Method for reducing abrasion between punch and die sprue bush

A sprue sleeve and mold technology, applied in the field of reducing the wear of punches and mold sprue sleeves, can solve the problems of circulating cooling water stagnant water, wear of mold sprue sleeves and punches, poor cooling effect of punches, etc., to achieve The effect of improving the economic efficiency of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific examples.

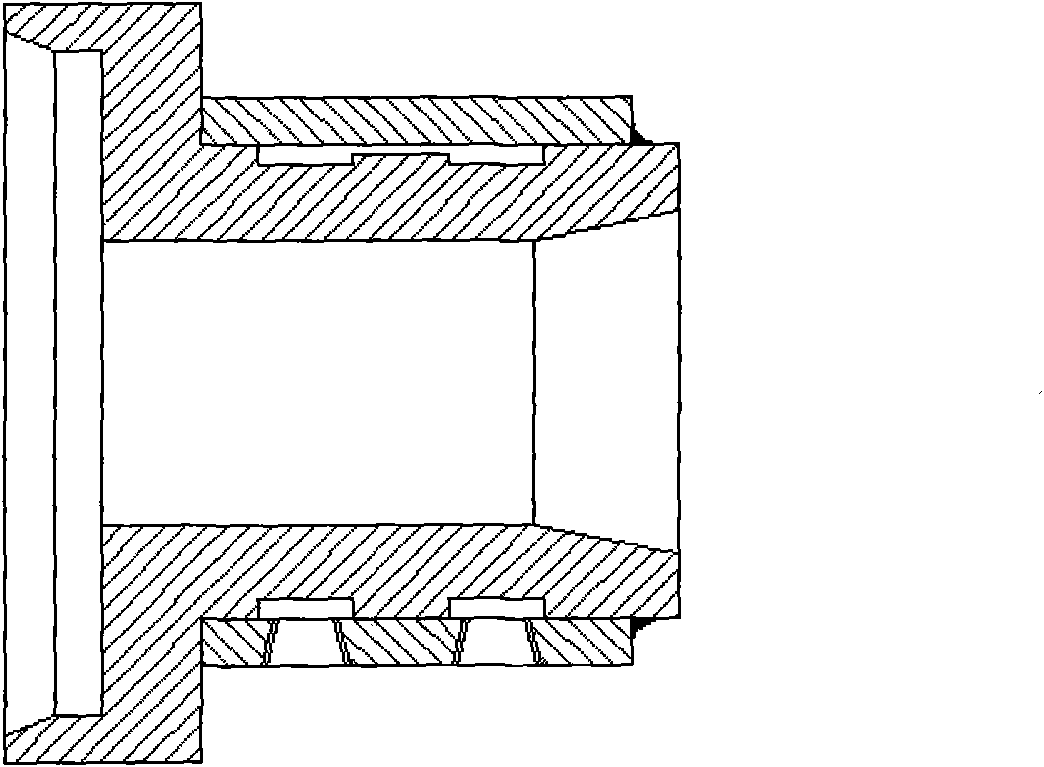

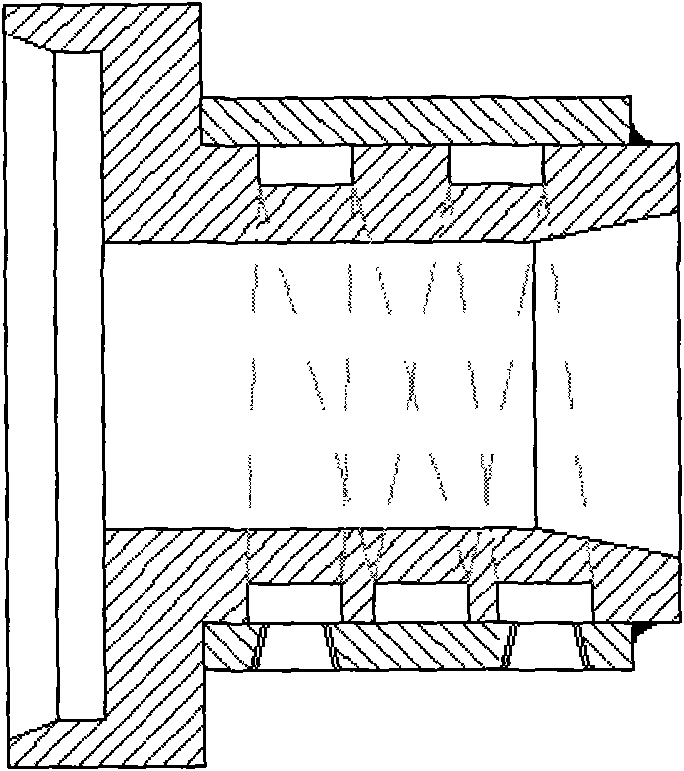

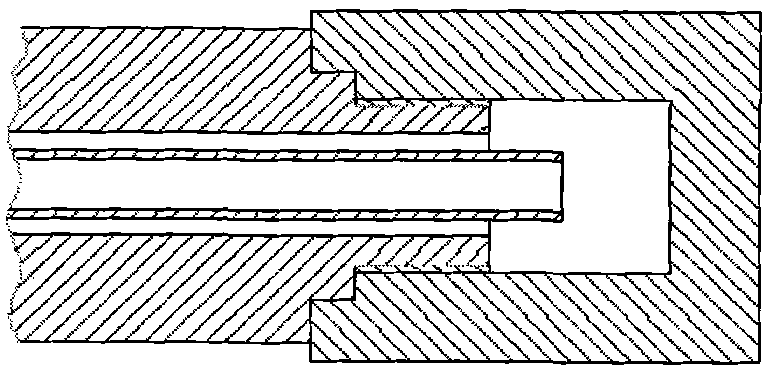

[0018] Such as Figure 1~4 Shown, a kind of method that the present invention reduces punch and mold sprue bushing wear and tear, comprises:

[0019] (1) Change the mold gate sleeve from the circular design of the original cooling channel to the spiral design, and increase the width and depth of the cooling channel at the same time;

[0020] (2) The length of the water inlet copper pipe of the shooting rod and the bottom of the inner hole of the punch are kept at a distance of 5 mm to remove stagnant water;

[0021] After the improvement of the above two points, the cooling effect of the mold sprue sleeve and the punch can be guaranteed, and the fit gap between them can be effectively controlled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com