Lamp bead carding device of LED display screen unit plate

A technology of unit boards and display screens, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of lack of arrangement of lamp beads, large amount of labor, and high cost, so as to reduce the amount of labor and reduce production costs , The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

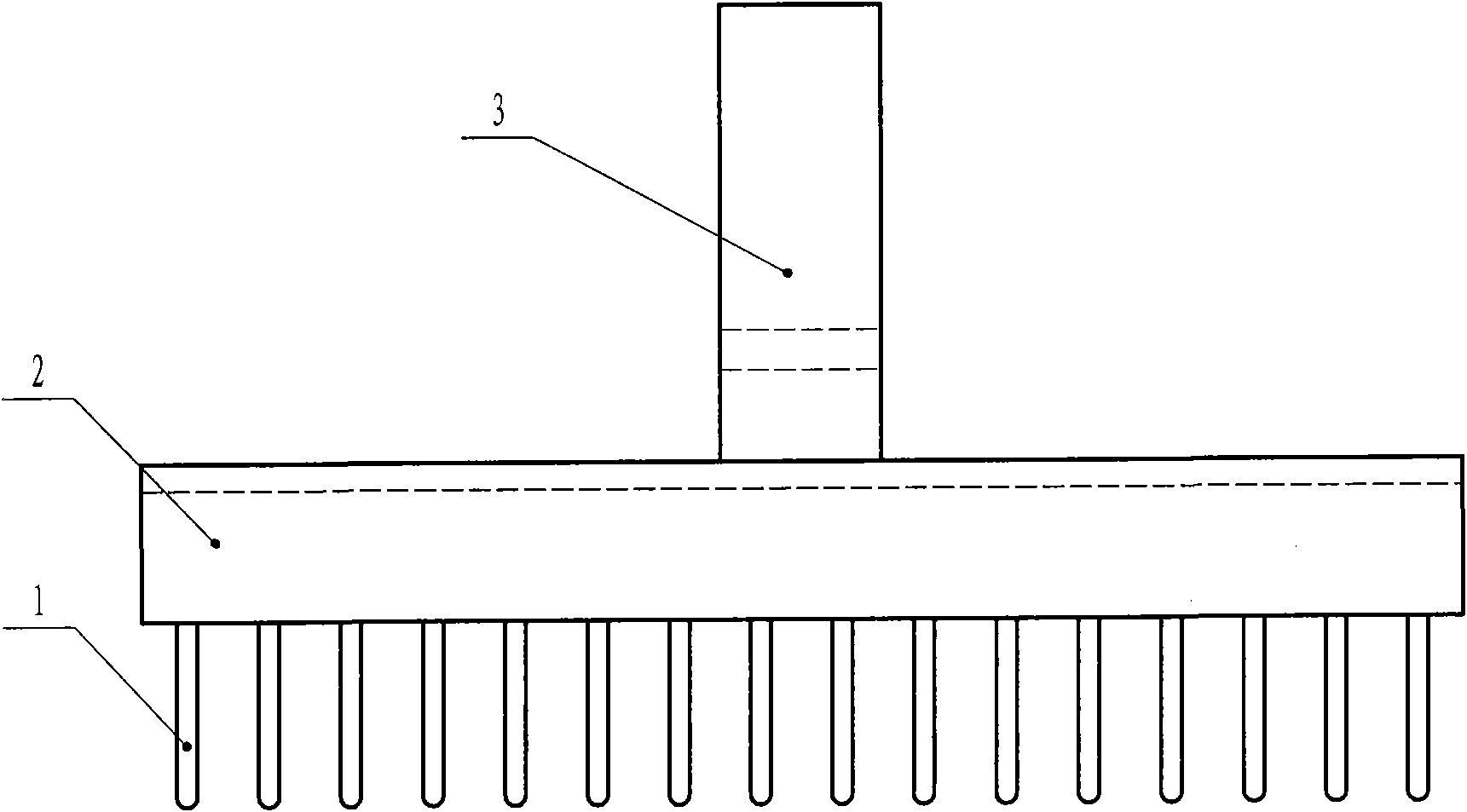

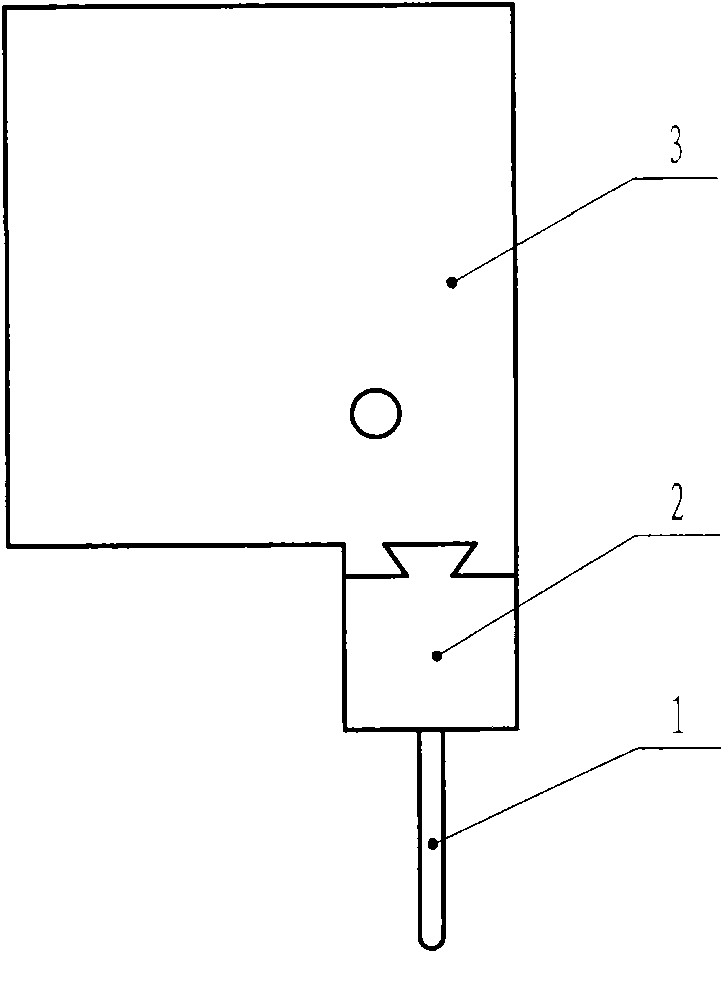

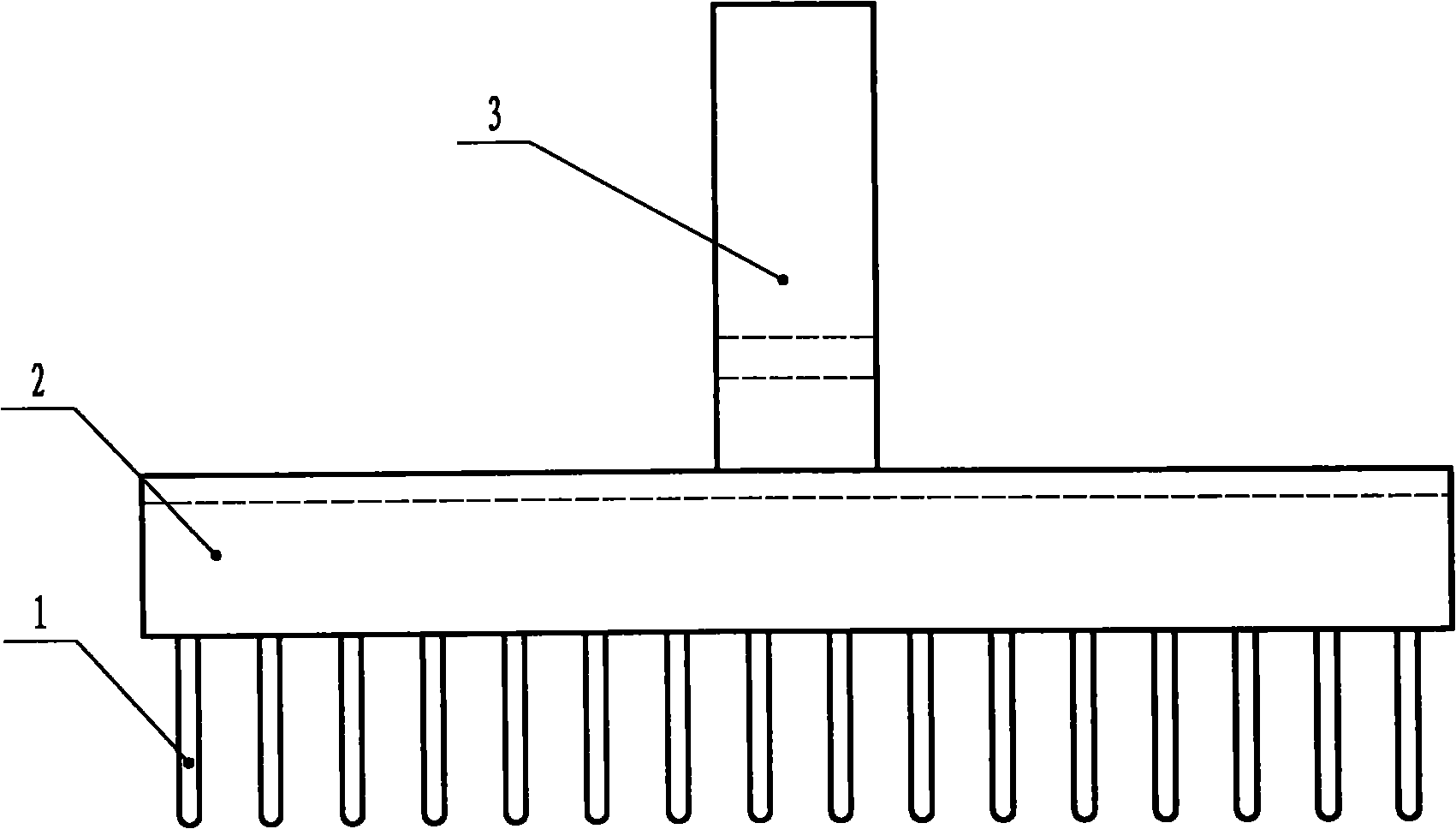

[0012] Such as figure 1 , figure 2 As shown, the light bead carding device for the LED display unit board of the present invention includes comb teeth 1, rack 2 and fixing frame 3, a plurality of comb teeth 1 are fixed at the bottom of the rack 2 at equal intervals, and the top of the rack 2 is dovetail-shaped The boss, the bottom of the fixed frame 3 has a dovetail groove, the dovetail shaped boss on the top of the tooth frame 2 is fixed in the dovetail groove at the bottom of the fixed frame 3, and the side of the fixed frame 3 has a mounting hole.

[0013] Since the group spacing of the lamp beads on the LED display unit board is not necessarily all equal, so to make multiple different types of LED display unit board lamp bead sorting devices, first determine according to the group distance of the lamp beads on the LED display unit board The spacing between the comb teeth 1, so as to make the corresponding type of LED display unit board lamp bead carding device, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com