Infrared analysis aerosol sample cell

An infrared analysis and sample cell technology, which is applied in the field of instrument analysis and optical detection, can solve the problems of small amount of analyzable samples, inability to meet the needs of infrared detection, and high cost, achieve low processing costs, and solve the problems of infrared spectroscopy analysis. , the effect of large effective volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

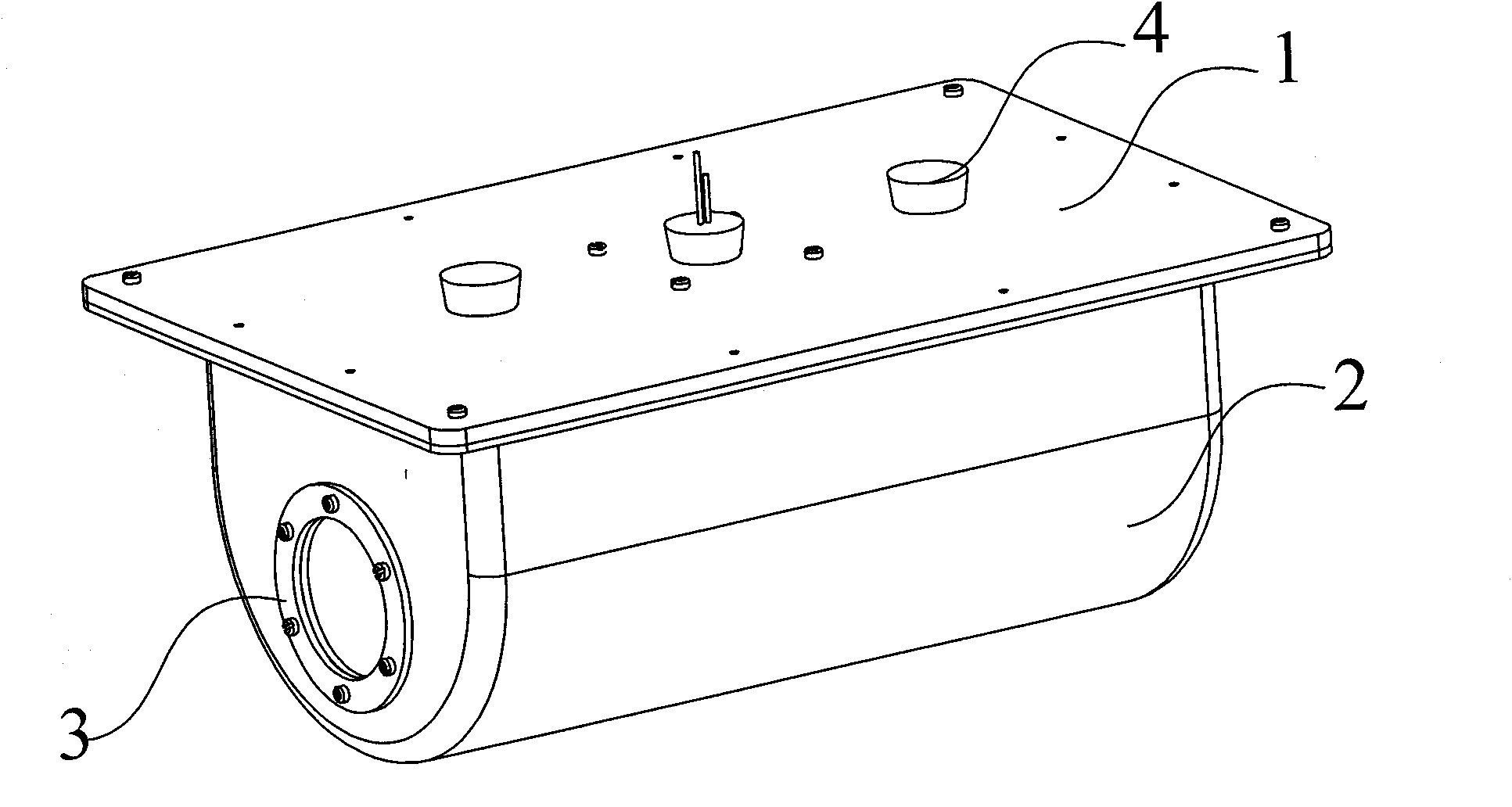

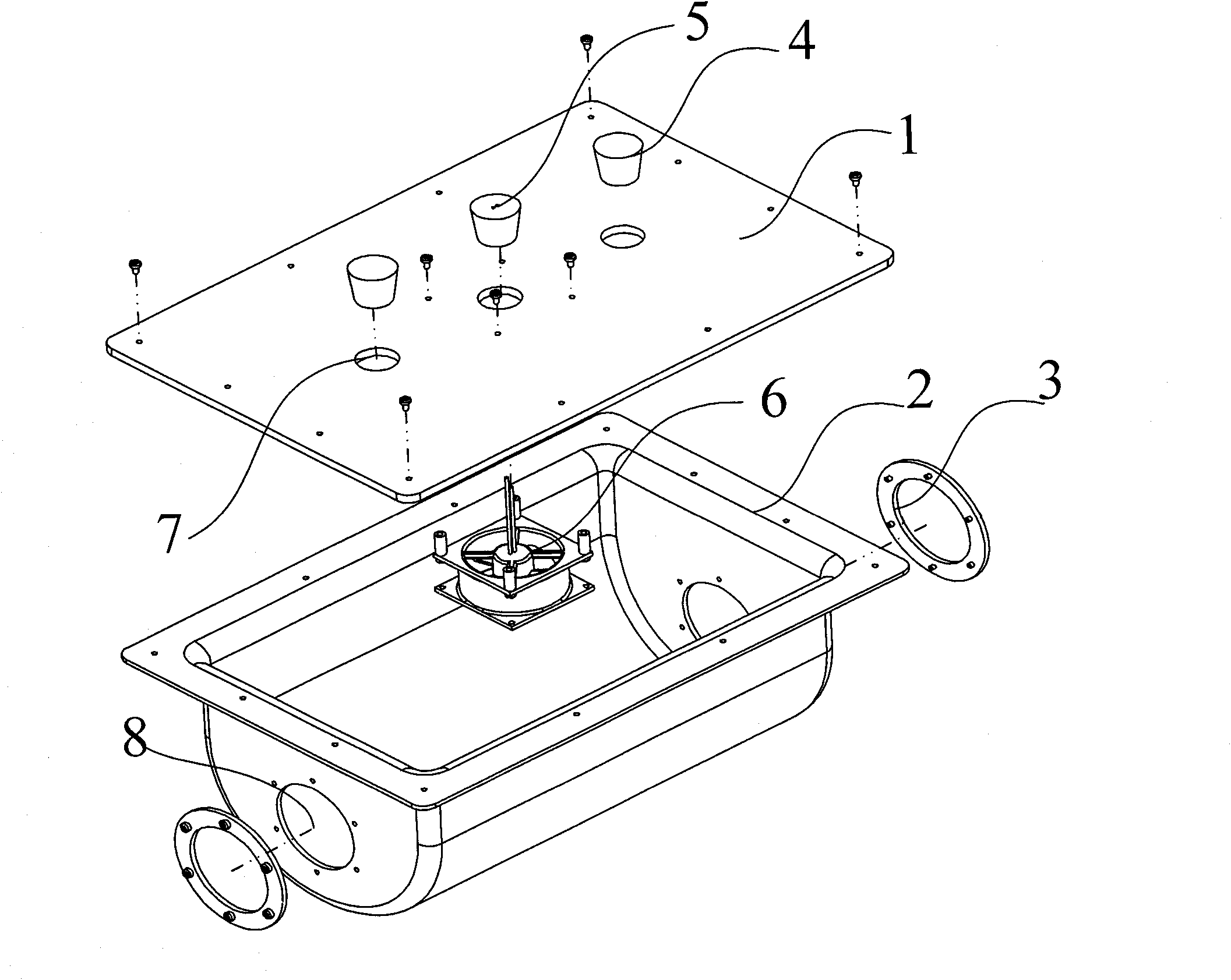

[0027] Such as figure 1 , 2 As shown, an aerosol sample cell for infrared analysis specifically includes:

[0028] A sample chamber 2 adopts a U-shaped groove structure, and the top edge is turned outward and is provided with several screw holes; the two ends of the sample chamber are flat plates with a round hole 8 in the center, and screw holes are arranged around the round hole 8;

[0029] A top cover 1, which can be processed from thicker plexiglass, is connected to the top edge of the sample chamber 2 through a threaded hole located on the periphery, and a flexible sealing gasket is arranged at the joint between the two; There are three through holes 7 in the spacing processing; the middle through hole is used to lead out the fan wire, and the through holes on both sides are used to add samples;

[0030] Three sealing plugs 4 are in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com