Double-resolution incremental position measuring device

A measurement device and technology of resolution, applied in the field of measurement, can solve the problems of increasing auxiliary measurement time, affecting production efficiency, increasing measurement cost, etc., and achieving the effects of low measurement cost, high efficiency and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

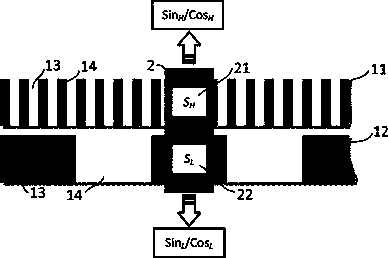

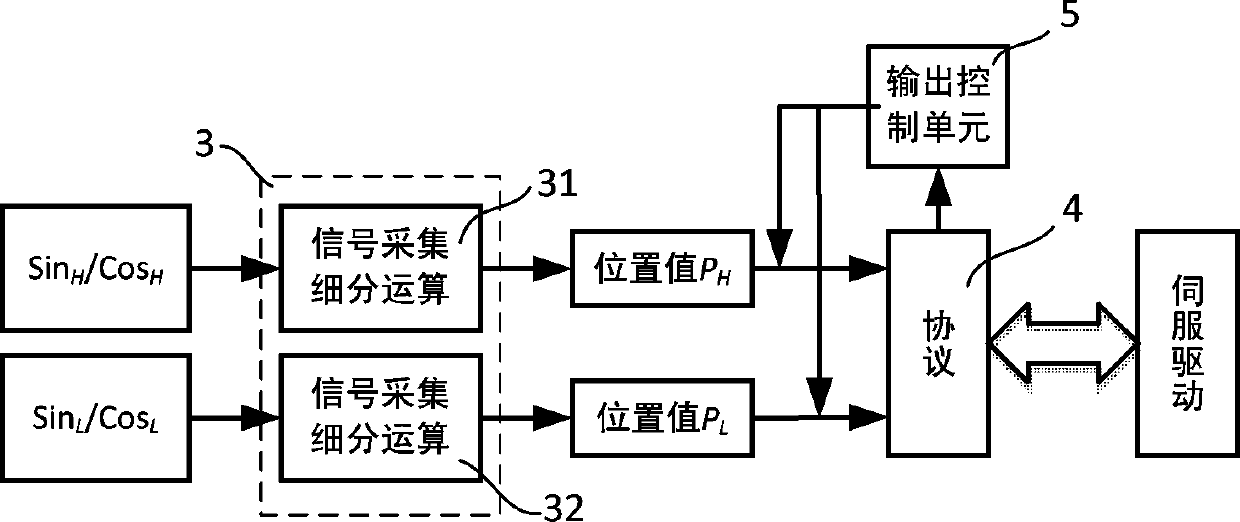

[0016] to combine figure 1 and figure 2 As shown, a dual-resolution incremental position measuring device of the present invention is composed of an incremental code track 11, an incremental code track 12, a reading unit 2, a signal processing unit 3, a protocol 4, and an output control unit 5 . Wherein, the incremental code track 11 and the incremental code track 12 constitute the measurement reference unit of the present invention.

[0017] Both the incremental code track 11 and the incremental code track 12 are composed of a uniform arrangement of the opaque area 13 and the light-transmitting area 14, and the number of lines in the incremental code track 11 is equal to the number of lines in the incremental code track 12. Integer multiples.

[0018] Reader unit 2 contains S H Sensing Module 21 and S L The sensing module 22 is used to read the position information of the incremental code track 11 and the incremental code track 12 respectively, and converts the optical ...

Embodiment 2

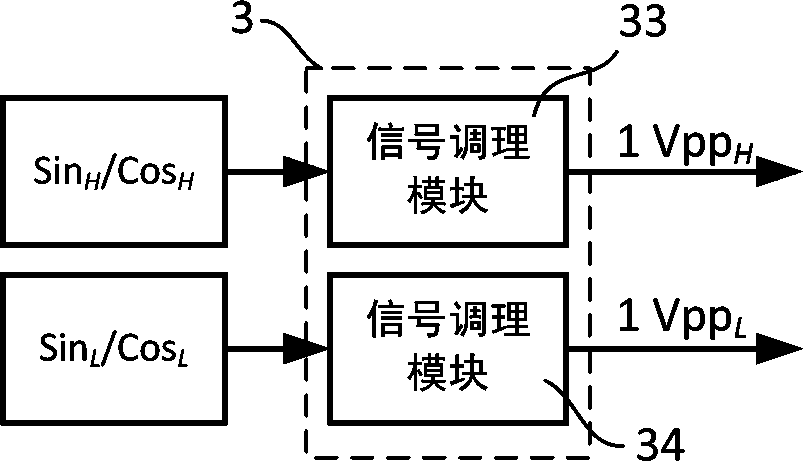

[0022] to combine figure 1 and image 3 As shown, a dual-resolution incremental position measuring device of the present invention is composed of an incremental code track 11, an incremental code track 12, a reading unit 2, a signal processing unit 3, a protocol 4, and an output control unit 5 . Wherein, the incremental code track 11 and the incremental code track 12 constitute the measurement reference unit of the present invention.

[0023] Both the incremental code track 11 and the incremental code track 12 are composed of a uniform arrangement of the opaque area 13 and the light-transmitting area 14, and the number of lines in the incremental code track 11 is equal to the number of lines in the incremental code track 12. Integer multiples.

[0024] Reader unit 2 contains S H Sensing Module 21 and S L The sensing module 22 is used to read the position information of the incremental code track 11 and the incremental code track 12 respectively, and converts the optical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com