Glass substrate inspecting apparatus and glass substrate inspecting method

A technology for glass substrates and inspection devices, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of unsatisfactory, impractical, complex and large-scale devices, etc., and achieve the effect of correcting bending and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

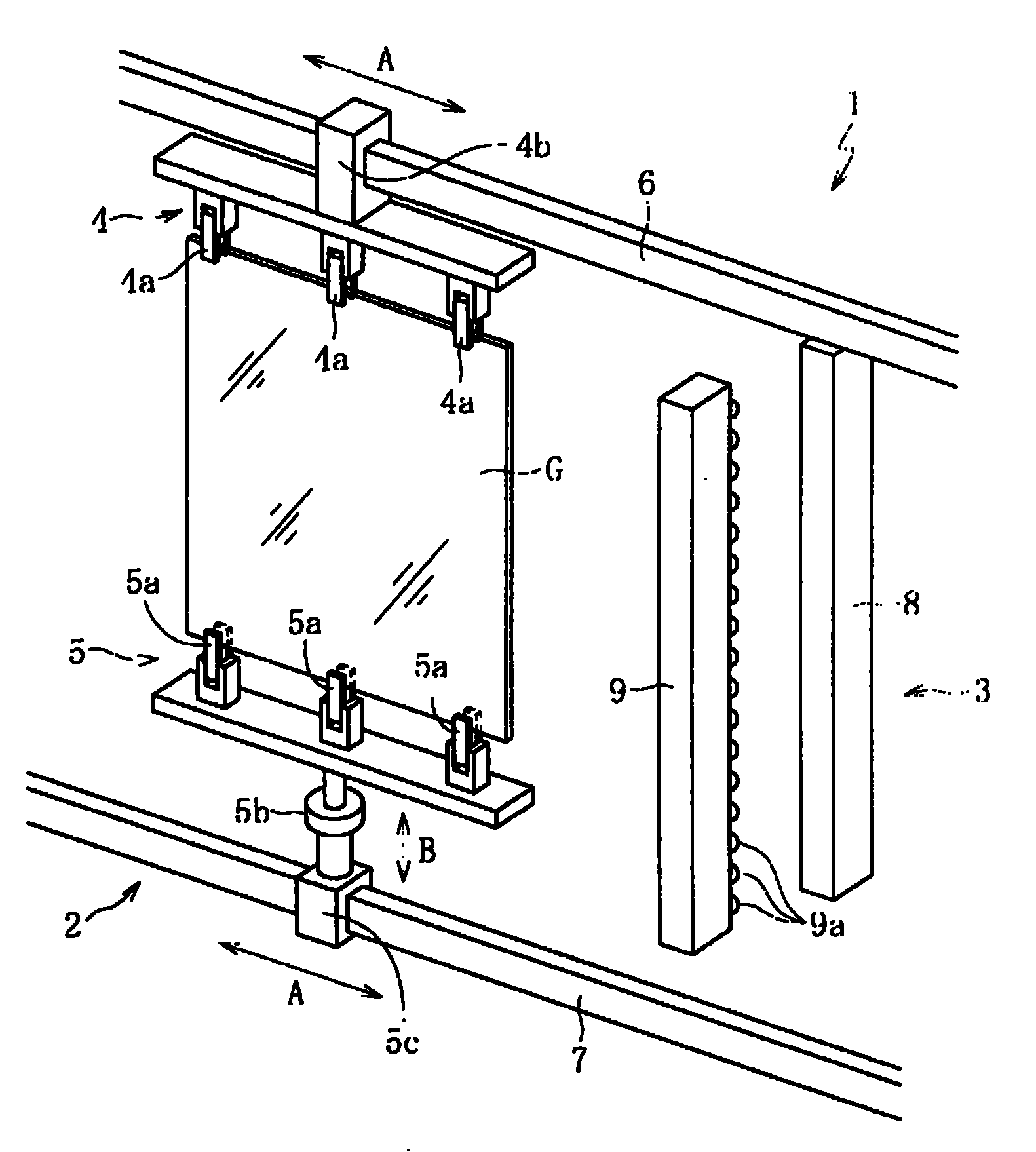

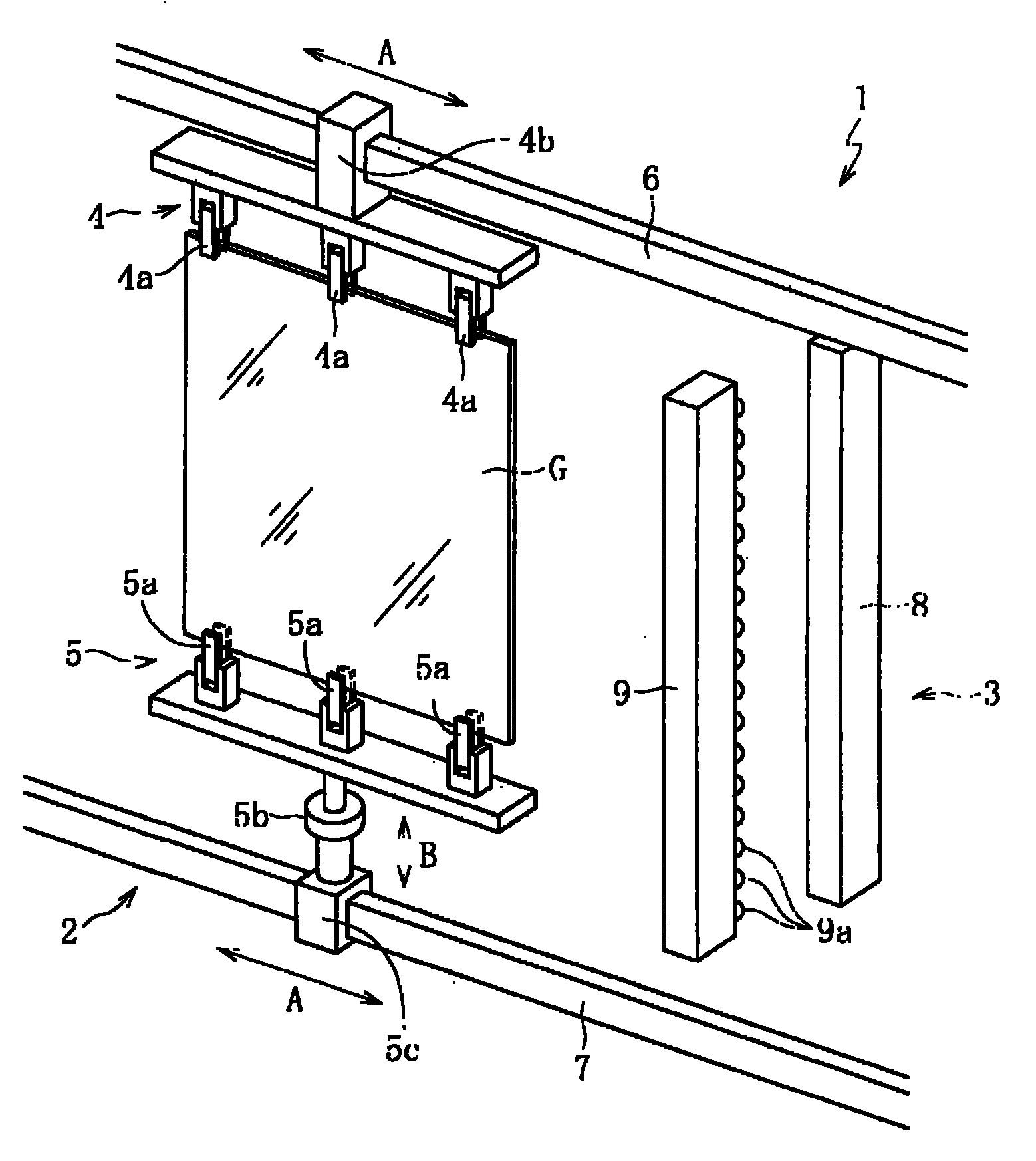

[0039] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

[0040] figure 1 It is a side view showing the overall structure of the glass substrate inspection apparatus of this embodiment. As shown in the figure, this glass substrate inspection apparatus 1 includes: a moving mechanism 2 that moves the glass substrate G in a vertical posture (approximately vertical posture in the illustration); The defect detection mechanism 3 that detects defects of the glass substrate G on the moving path. Moreover, as glass substrate G, the glass substrate for liquid crystal displays whose thickness is 0.05-1.8 mm and the size of one side is 1 m or more is mentioned, for example.

[0041] The above-mentioned moving mechanism 2 is provided with: an upper holding mechanism 4 for holding the top of the glass substrate G; a lower holding mechanism 5 for holding the lower edge of the glass substrate G; An upper guide rail 6 for guiding; a lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com