Paper cutting mechanism

A paper cutting and cutting technology, applied in metal processing and other directions, can solve problems such as increasing costs, and achieve the effect of reducing costs and simplifying complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

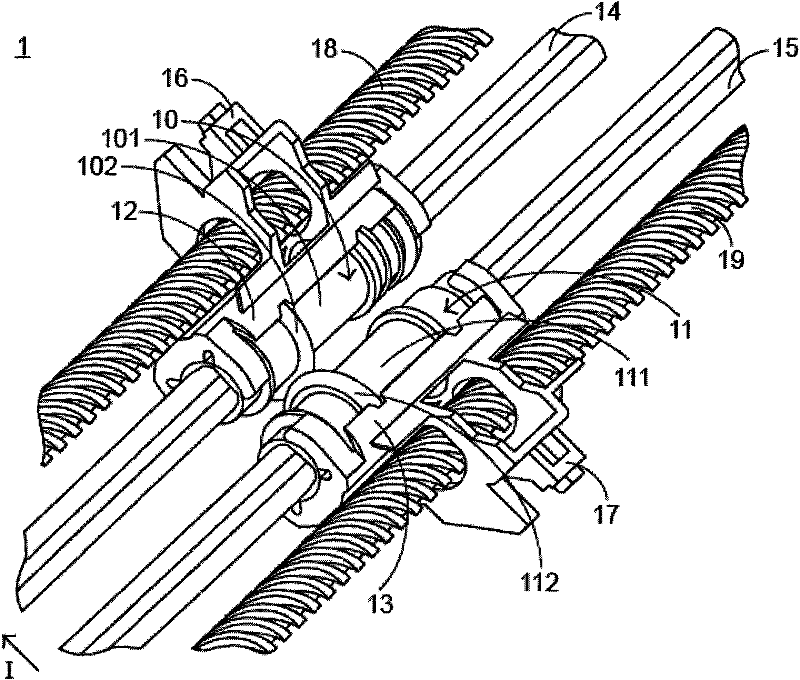

Image

Examples

Embodiment Construction

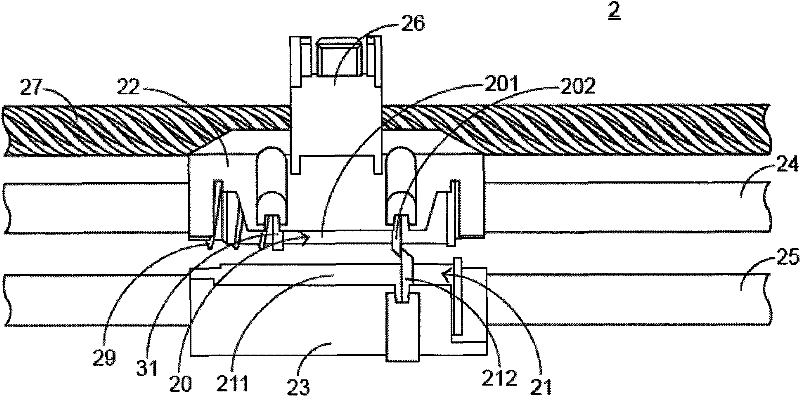

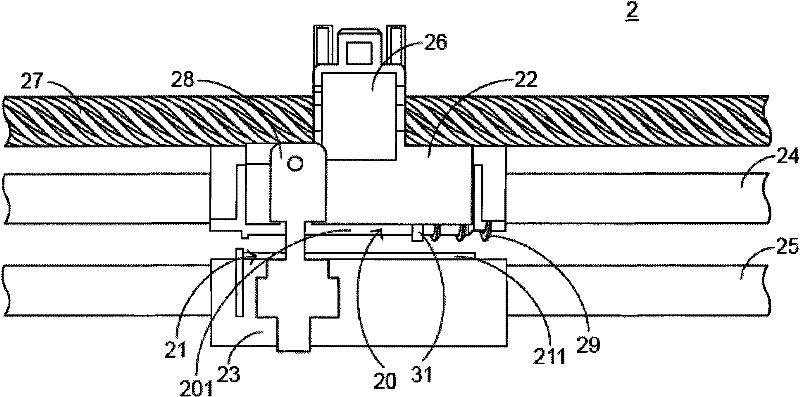

[0033] See figure 2 and image 3 , figure 2 It is a front view of the appearance structure of the preferred embodiment of the paper cutting mechanism of the present invention, image 3 It is a rear view of the appearance structure of the preferred embodiment of the paper cutting mechanism of the present invention. The paper cutting mechanism 2 of the present invention includes first and second cutter sets 20, 21, first and second cutter sets 22, 23, first and second guide shafts 24, 25, lead screw sleeve 26, and lead screw 27. The connecting device 28 and a spring 29. In addition, the first tool group 20 includes a first tool holder 201 and a first tool 202, and the second tool group 21 includes a second tool holder 211 and a second tool 212.

[0034] Wherein, the first guide shaft 24 passes through the first tool set 20, and the second guide shaft 25 passes through the second tool set 21, and the first and second tool sets 22 and 23 are respectively used to hold the first tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com