Method for determining bearing capacity of concrete-filled steel tube under various stressing conditions and application thereof

A technology for determining the method of concrete-filled steel tubes, which is applied to underwater structures, instruments, bridges, etc., and can solve problems such as inability to determine the bearing capacity of concrete-filled steel tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0069] Such as figure 1 Shown, the specific embodiment of the present invention is as follows:

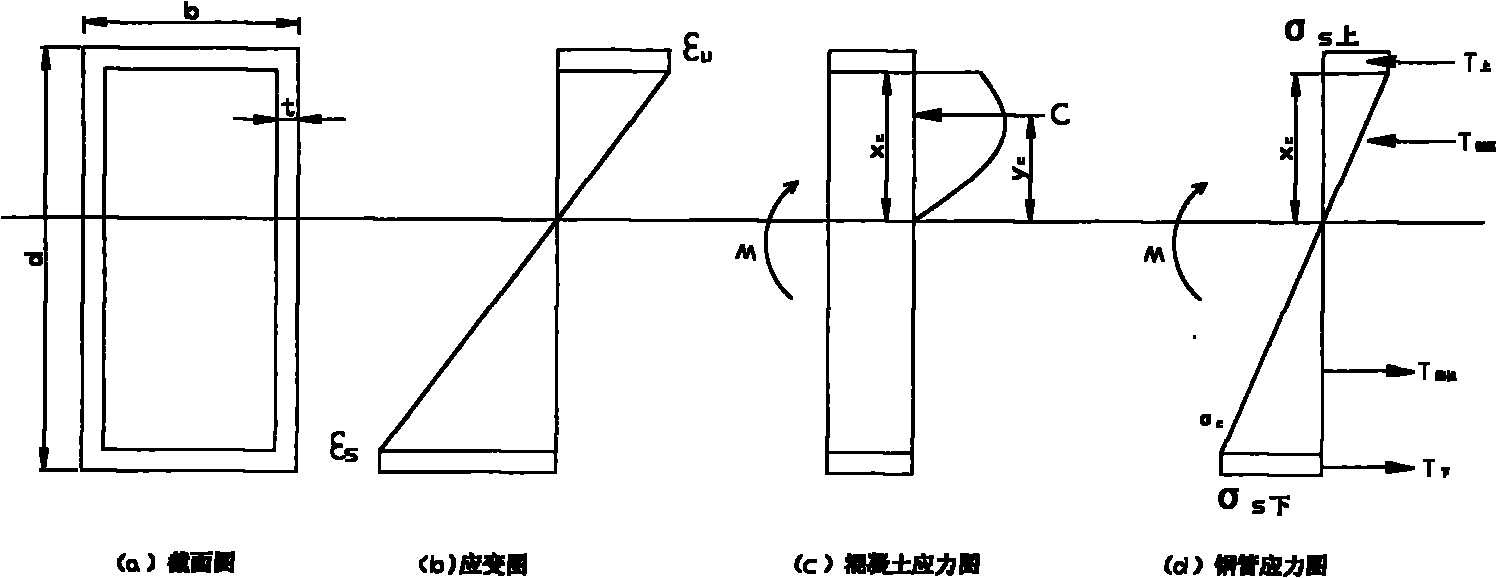

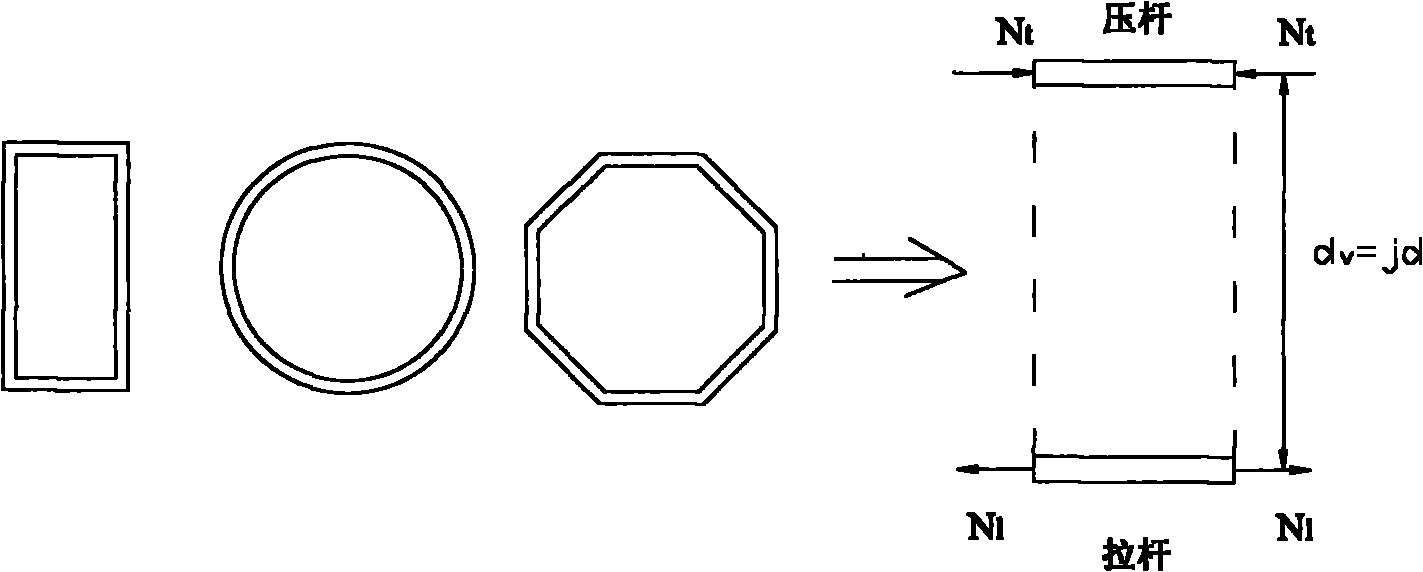

[0070] The invention provides a method for determining the bearing capacity of concrete-filled steel tubes under various stress conditions, characterized in that, the concrete-filled steel tubes are subjected to pressure, bending moment, shear force and torque, and the safety assessment method for concrete-filled steel tubes comprises the following steps:

[0071] Step 100: Collect relevant parameters of CFST: collect design values of steel and concrete compressive strength in CFST, collect cross-sectional areas of steel pipes and concrete in CFST;

[0072] Step 200: Determine the bearing capacity of the CFST. Under the action of pressure, bending moment, shear force and torque, the bearing capacity of the concrete filled steel tube concrete is satisfied by the following equation:

[0073] Time:

[0074]

[0075] Time;

[0076]

[0077] To determine the bearing capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com