Placing device for high-pressure gun in ore pulp pipe delivery

A medium-high pressure and slurry technology, which is applied in the pipeline system, liquid cleaning methods, chemical instruments and methods, etc. It can solve the problems of difficult placement of high-pressure water guns and difficult spray angles of water gun heads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

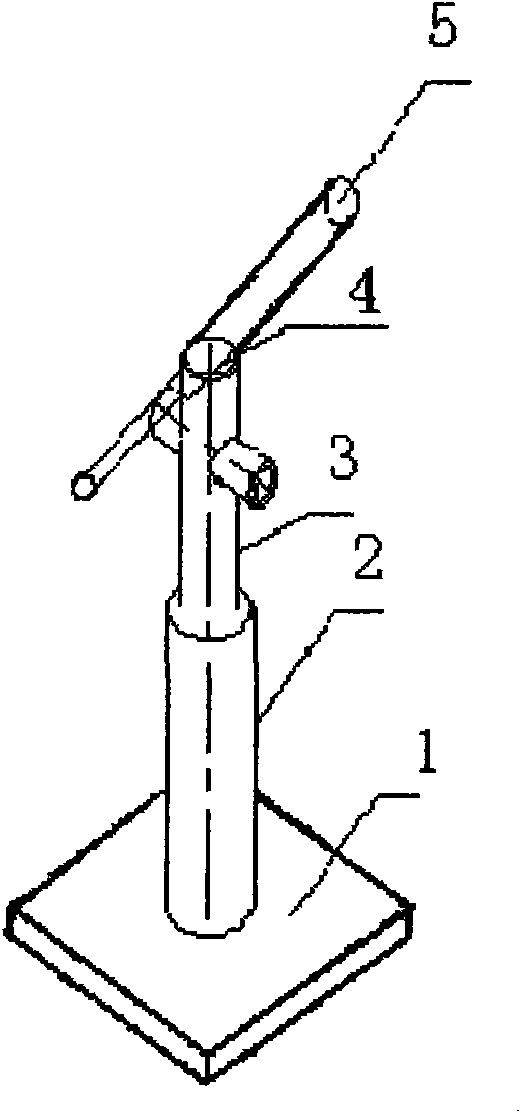

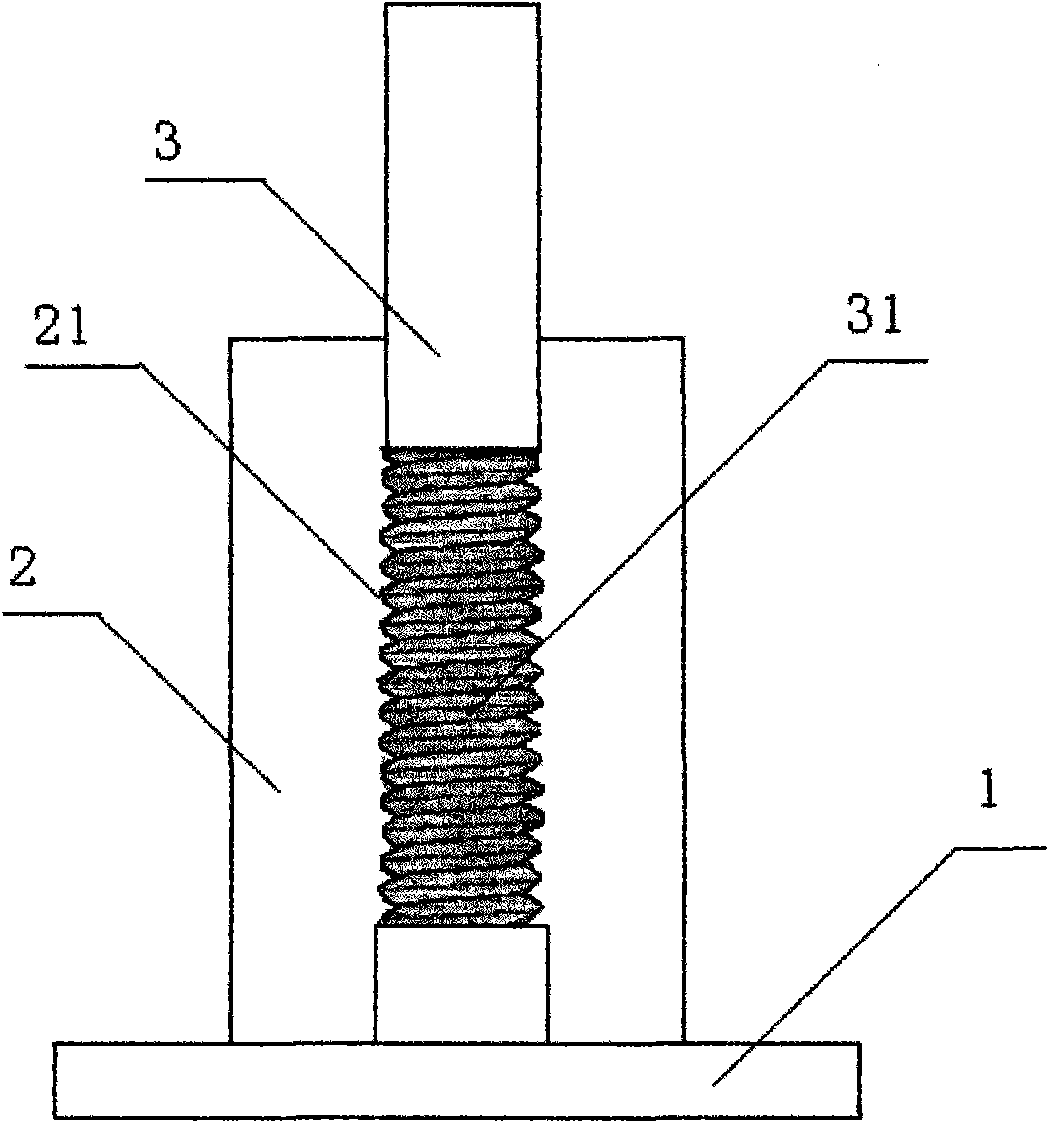

[0013] Combine below figure 1 and figure 2 , the present invention is further described:

[0014] Such as figure 1 As shown, a device for placing a high-pressure water gun in a slurry pipeline transportation includes a vertical tubular support 2 and a screw 3, a high-pressure water gun head 5 is fixedly arranged on the screw 3, and the vertical tubular support 2 is arranged at the point where the slurry flows into On the working platform of the pulping tank; it also includes a mounting base 1, the vertical tubular support 2 is installed on the mounting base 1, and the mounting base 1 is fixed on the working platform of the pulping tank. A high-pressure flushing water gun head fixing point 4 specially used for installing a high-pressure water gun head 5 is provided on the top of the vertical tubular support 2 .

[0015] Such as figure 2 As shown, the inner tube wall of the vertical tubular support 2 is provided with an internal thread 21, and the outer surface of the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com