Infrared radiation heat flow density reinforcement device for high temperature pneumatic thermal simulating test of missile

A technology for aerodynamic simulation of heat and infrared radiation, which is used in weapon testing, weapon accessories, offensive equipment, etc., and can solve the problems of vacuum sealing leakage of quartz heaters, burning of tungsten filaments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

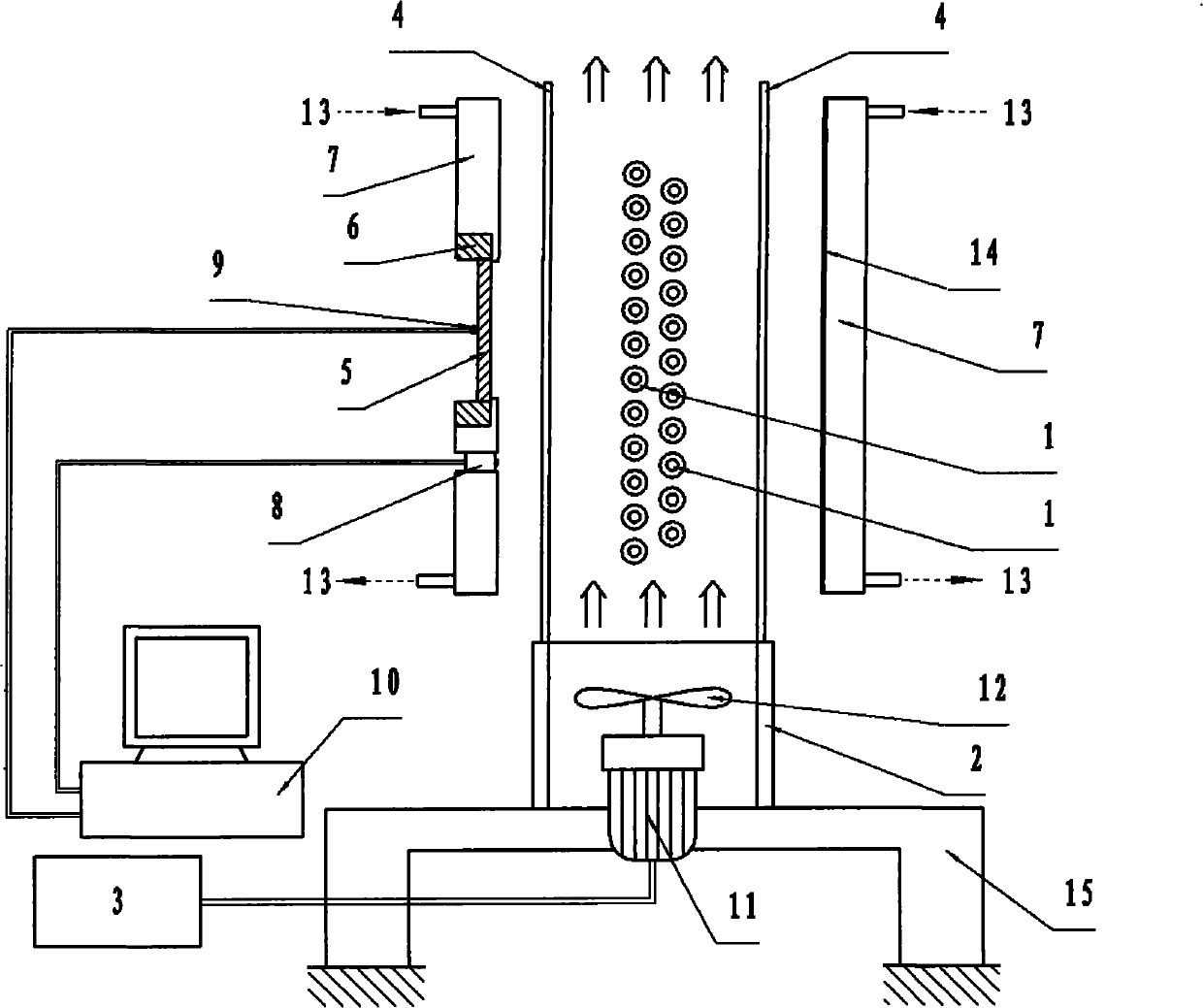

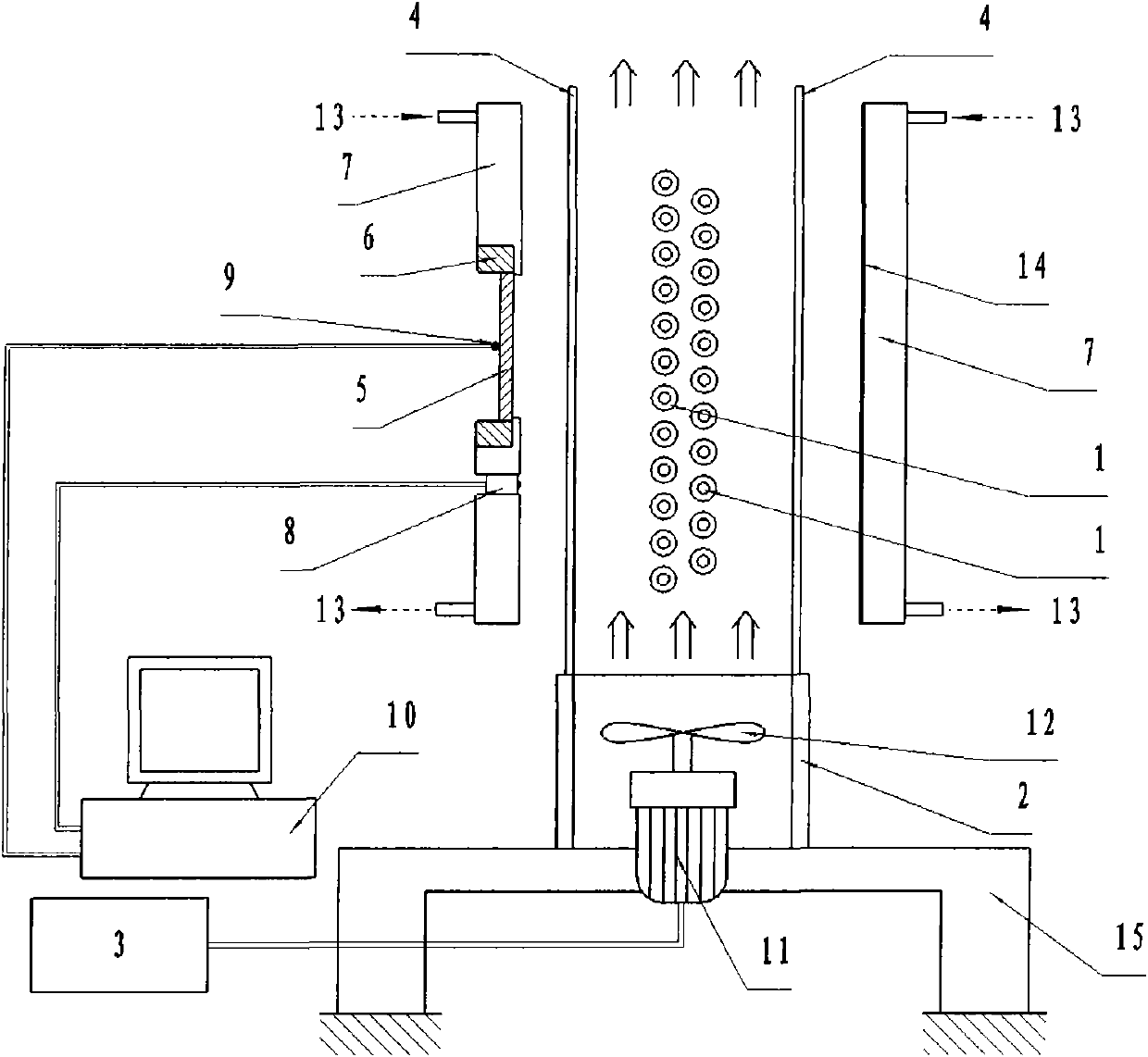

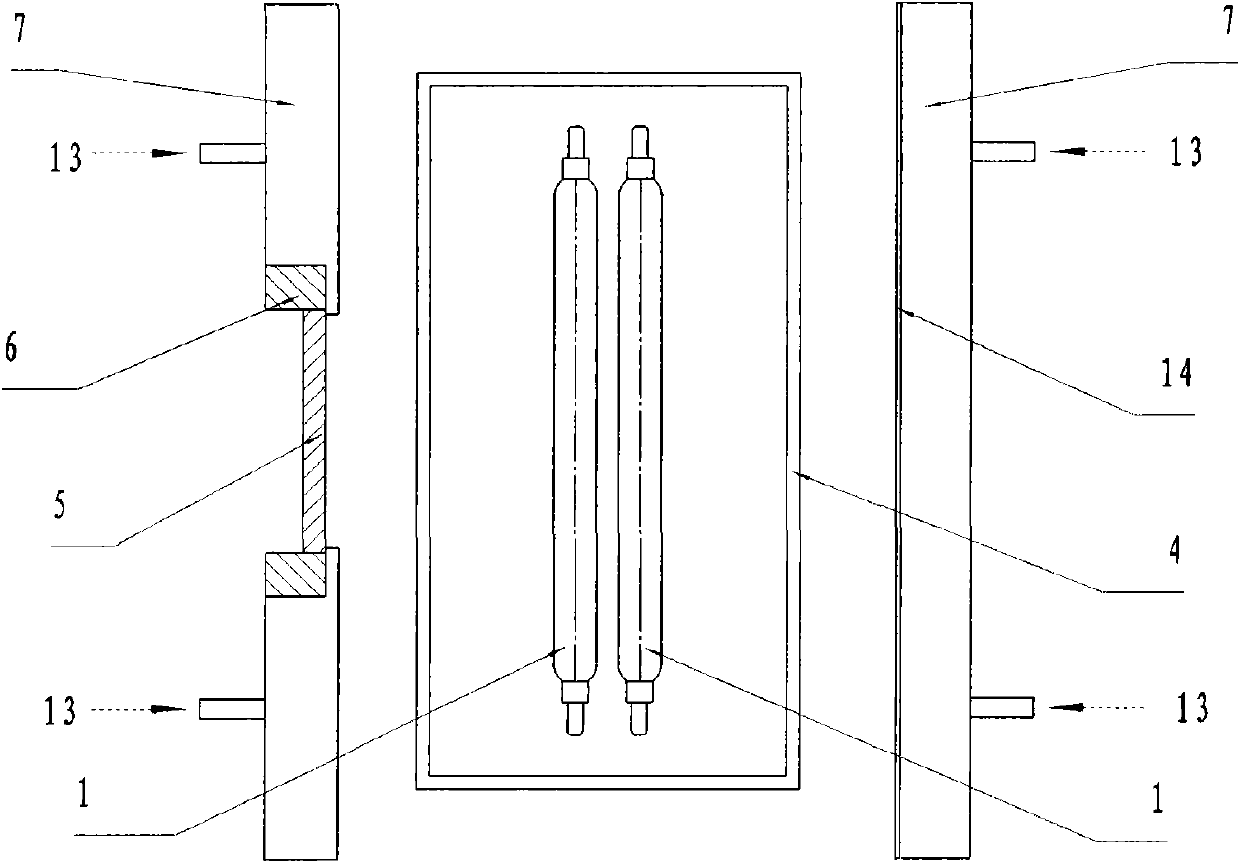

[0022] like figure 1 and figure 2 As shown, the present invention consists of a quartz lamp heating array 1, a fan 2, a frequency converter 3, a quartz glass air flow isolation plate 4, a high temperature radiation test piece 5, an insulating frame 6, a water cooling box 7, a heat flow sensor 8, a temperature sensor 9 and The computer 10 is composed. The quartz lamp heating array 1 is fixedly connected to the electrodes of the quartz lamp by a flat copper bar with good electrical conductivity to form a horizontally arranged densely arranged plane body. The quartz lamp heating array 1 is placed on four transparent quartz glass airflow isolation plates 4 The one-way airflow guides the isolated channel, and the infrared radiation light emitted by the quartz lamp heating array 1 shines on the high-temperature radiation test piece 5 of the missile, simulating the dynamic aerodynamic forces on the surface of the warhead, body or wings of the missile when the missile flies at high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com