A kind of helical correction type anti-bending cable

A bending-resistant and helical technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems that the cables cannot be used in normal production, it is difficult to restore the original shape, and the cables are excessively bent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

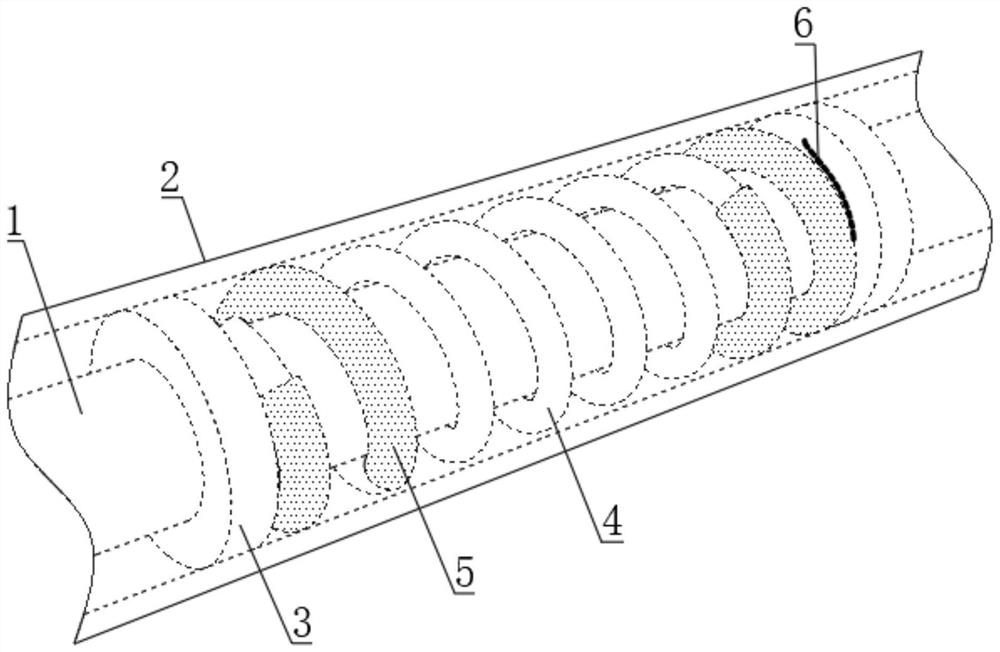

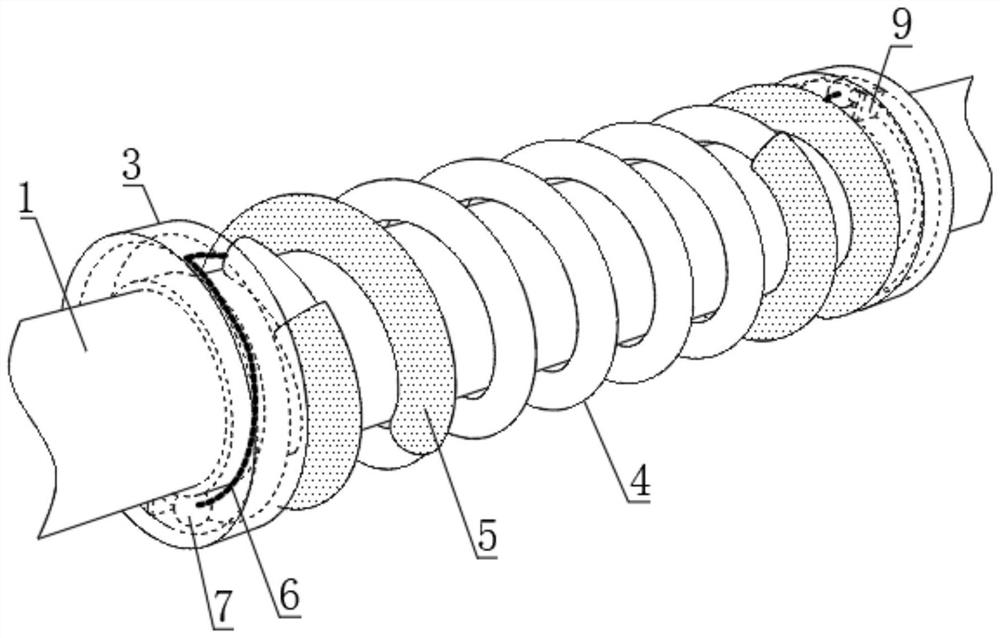

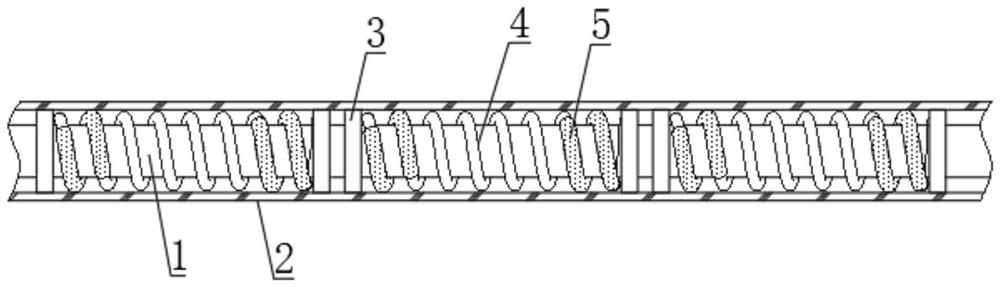

[0045] see figure 1 , figure 2 and image 3 , a helical correction type anti-bending cable, including a cable core 1, the outer side of the cable core 1 is covered with an outer sheath 2, and a plurality of evenly distributed helical correction sleeves are arranged between the cable core 1 and the outer sheath 2, and the spiral The correction sleeve includes a pair of dividing rings 3 and a coil spring bar 4 located between the pair of dividing rings 3. The material of the dividing ring 3 and the coil spring bar 4 is one of TPU, TPE or TPR. The dividing ring 3 The inner and outer ends of the coil spring are fixedly connected to the cable core 1 and the outer sheath 2 respectively. The inner and outer diameters of the coil spring bar 4 are located between the outer diameter of the cable core 1 and the inner diameter of the outer sheath 2. The outer diameter of the coil spring bar 4 A pair of gas storage sleeves 5 are fixedly connected at the ends, and the pair of gas storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com