Energy-saving and high-efficiency double-row middle-seal full automatic bag-making machine

A fully automatic bag making machine, high-efficiency technology, applied in the direction of envelope/bag manufacturing machinery, paper/cardboard containers, containers, etc., can solve problems such as low efficiency, waste of energy, unfavorable market competition, etc., and achieve the goal of improving efficiency and saving energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

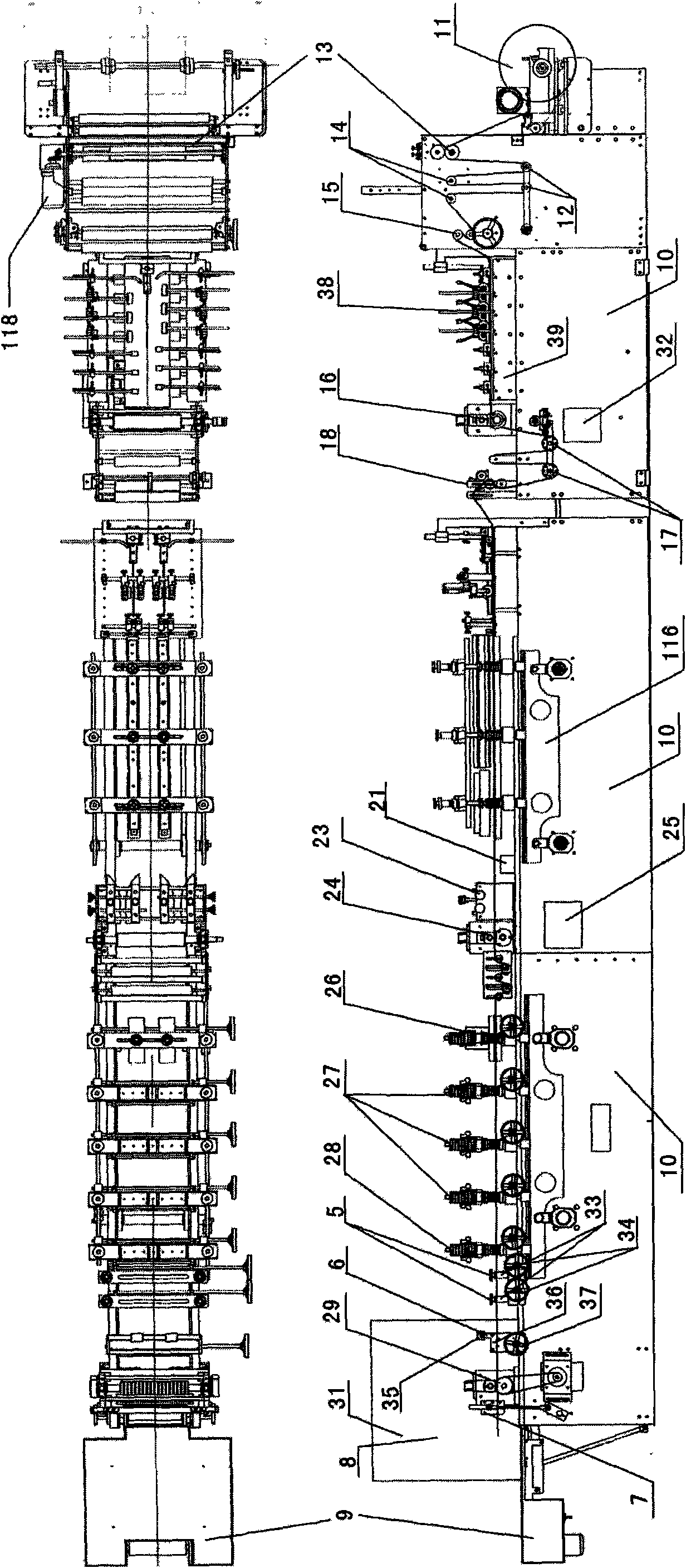

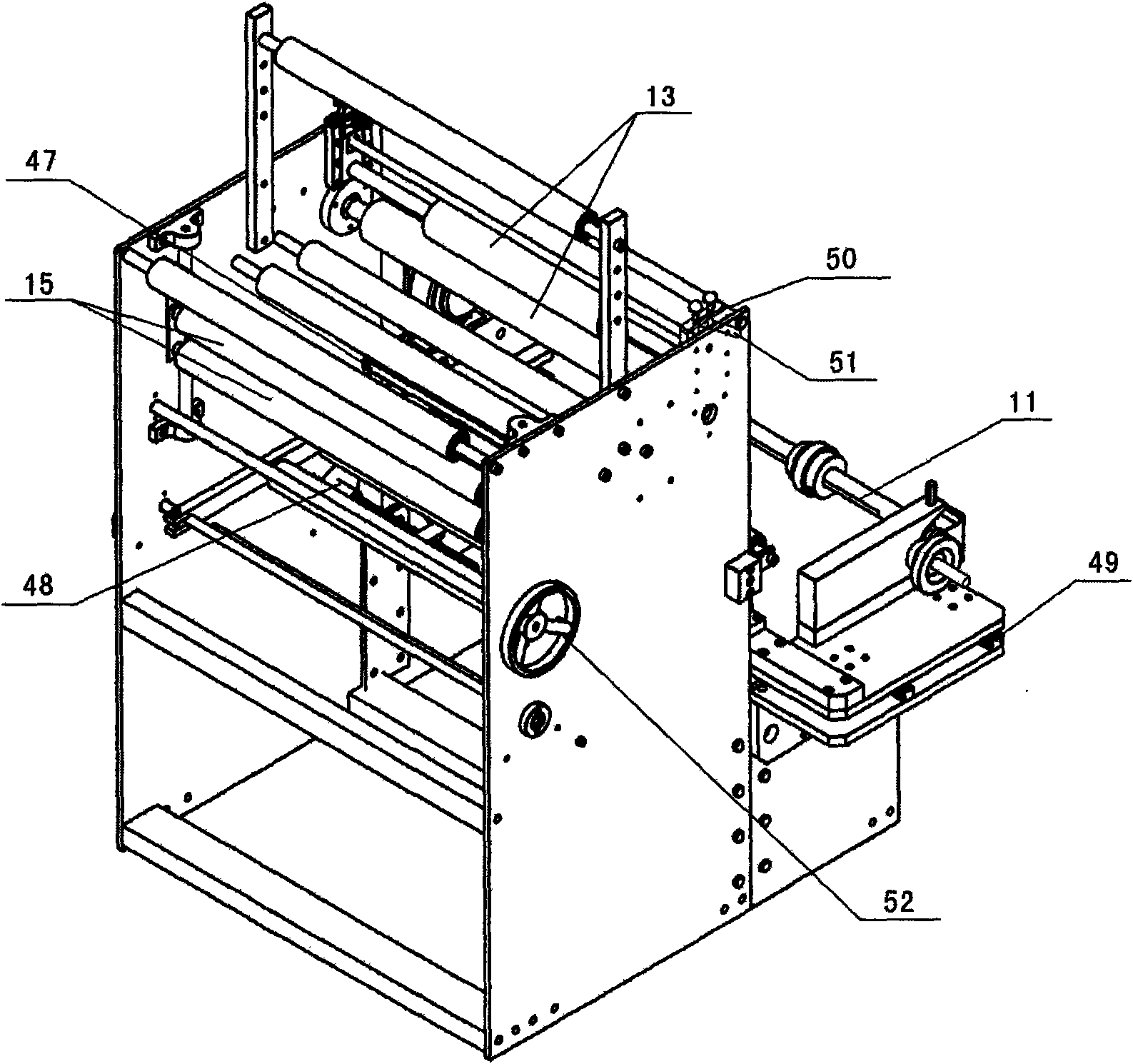

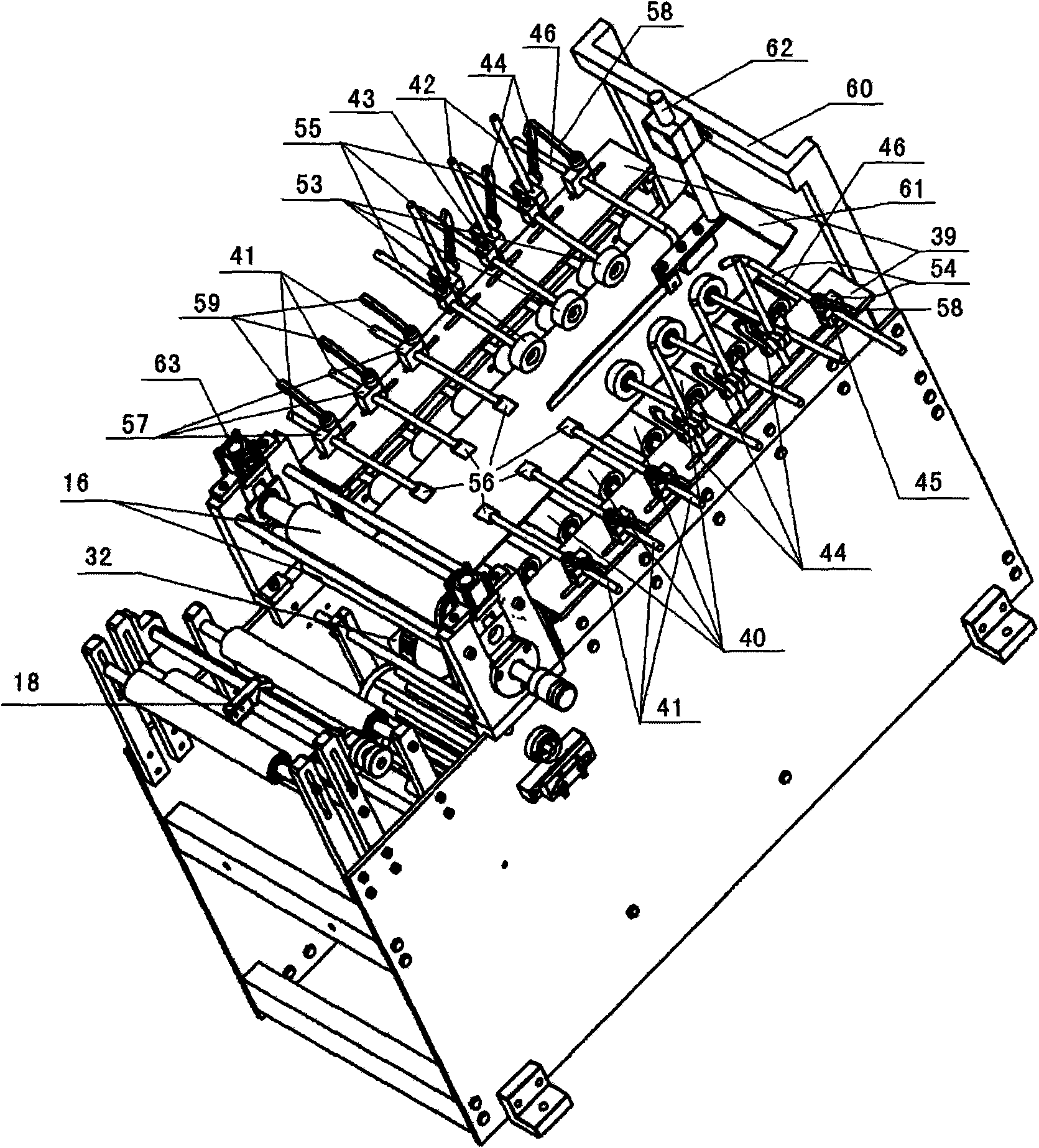

[0023] Such as Figure 1 to Figure 5 As shown, an energy-saving and high-efficiency double-row center-seal automatic bag making machine includes: a feeding device sequentially connected from front to back, a center-seal forming device installed on the body 10, a center-seal fork three-dimensional device, vertical and horizontal heat sealing Cold pressing device, punching device installation device 5, photoelectric eye device 6, cutter device 7, bag receiving and conveying table 9 connected to the tail end of the fuselage 10, and power supply device 8, four tractors A, B, C, and D motor and main drive motor. The feeding device includes wall panels on both sides, electric eye installation adjustment shafts 47 connected to both sides of the wall panels, a deviation correction motor 48 connected to one side of the wall panels, and a deviation corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com