Downhole load sharing motor assembly

A load sharing, motor technology, applied in wellbore/well components, electrical components, drilling equipment, etc., can solve problems such as impracticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

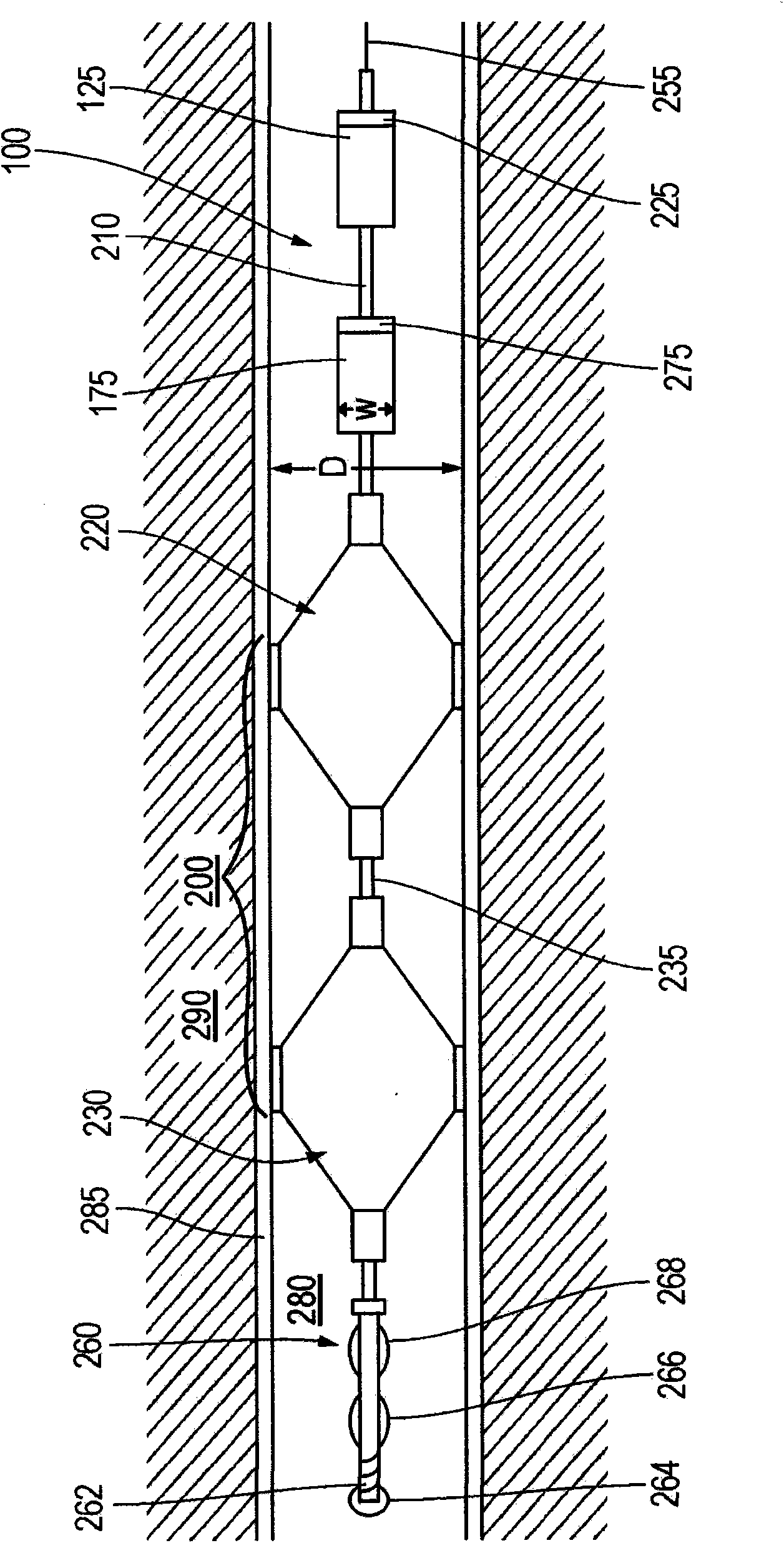

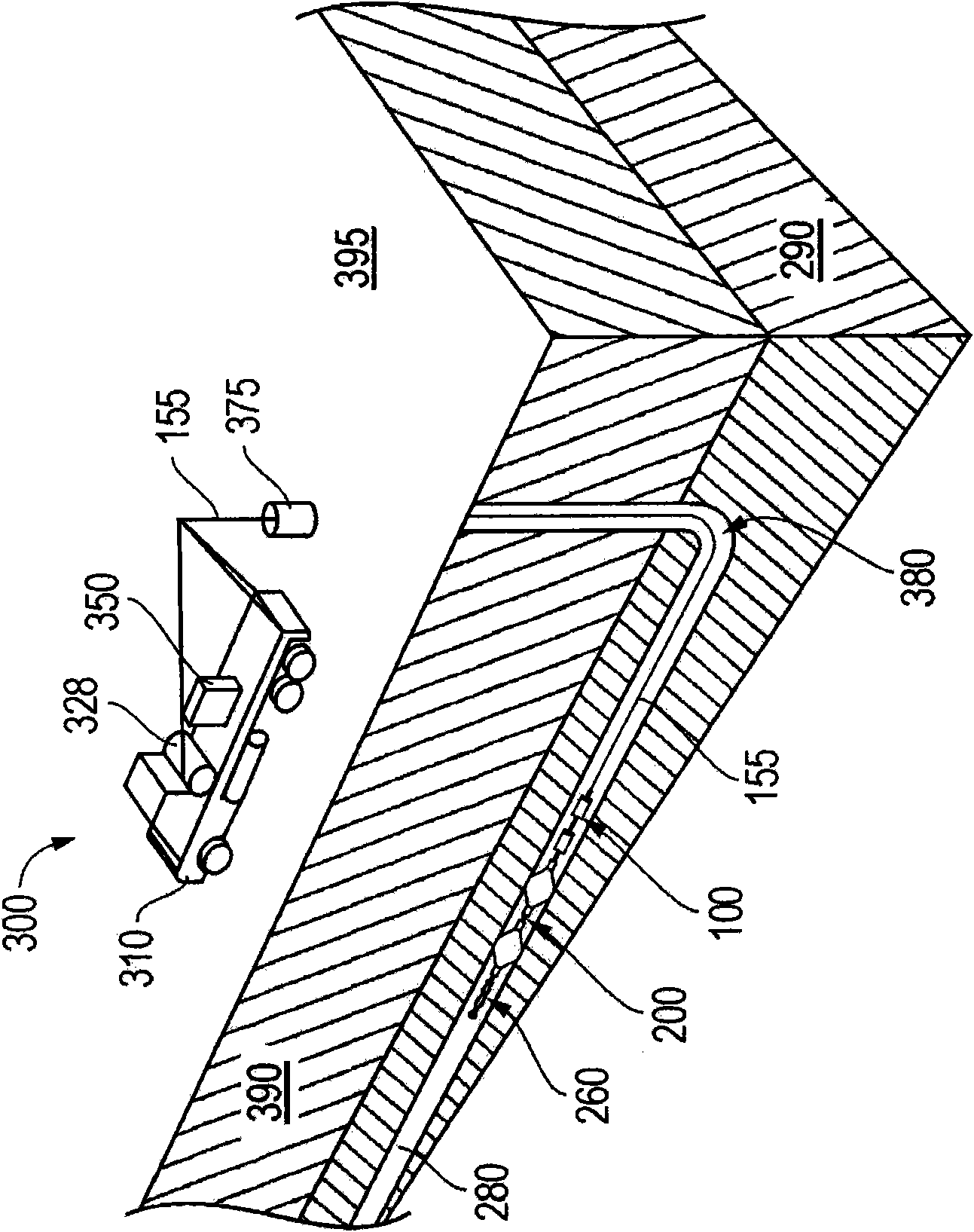

[0018] Embodiments are now described with reference to a particular downhole multi-motor assembly configured to share a load. Specifically, an assembly employing two permanent magnet synchronous machine (PMSM) motors will be described. However, other types of motor assemblies with different numbers of motors may also be used. For example, more than two motors may be used for the assembly. Regardless, embodiments described herein include assemblies with downhole PMSM motors, or other substantially constant speed adjustable speed motors configured to exhibit a generally balanced torque output during downhole operations. Furthermore, as used herein, the term "substantially constant speed adjustable speed motor" refers to a motor configured to operate at a substantially constant speed during operation, such as a conventional PMSM, but the term also actively directs the adjustment of speed during operation. its speed.

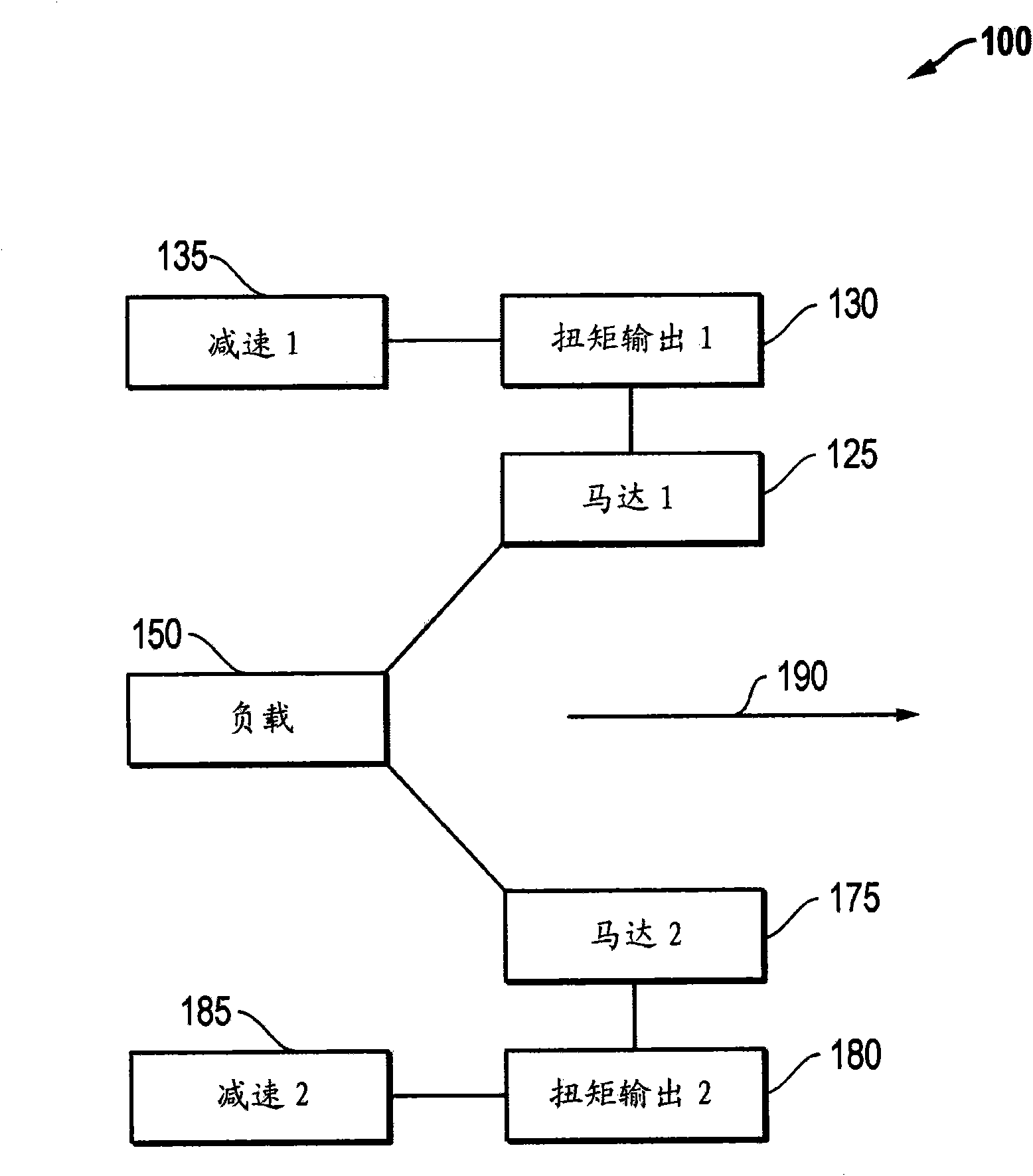

[0019] now refer to figure 1 , depicts a schematic diagram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com