Exposure device and exposure method

A technology of exposure device and light source, which can be applied in the direction of photolithography exposure device, microlithography exposure equipment, photolithography mask, etc., can solve problems such as bending and exposure accuracy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

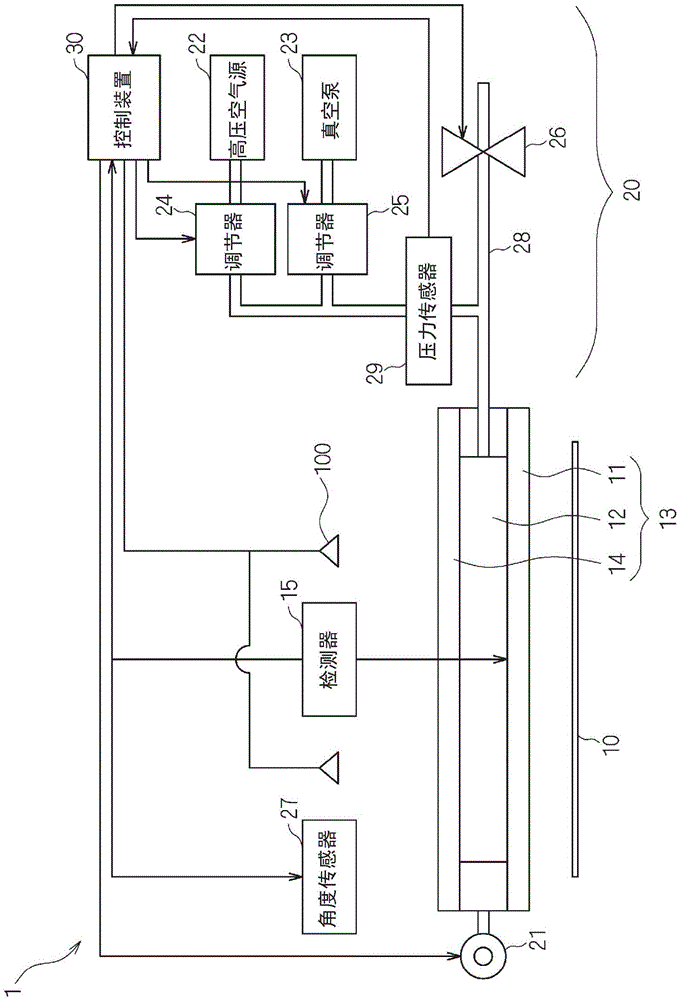

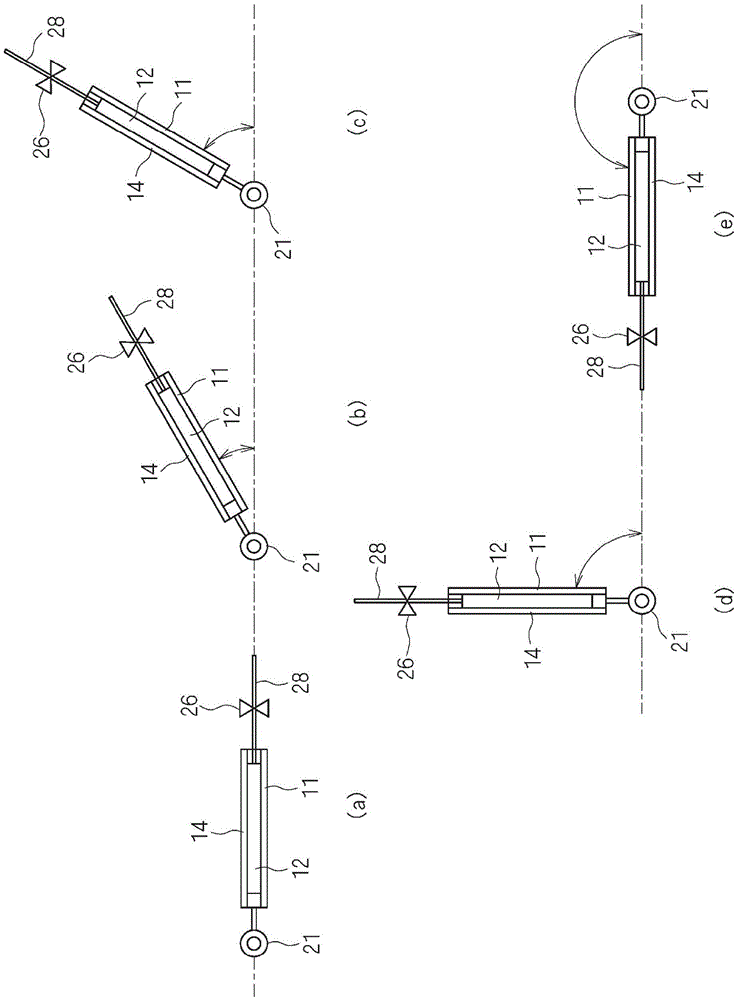

[0035] In the exposure apparatus according to Embodiment 1 of the present invention, in order to improve exposure accuracy, after adjusting the pressure (internal pressure) in the airtight space with the mask holder holding the optical plate tilted, the mask holder is restored to its original value. angle to expose the mask pattern on the workpiece 10 . Thus, the exposure apparatus according to Embodiment 1 includes a tilt mechanism at one end of the mask holder for tilting the mask holder holding the optical plate on which the mask pattern is provided. figure 1 It is a schematic diagram which shows the structure of the exposure apparatus concerning embodiment of this invention. in addition, figure 1 In , the imaging device and markers necessary for alignment with the workpiece are omitted, and only the structure necessary for adjusting the distance between the optical plate and the workpiece is described.

[0036] figure 1 Among them, the exposure apparatus 1 according to ...

Embodiment approach 2

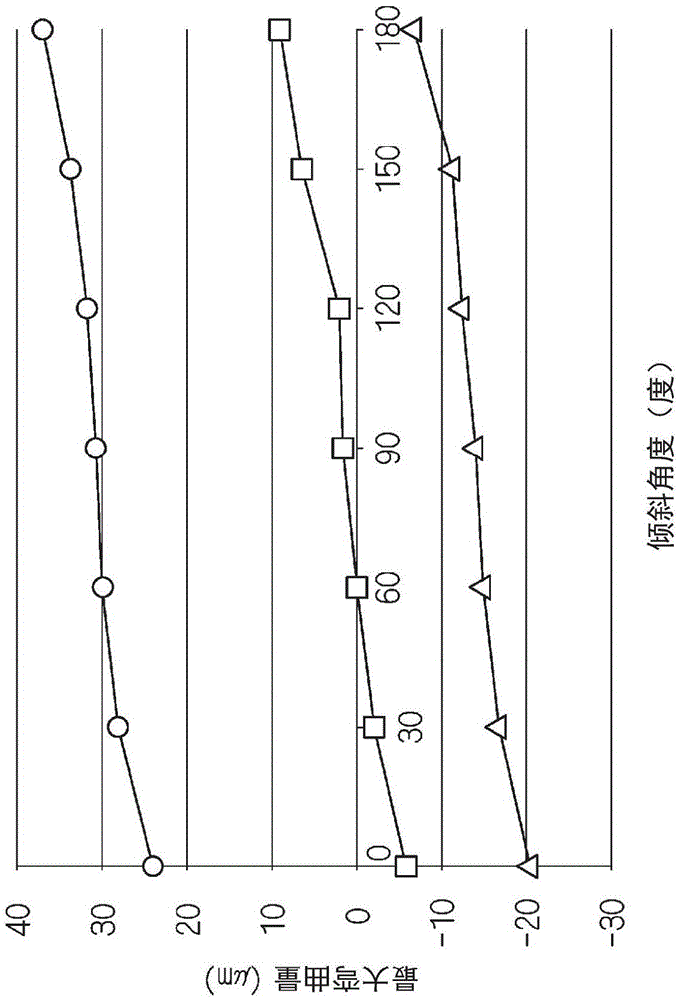

[0052] Since the configuration of the exposure apparatus according to Embodiment 2 of the present invention is the same as that of Embodiment 1, the same reference numerals are assigned and detailed description thereof will be omitted. Exposure apparatus 1 according to Embodiment 2 of the present invention differs from Embodiment 1 in that, according to image 3 In the shown relationship between the inclination angle of the mask holder 13 and the maximum amount of curvature of the optical plate 11 during exposure, for each inclination angle of the mask holder 13, the maximum amount of curvature of the optical plate 11 during exposure is determined to be zero. It is necessary to provide pressure into the airtight space 12 and store it.

[0053] That is, in the exposure apparatus 1 according to Embodiment 2 of the present invention, for each inclination angle of the mask holder 13 , the amount of deflection that needs to be supplied to the airtight space 12 in order to make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com