Room-temperature-curable polyorganosiloxane composition

A technology of polyorganosiloxane and room temperature curing, which is applied in the field of room temperature curable polyorganosiloxane compositions, and can solve the problems of insufficient matting effect and adverse effects on the physical properties of cured products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

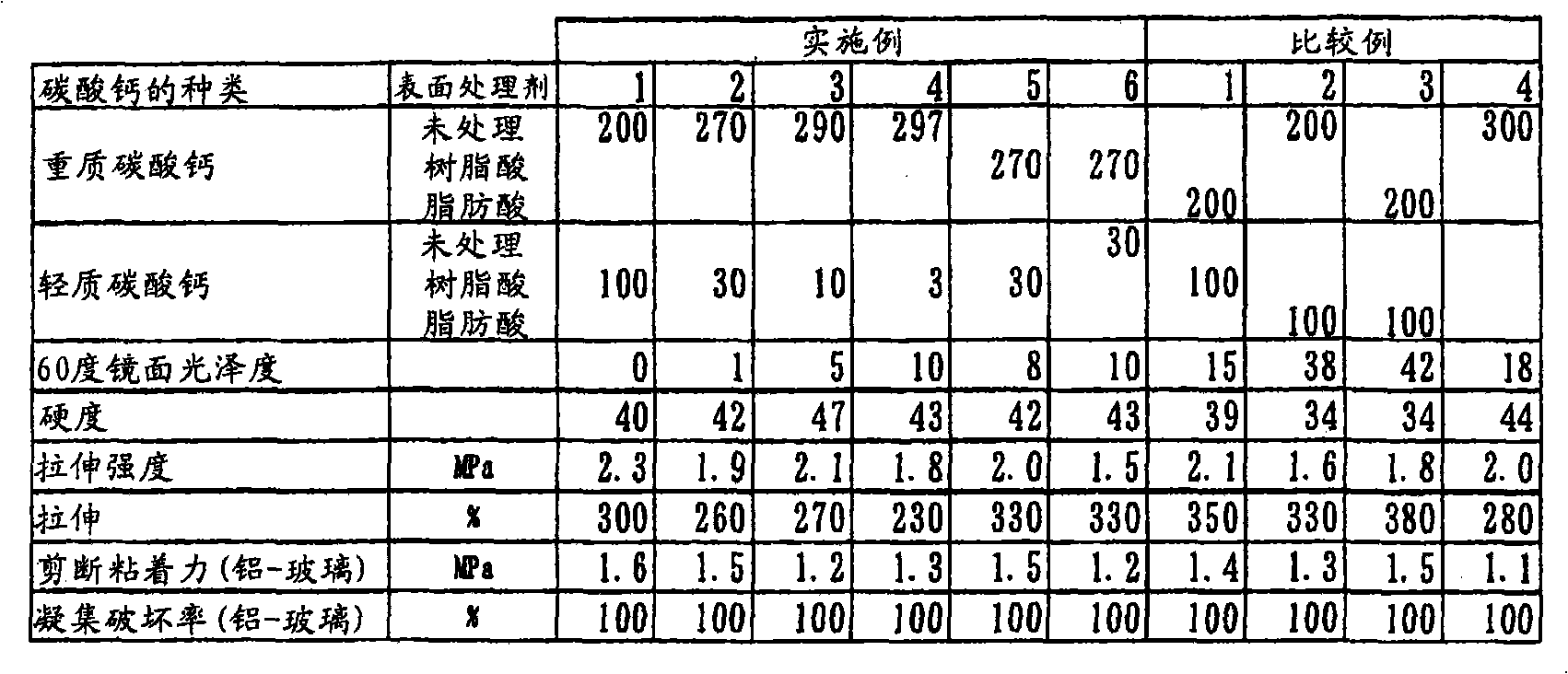

Examples

Embodiment 1

[0030] 100 parts of polydimethylsiloxane with a viscosity of 20,000 mPa·s at both ends of the molecular chain terminated by methyldimethoxysiloxy groups, untreated heavy calcium carbonate (manufactured by MARUOCALCIUM Co., Ltd. / ス一 パ-SS) 200 parts, 100 parts of light calcium carbonate (manufactured by Shiraishi Industry Co., Ltd. / Shiraishi TDD) through resin acid surface treatment, 2 parts of carbon black, and the two ends of the molecular chain with a viscosity of 100 mPa·s are treated with trimethylformaldehyde After 33 parts of siloxy-terminated polydimethylsiloxane are evenly mixed, mix 5 parts of methyltrimethoxysilane, 5 parts of diisopropoxybis(ethyl acetoacetate)titanium, and 1 part of isocyanuric acid, 1 part of 3,5-tris[3-(trimethoxysilyl)propyl]ester was used to prepare a one-component room temperature curable polyorganosiloxane composition.

[0031]On the Teflon (registered trademark) plate to which the obtained composition does not stick, place a mold having a thick...

Embodiment 2

[0034] Except that in embodiment 1, the untreated heavy calcium carbonate is changed into 270 parts, and the light calcium carbonate treated with resin acid surface is changed into 30 parts, and in the same manner as in embodiment 1, a one-component type room temperature curing method is prepared. Polyorganosiloxane composition.

Embodiment 3

[0036] Except that in embodiment 1, the untreated heavy calcium carbonate is changed into 290 parts, and the light calcium carbonate treated with resin acid surface is changed into 10 parts, and in the same manner as in embodiment 1, a one-component type room temperature curing method is prepared. Polyorganosiloxane composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com