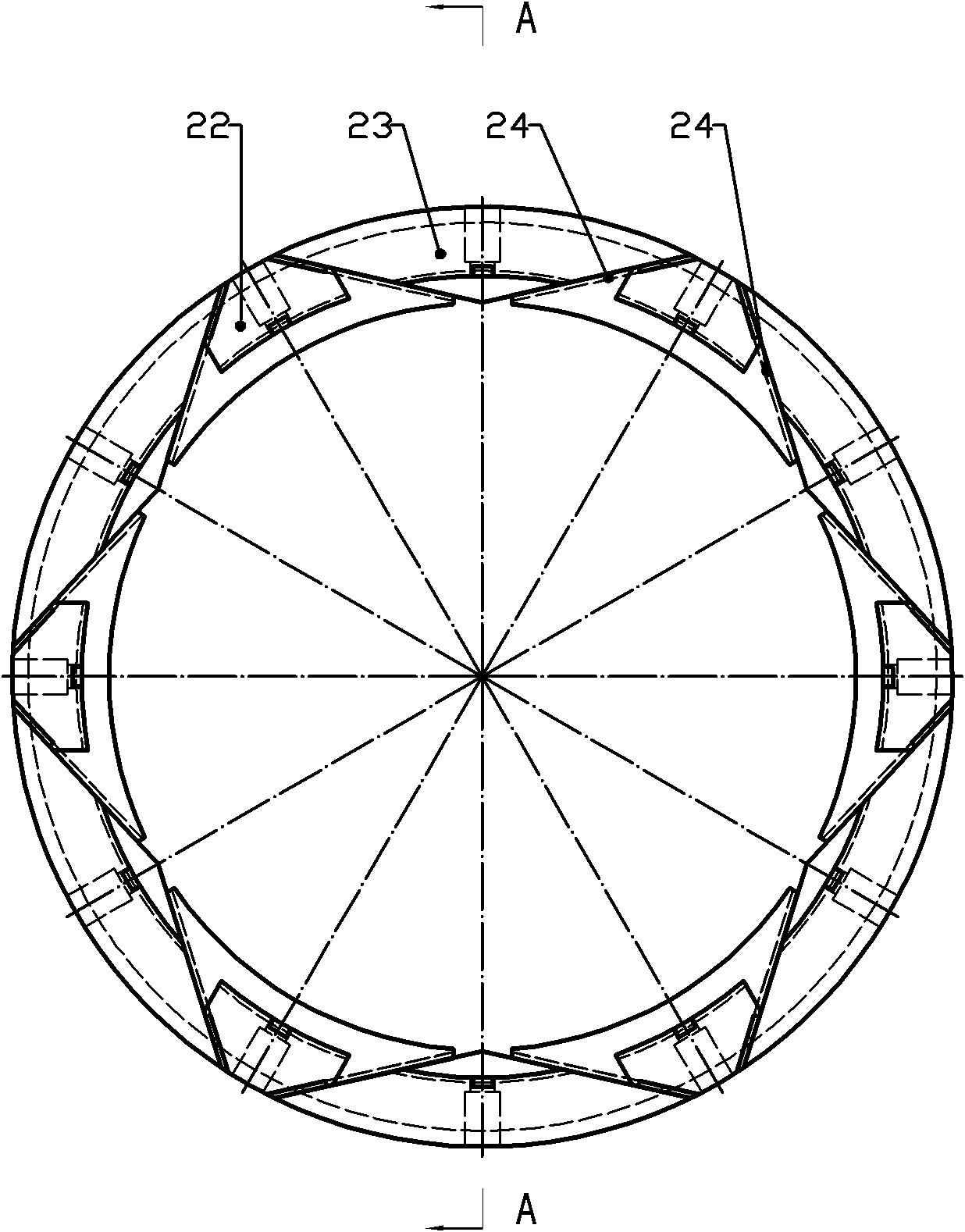

[0010] refer to Figure 2-Figure 6 , a capsule-free two-stage tire shaping drum, consisting of a left drum A and a right drum B, the left drum and the right drum are equipped with a cylinder power unit and a contraction ring, and the cylinder power unit includes a cylinder body and a cylinder head 3 and movable ring 4, the left cylinder block 2 of the cylinder power device of the left drum A is fixedly connected with the left bushing 5; the right cylinder body 12 of the cylinder power device of the right drum B is fixedly connected on the right flange 14, and the right The flange 14 is fixedly connected with the right shaft sleeve 11, and the left contraction ring on the left drum A and the right contraction ring on the right drum B are arranged symmetrically. On the outer periphery of the contraction ring, there is a bead 21 clamp toe 7. The toe opening 7 of the bead clamp is an annular groove; the contraction ring is composed of 6 large sector blocks 23 and 6 small sector bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com