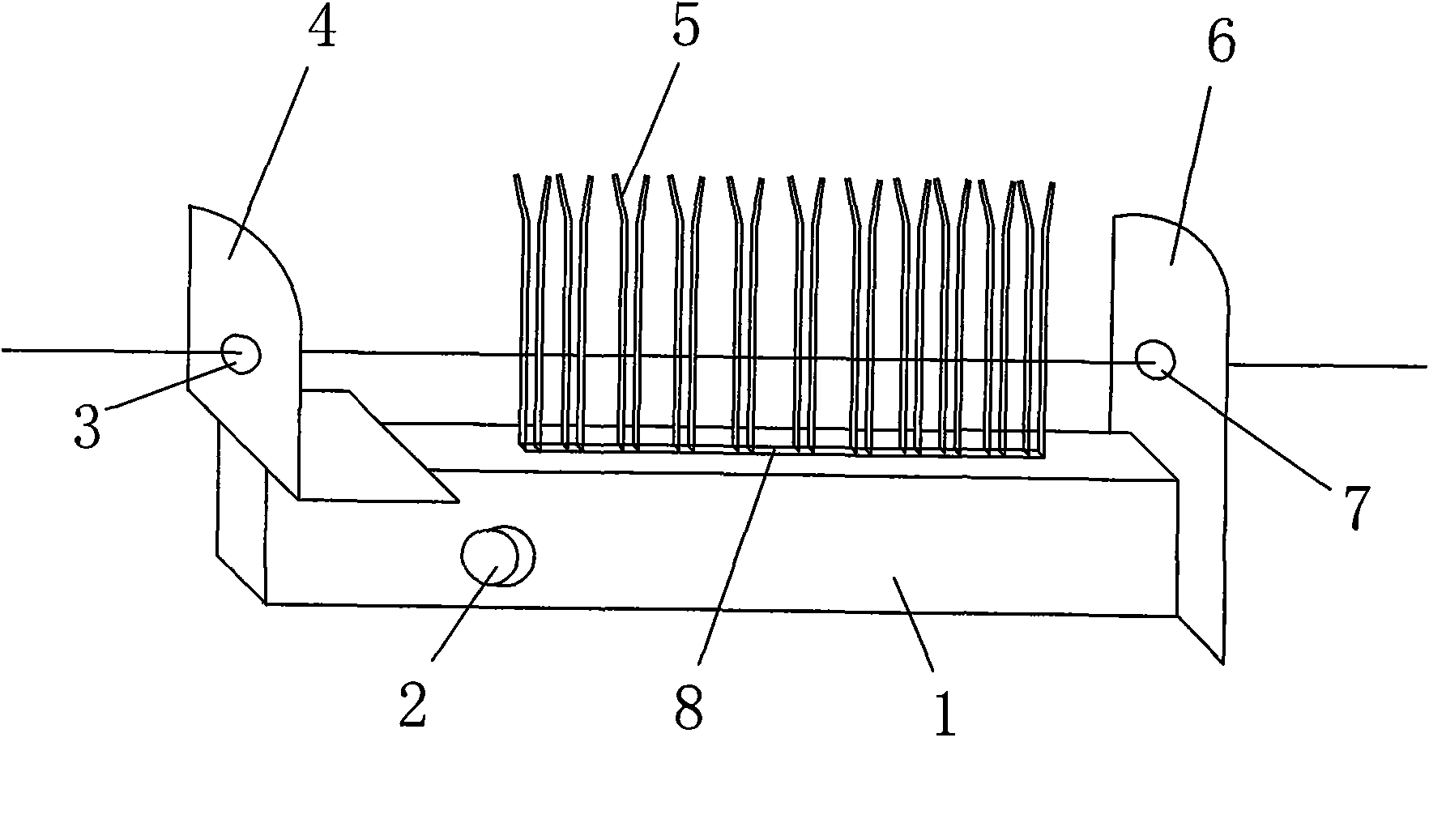

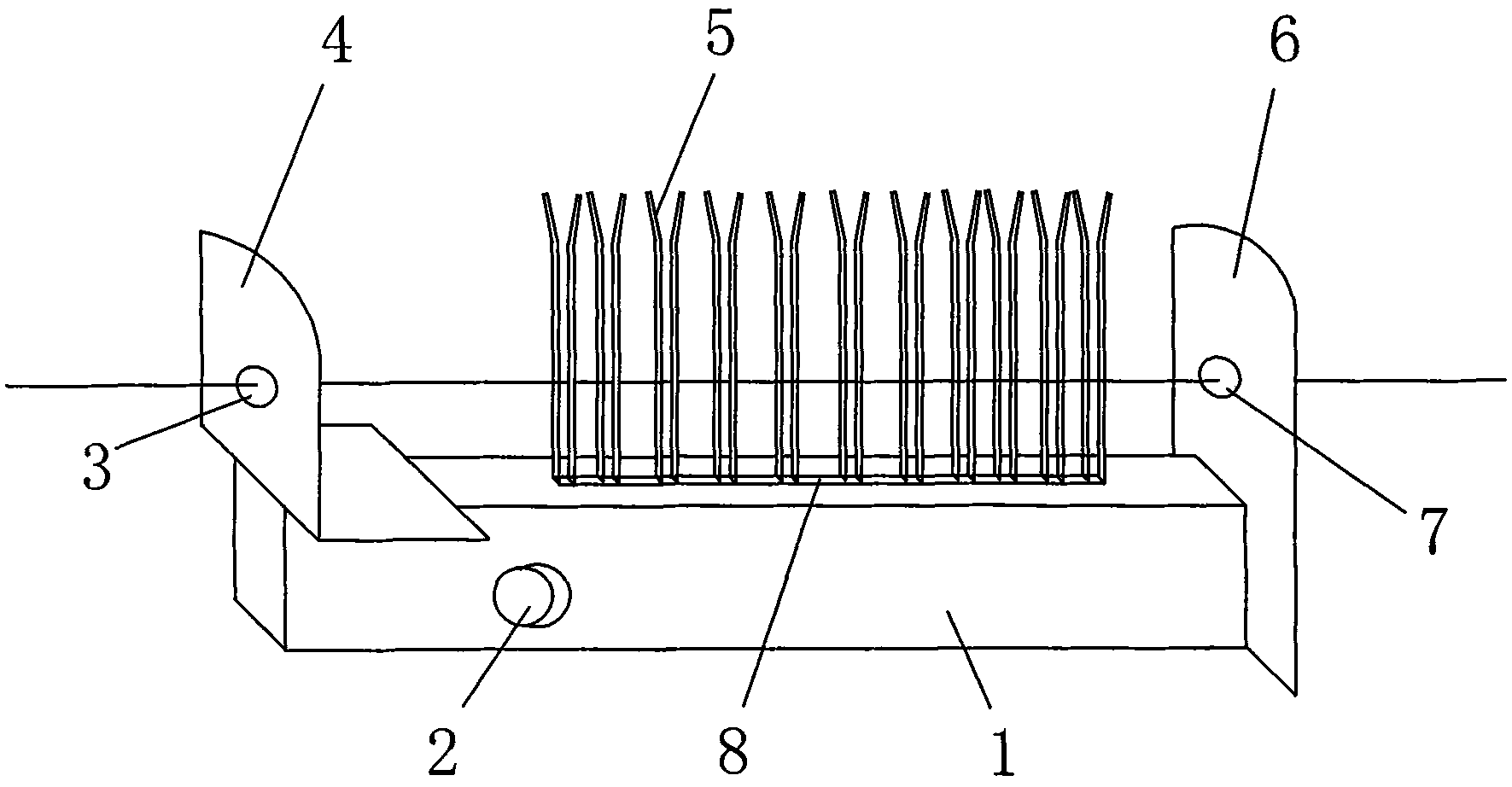

Comb-like weft yarn tensioner on rapier loom

A technology of yarn tension and rapier looms, which is applied in looms, textiles, textiles and papermaking, etc. It can solve the problems affecting the weaving output and opening efficiency, the reduction of nip tension, the increase of yarn hairiness and flying flowers, etc. problem, to achieve the effect of improving the efficiency and product quality of the platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] exist figure 1 In the embodiment of the present invention, the machine base 1 provided with the fixed screw hole 2 is fixed on the support of the weft feeder with screws, and one end of the machine base 1 is provided with an L-shaped yarn guide ceramic hole support plate 4, and the L-shaped guide The upper end of the yarn porcelain hole bearing plate 4 is provided with a yarn feeding guide porcelain hole 3, and the lower end of the L-shaped yarn guide porcelain hole bearing plate 4 is installed and fixed on one end of the machine base 1 with screws; at the other end of the machine base 1 The head is provided with a fixed support plate 6 for the yarn guide porcelain hole, and the upper end of the yarn guide porcelain hole fixed support plate 6 is provided with a yarn guide porcelain hole 7, and the lower end of the yarn guide porcelain hole fixed support plate 6 is installed and fixed on the machine base with screws 1; the comb-shaped teeth 5 made of chrome-plated steel ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap