Autonomic rotor system for an aircraft

一种飞行器、旋翼的技术,应用在旋翼系统领域,能够解决系统缺少多功能性和可升级性/可扩展性、圆柱形叶片空气动力学叶片外形差距很大等问题,达到提高效率、降低喷管速度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

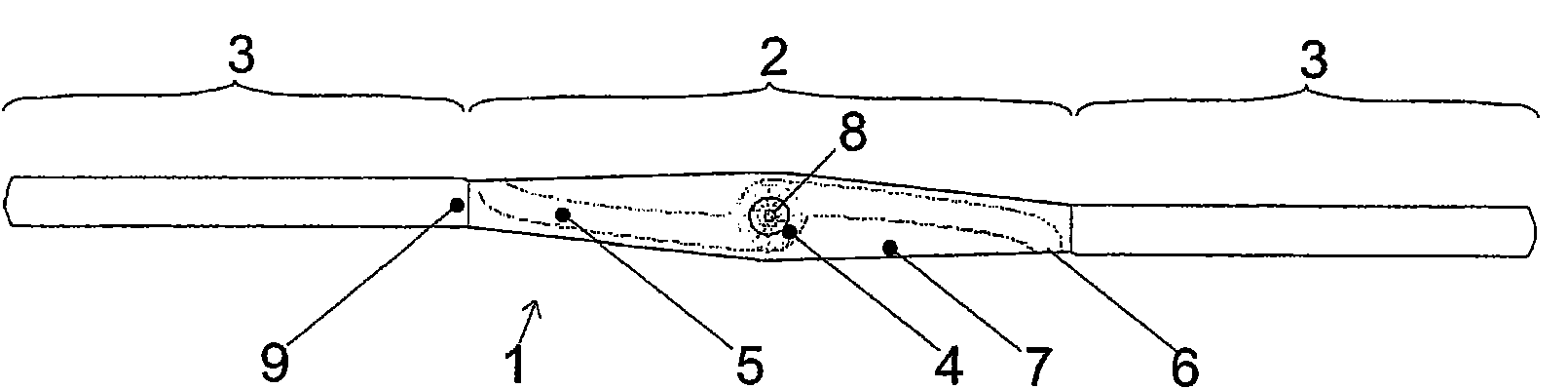

[0070] figure 1 The rotor system seen from above is shown, divided into a drive part 2 and a rotor blade part 3 . The drive part 2 comprises a jet turbine 4 from which a jet flow is conducted via an inner jet duct 5 to a nozzle outlet 6 and thereby directed into a rotary structure 7 . The nozzle outlet 6 is designed such that the jet stream from the nozzle outlet 6 is perpendicular to the longitudinal axis of the rotating structure 7 and acts in the plane of rotation to provide maximum effect. The rotor 1 of the system comprises a rotating structure 7 and rotor blades 3 fixed to the rotating structure 7 by their proximal ends 9 , as opposed to their distal ends, and rotating together with the rotating structure 7 about an axis of rotation 8 .

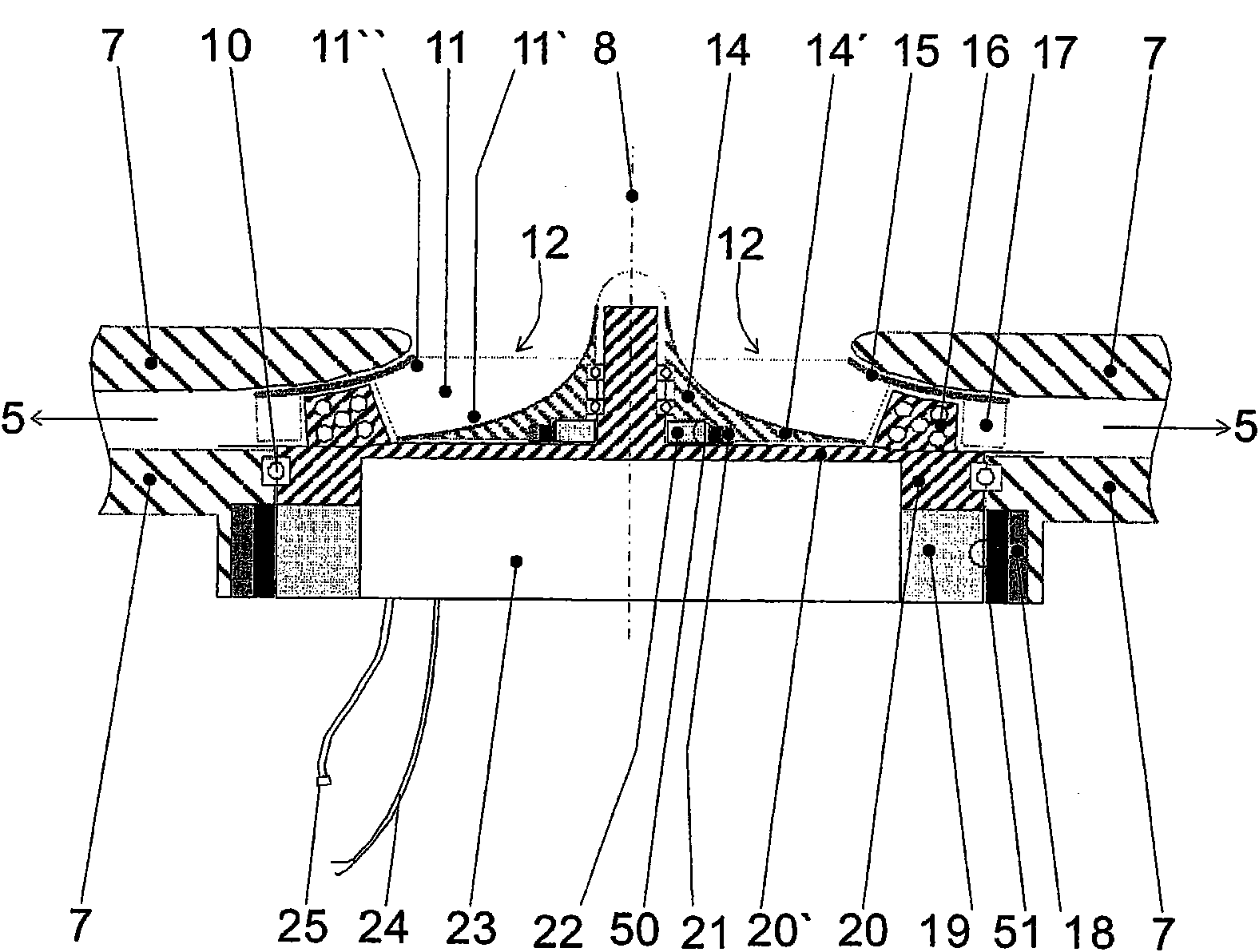

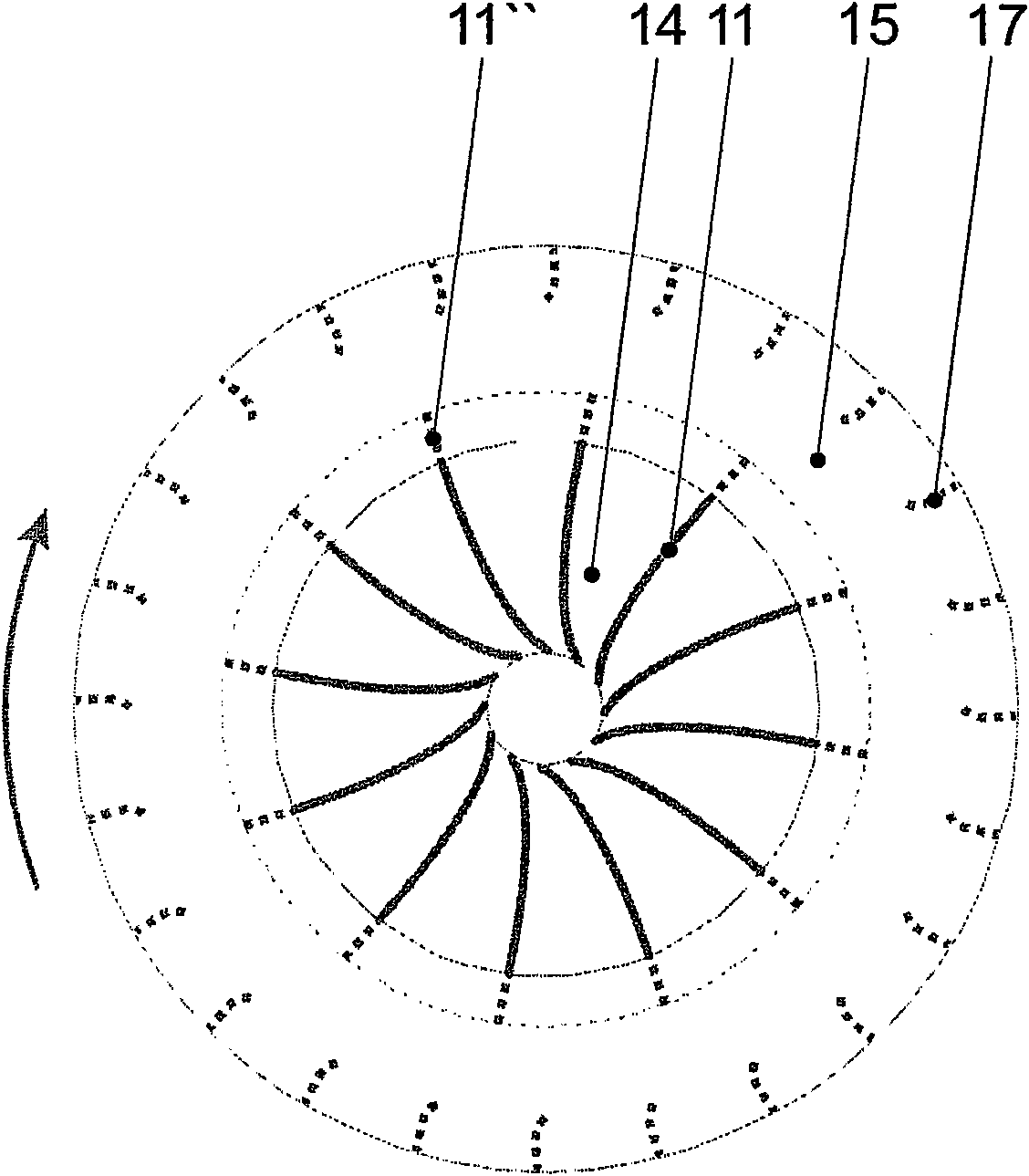

[0071] figure 2 A sectional view of a radial jet turbine 4 is shown. The drive part 2 of the rotor system mainly includes three mechanical structures, which are:

[0072] - a support structure 20 connected to the aircraft;

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com