Interactive deformation and measurement simulation method for manually measuring girth of nonrigid limb

A simulation method and interactive technology, applied in the measurement devices of feet or shoe lasts, clothing, footwear, etc., can solve the problems of accuracy impact, a lot of time, and lack of surface reconstruction algorithm for limb size, so as to meet the requirements of time, High measurement accuracy and good visualization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

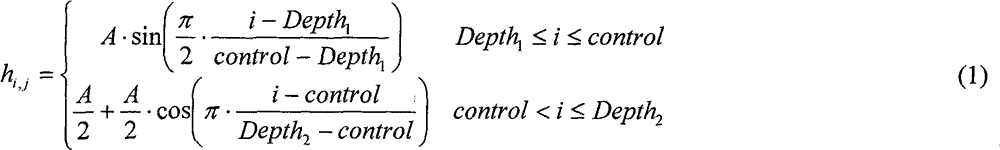

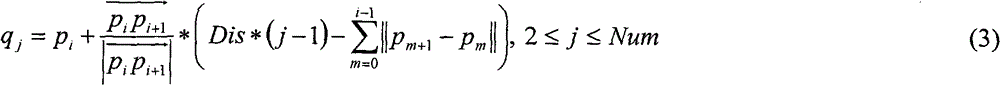

[0031] The interactive deformation and measurement simulation method for manual measurement of non-rigid limbs provided by the present invention specifically adopts a technical solution comprising the following steps:

[0032] 1. Obtain the 3D point cloud data of the limb surface through the laser scanner;

[0033] At present, three-dimensional digital equipment such as laser scanners have been widely used. It is an easy technical means to use laser scanners to obtain three-dimensional point cloud data on the surface of limbs; for example, Vorum three-dimensional foot scanners can be used to obtain human body The point cloud data of the foot, the device can provide high-definition foot shape at high speed; of course, the present invention is not limited to the scanning of the foot, any 3D point cloud data related to the surface of the limb can be obtained through the existing 3D Digitization equipment such as commercial laser scanners is obtained.

[0034] 2. Use the IPD algo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com