Explosion-proof type manual fire alarm button

A fire alarm and explosion-proof technology, applied in the direction of alarms, instruments, static electricity, etc., can solve the problem that the plastic shell cannot effectively reduce the volume resistivity, and achieve the effect of simple and practical overall structure and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The shells of existing explosion-proof manual fire alarm buttons often use plastic as the shell, and antistatic agents are sometimes added to plastics in order to reduce the volume resistivity. However, these measures have not fundamentally reduced the existing explosion-proof manual fire alarm buttons. volume resistivity. The explosion-proof manual fire alarm button of the present invention adopts an iron shell, and the overall structure of the iron shell is simple and practical, and can effectively realize the grounding, so that the volume resistivity of the explosion-proof manual fire alarm button is always kept at a low level, and even used The volume resistivity is 0.

[0027] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

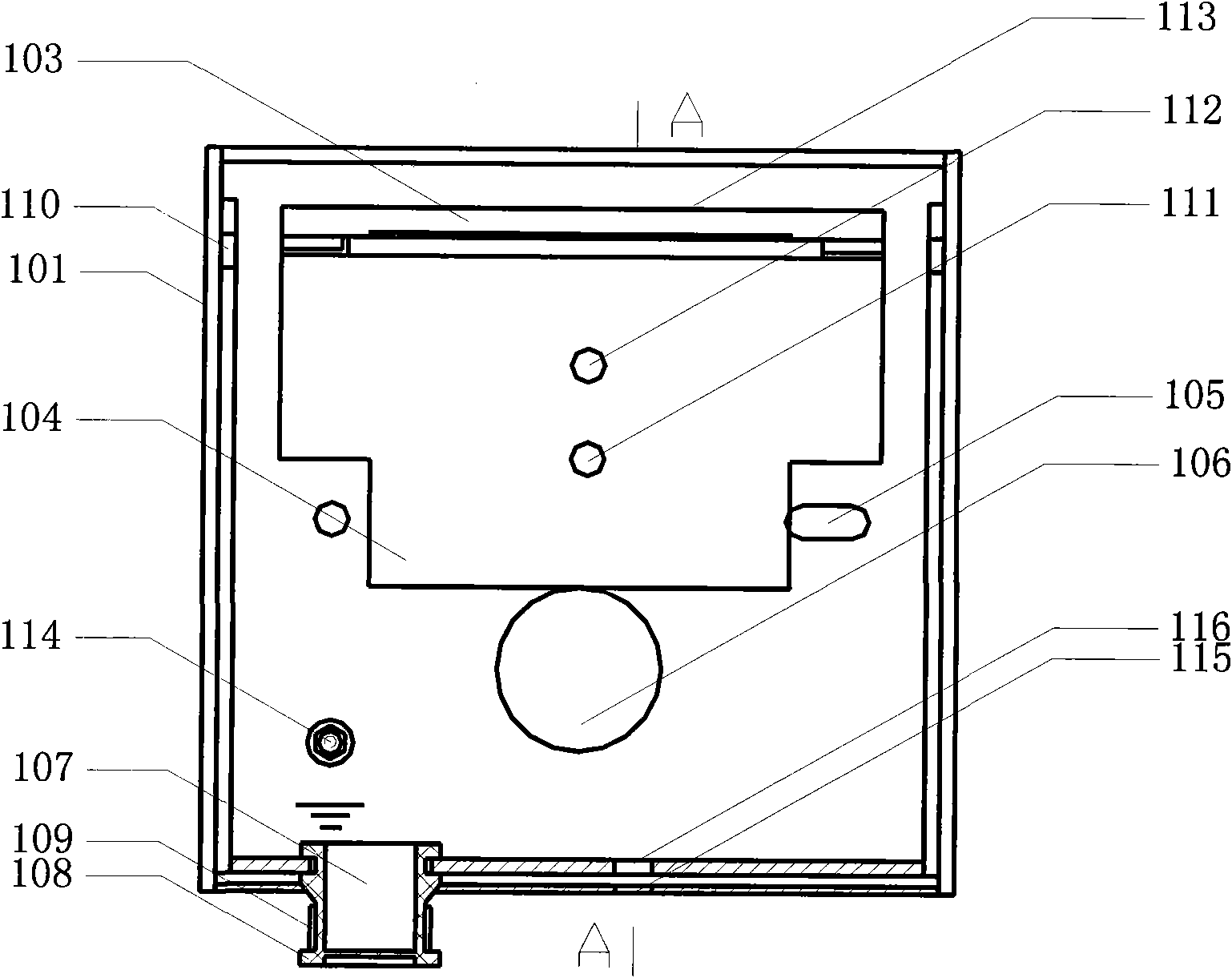

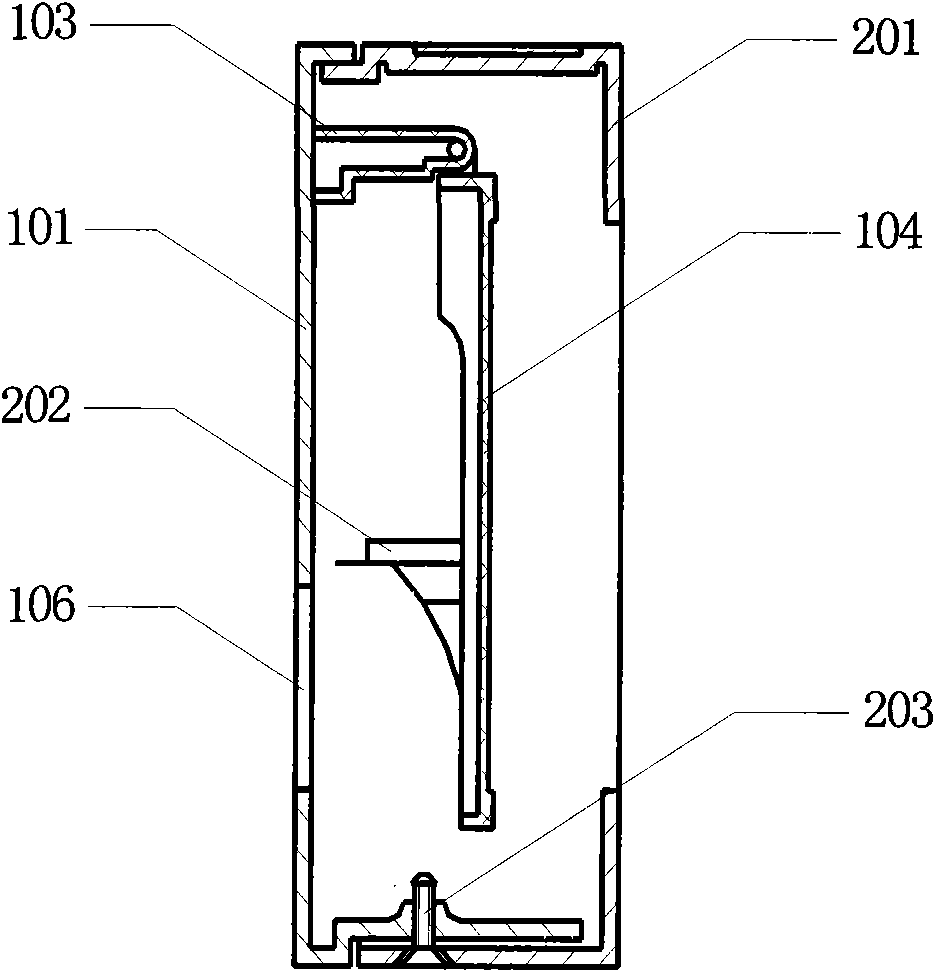

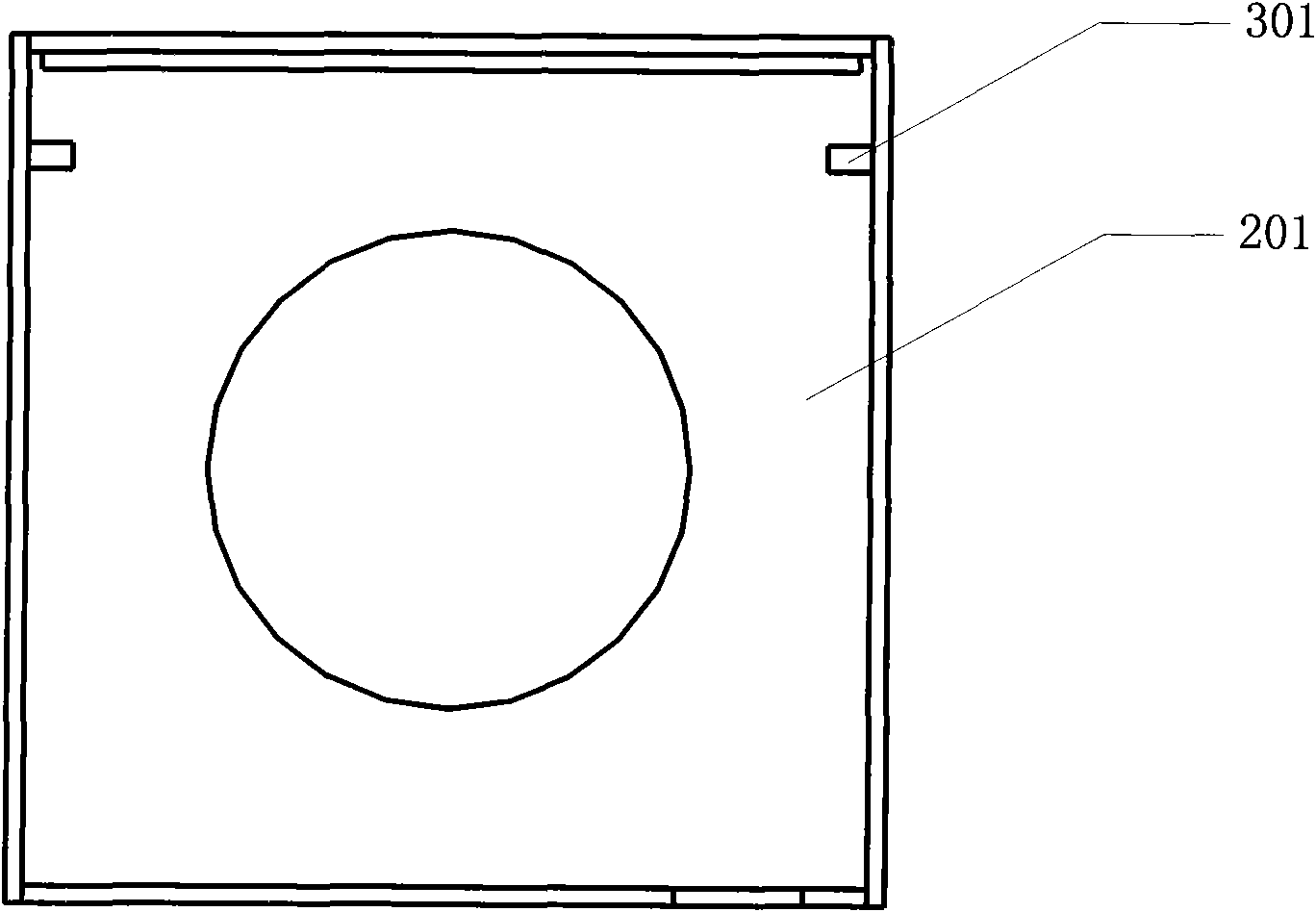

[0028] Such as figure 1 Shown is a schematic view of the internal structure of the bottom shell of the explosion-proof manual fire alar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap