Molecular flow sampling system and control method for calibrating positive pressure leak based on comparison method

A positive pressure leak, comparison method, applied in the direction of detecting the occurrence of fluid at the leak point, testing fluid tightness, testing machine/structural components, etc., can solve the problem of positive pressure leak calibration that cannot meet the micro leak rate. Problems such as demand, low concentration of leaking gas, and the inability of the positive pressure leak calibration system to extend the lower calibration limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

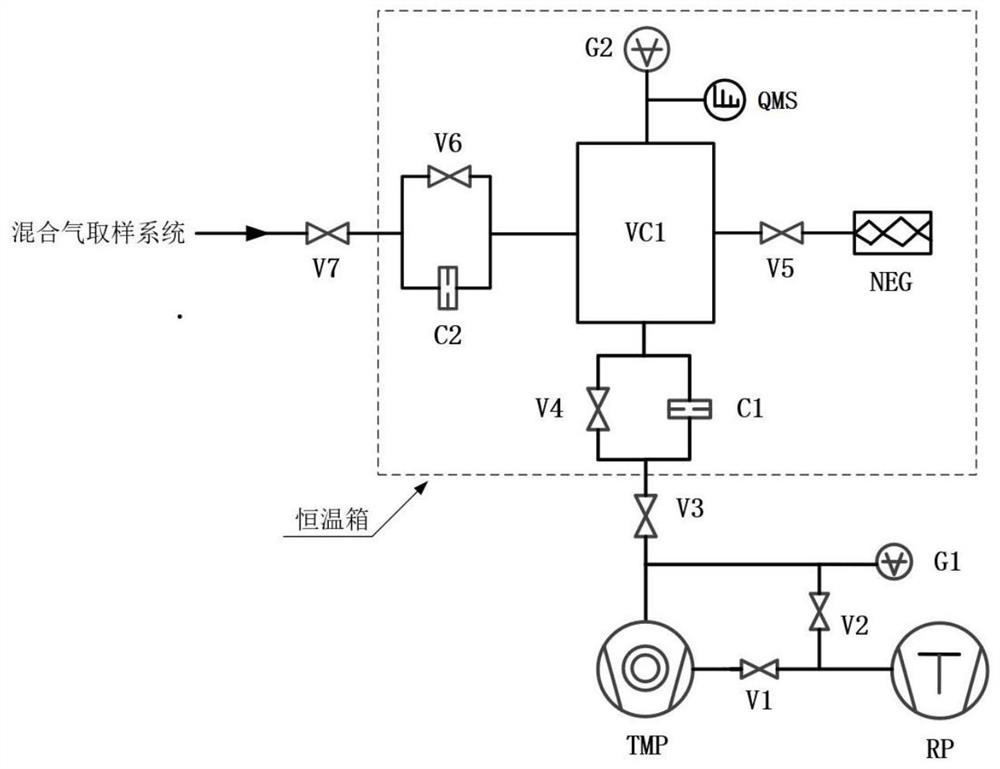

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] The present invention designs a molecular flow sampling system based on the comparison method to calibrate the positive pressure leak, such as figure 1As shown, including mechanical pump RP, molecular pump TMP, first vacuum valve V1, second vacuum valve V2, third vacuum valve V3, fourth vacuum valve V4, fifth vacuum valve V5, sixth vacuum valve V6, seventh vacuum valve Vacuum valve V7, mass spectrometry device VC1, first vacuum gauge G1, second vacuum gauge G2, getter pump NEG, first molecular flow sampling component C1, second molecular flow sampling component C2, quadrupole mass spectrometer QMS and incubator.

[0024] Among them, the first vacuum gauge G1 is a resistance vacuum gauge with a full scale of 1000 Torr, and the second vacuum gauge G2 is an ultra-high vacuum separation gauge that meets the standard;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com