Method and device for solving problem of inking fault of ball-point pen refills and pencil refills

A ballpoint pen refill and refill technology, which is applied in the repair of ink pens, printing, writing utensils, etc., can solve the problems of steel balls and refill ink drying, economic losses, and little effect, so as to restore smooth writing, protect the environment, and protect the environment. The effect of protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

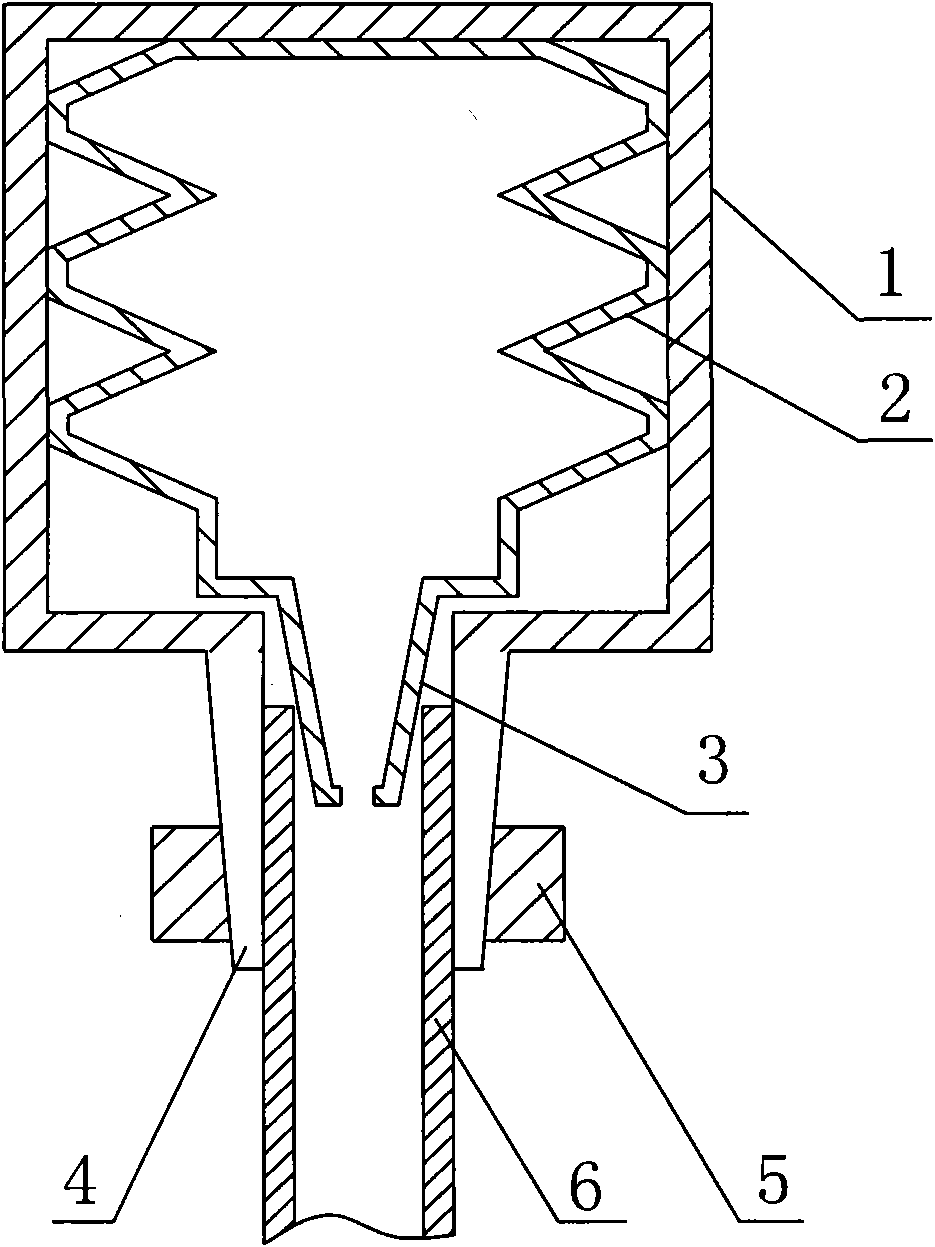

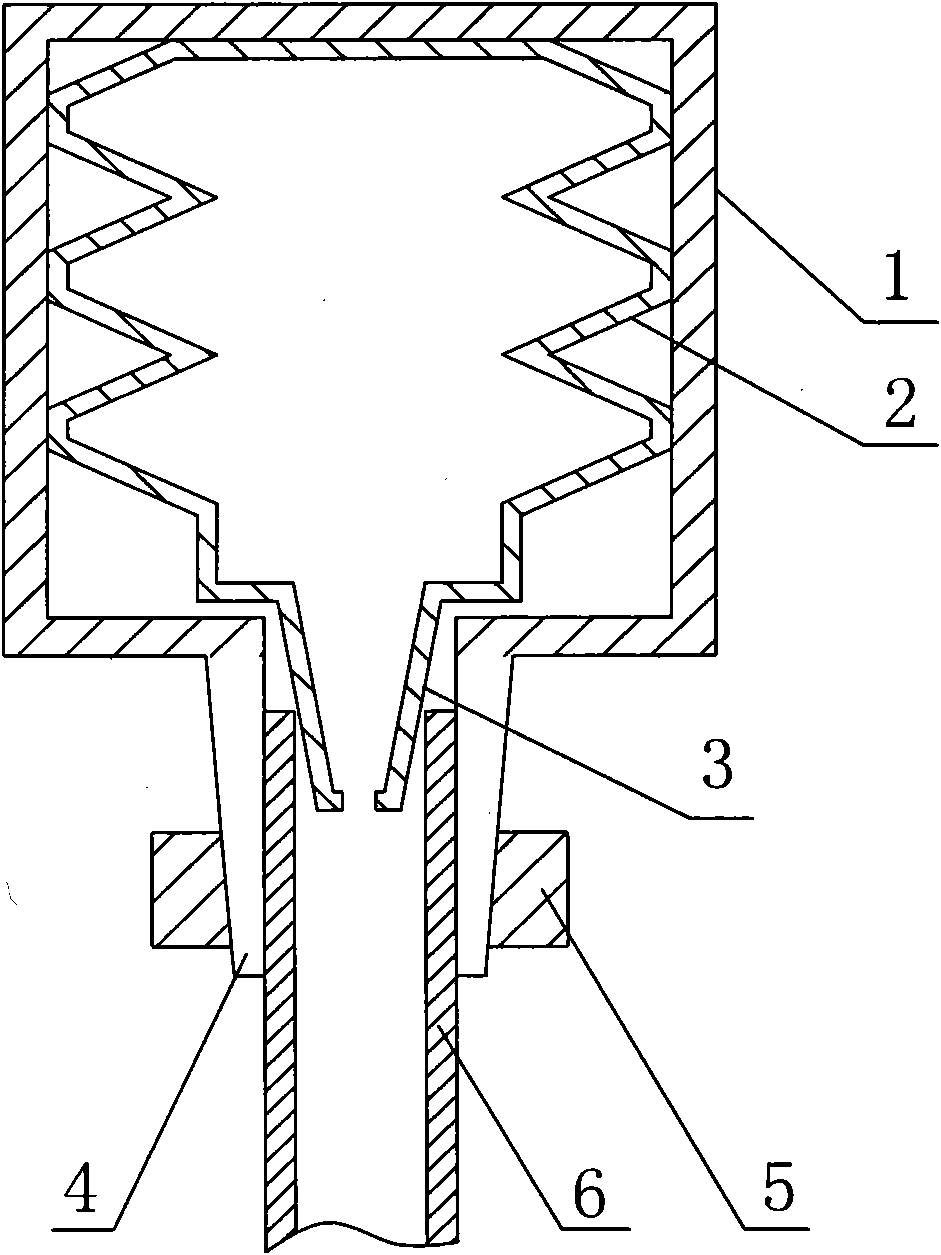

[0017] A kind of using method of the device that solves ball pen refill, pencil refill not to produce ink of the present invention is as follows:

[0018] Insert the nozzle at the end of the refill into the nozzle of the refill, and the tapered nozzle of the corrugated air bag is naturally inserted into the tail pipe of the refill. Since the refill tube and the tapered nozzle are made of plastic, they have good toughness and elasticity. The seal between the refill tube and the tapered nozzle can be well realized. The greater the pressure, the better the sealing effect. Insert the compressed corrugated air bag under the refill, so that the air in the corrugated air bag is compressed to generate pressure, and the compressed air passes through the tapered nozzle. Pressure is exerted inside the refill tube. Because the annular refill fixing collar locks the refill and the refill nozzle, the pressure in the corrugated air bag is constant. At this time, when using the refill to write...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com