Device for mechanically decoupled attachment of an aircraft component having hot gas flowing through the same

A technology of aircraft parts and hot air, applied to aircraft parts, exhaust devices, jet propulsion devices, etc., can solve problems such as damage, and achieve the effect of compensating for position and angle deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] For a better understanding, the device according to the present invention is described below as an embodiment, which is integrated in an Airbus A400M military transport aircraft, for example. The device according to the invention is not restricted to the mechanical decoupling of APU-exhaust ducts, but can also be used in other aircraft systems in which hot air is to be discharged via ducts.

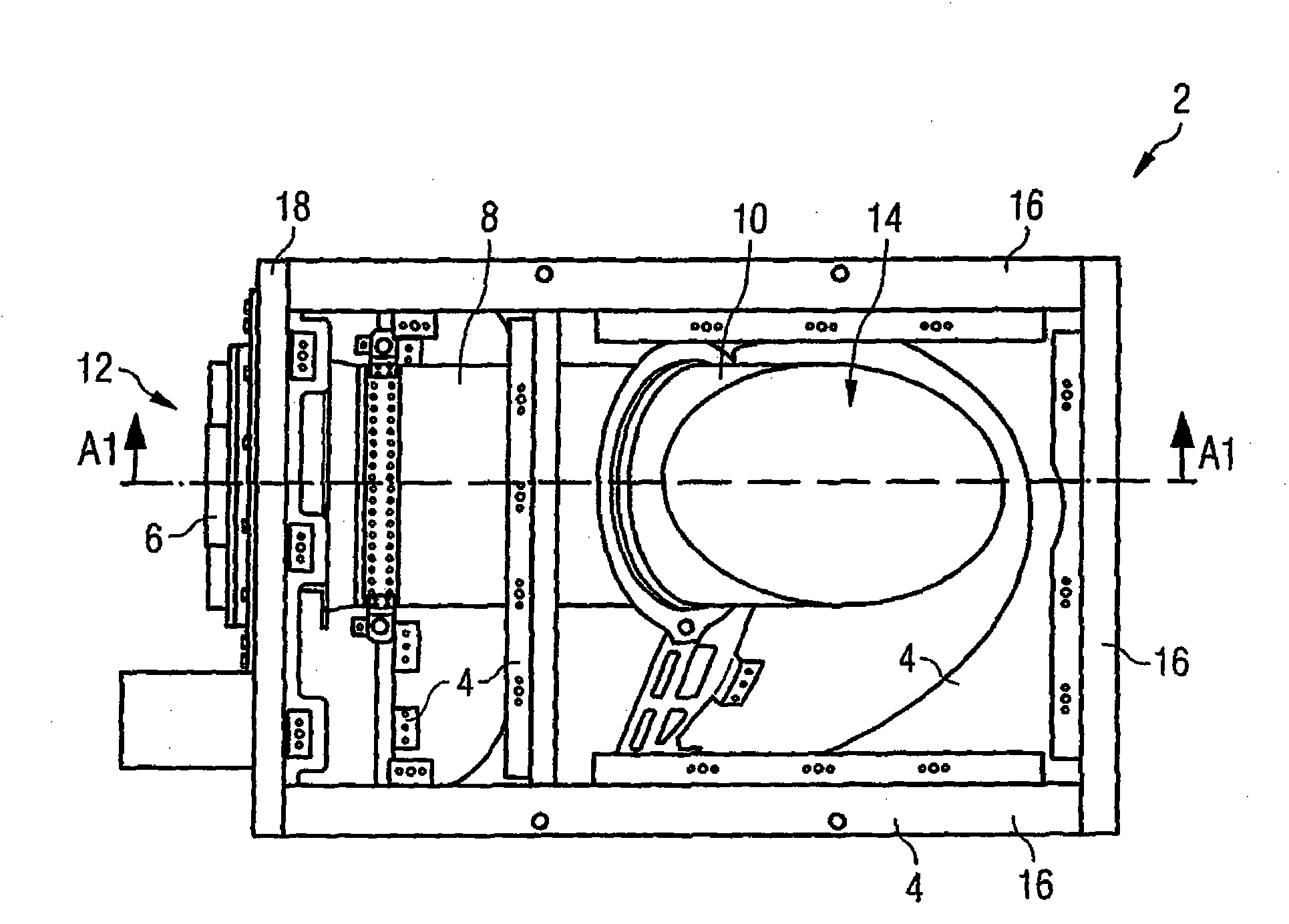

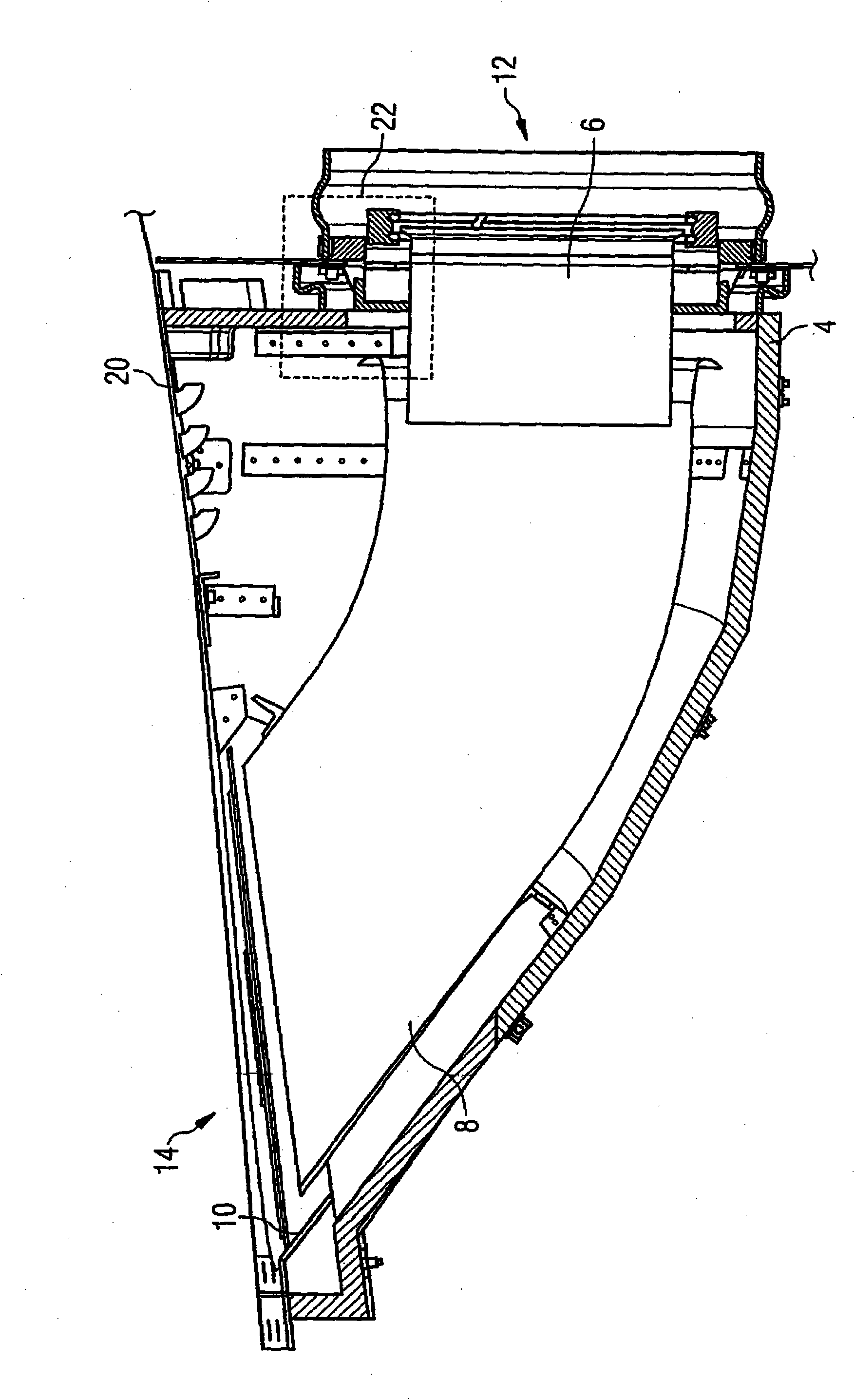

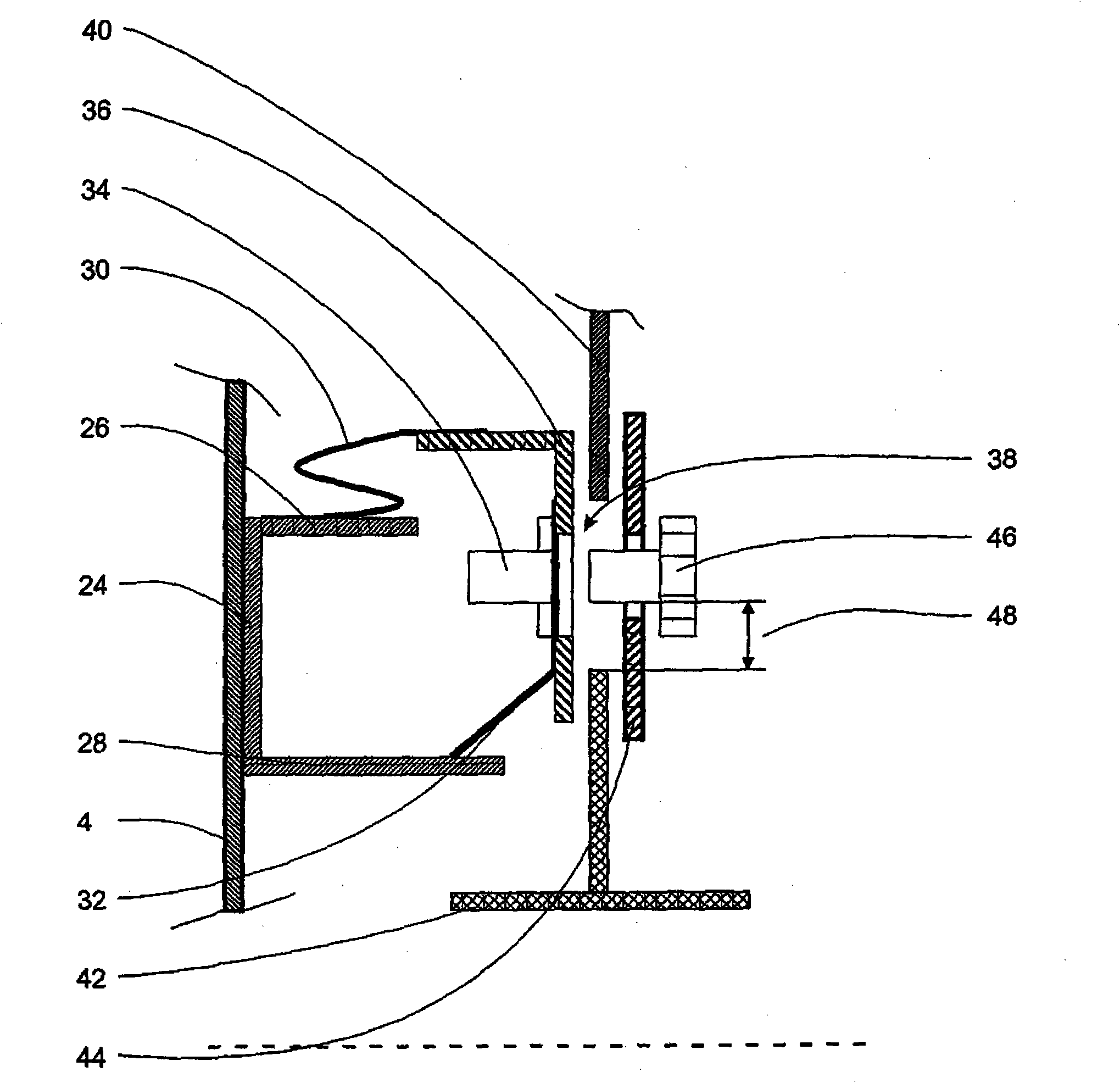

[0019] figure 1 An exhaust system 2 is shown, at which the housing cover installed during operation has been removed for better illustration. The exhaust system 2 comprises a housing 4 formed of sheet metal slots, stiffening members, brackets and fittings and an exhaust duct, in the example, consisting of three continuous exhaust ducts 6, 8 and 10, leading outwards from an exhaust inlet 12 Extends into the housing 4. The exhaust gas line 6 guides the exhaust gas from the APU at the exhaust gas inlet or connection 12 into the exhaust system 2, where the exhaust gas enters the exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com