Equestrian surfacing materials

一种铺面、重量的技术,应用在赛马、赛马场、薄料处理等方向,能够解决材料稳定性问题等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

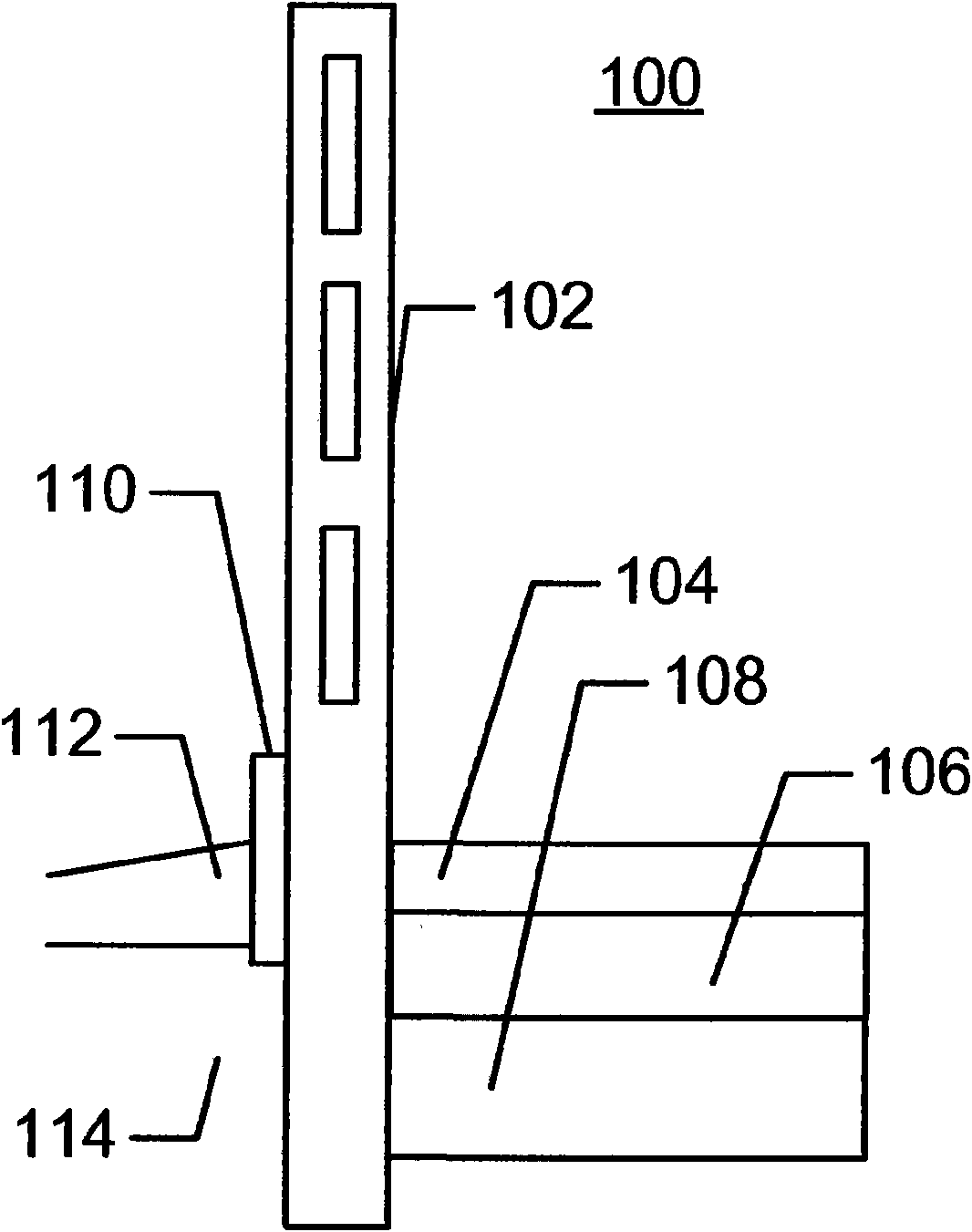

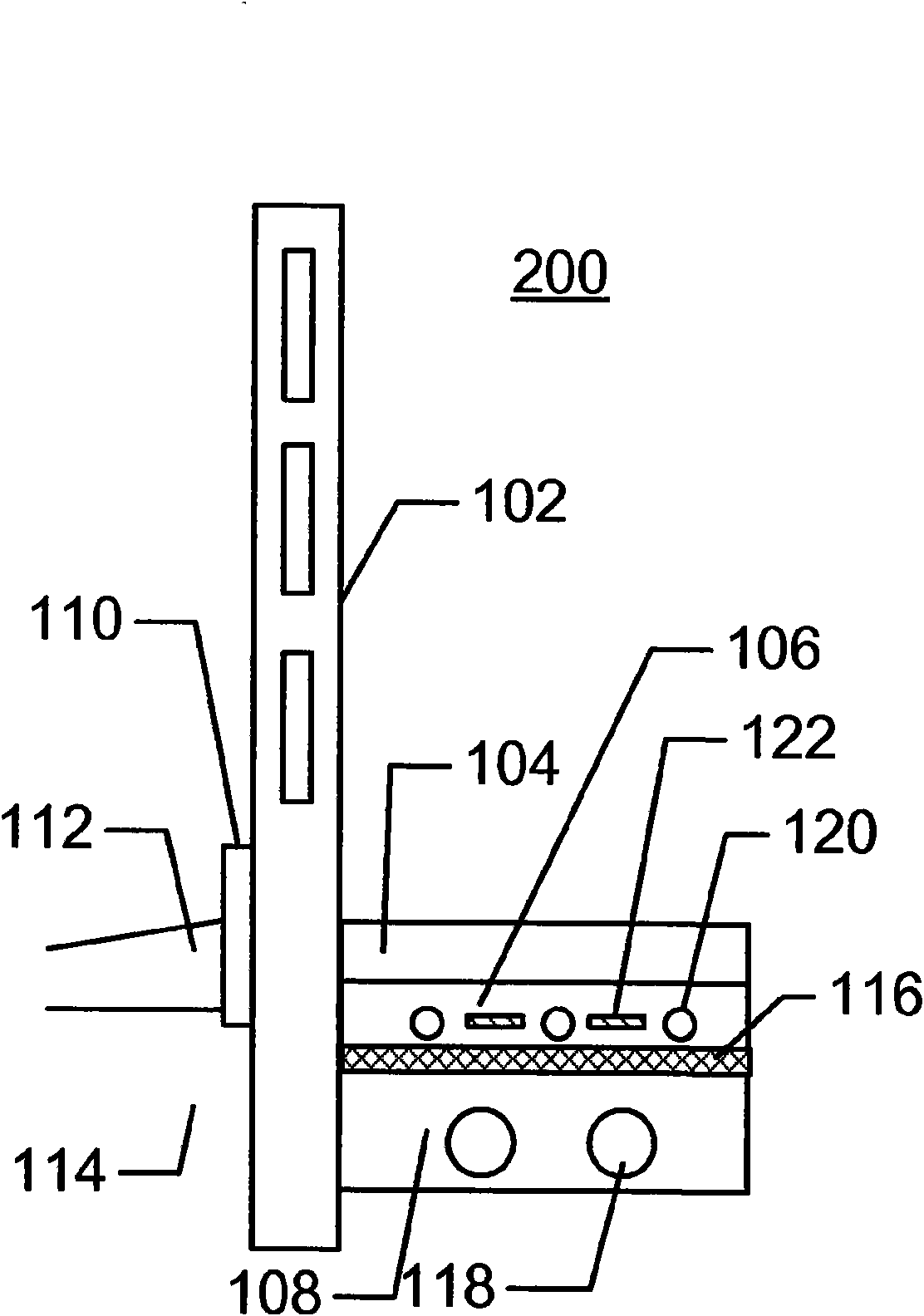

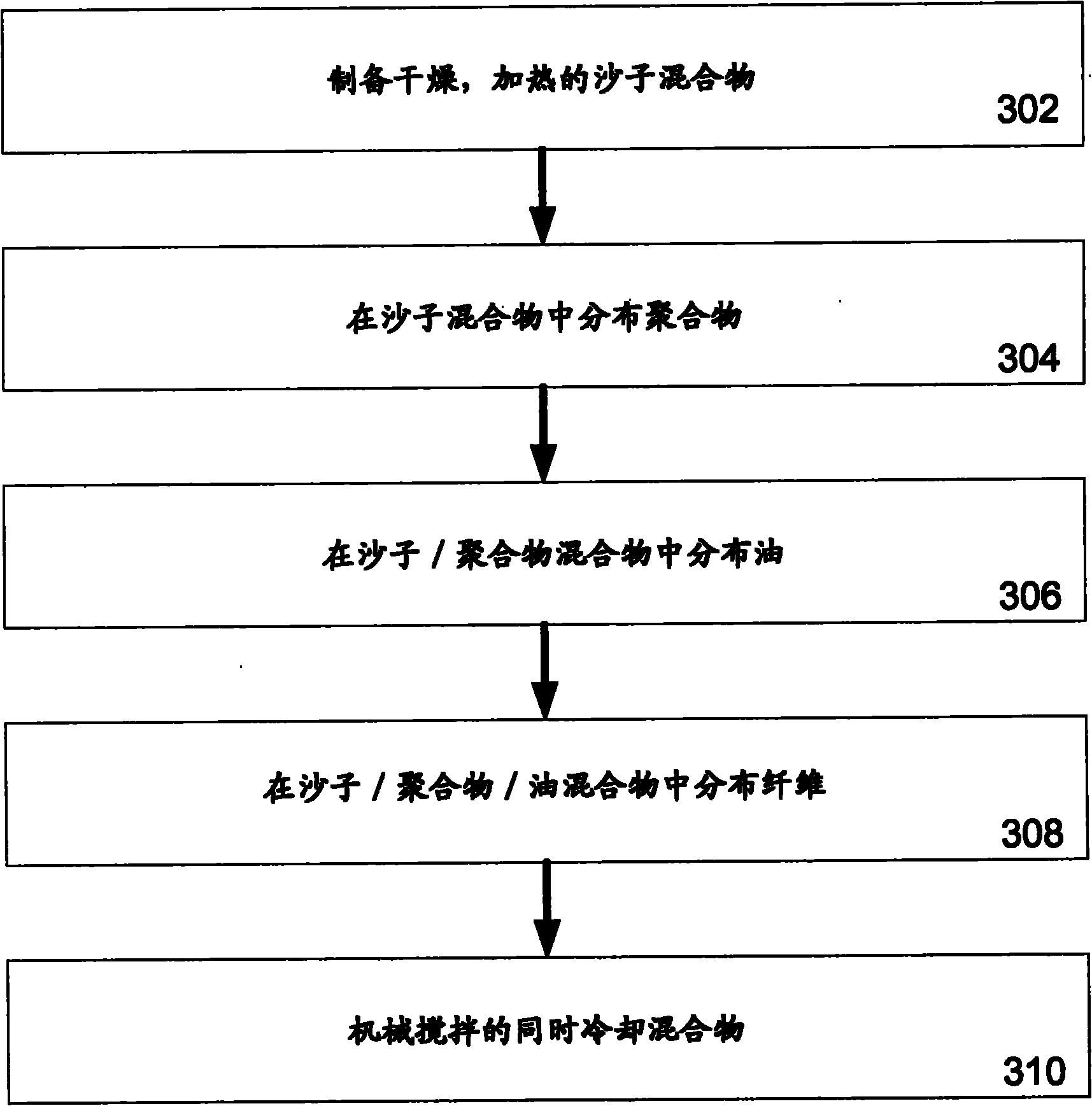

Image

Examples

Embodiment 1

[0044] A first example surfacing composition was prepared using the combination of components shown in Table 5 below.

[0045] Element

weight percentage

sand

90

polymer

5.0

Oil

3.0

fiber

2.0

[0046] table 5

[0047] The sand mixture used in the preparation of Example 1 was typical ASTM Specification C33 Concrete Sand with a sub-angular particle shape and graded distribution shown in Table 6 below.

[0048] Sieve size

pass%

3 / 8

100

4

98

8

87

16

70

30

40

50

10

100

3

200

1.7

[0049] Table 6

[0050] The polymer used is polypropylene, specifically MARLEX TM AGM 110, available from Phillips Sumika Polypropylene Company, The Woodlands, Texas, USA. The oil is a paraffinic paraffinic oil, specifically DRAKEOL TM350, which was purchased from Penreco, Dickinson, Texas, USA. The fibers used...

Embodiment 2

[0054] A second example surfacing composition was prepared with the combination of components shown in Table 7 below.

[0055] Element

weight percentage

sand

93.5

polymer

3.0

Oil

1.5

fiber

2.0

[0056] Table 7

[0057] The sand mixture used in the preparation of Example 2 was typical ASTM specification C33 concrete sand with a sub-angular particle shape and the graded distribution shown in Table 6 above.

[0058] The polymers used are polyalphaolefins, especially VESTOPLAST TM 408, which was purchased from Evonik Degussa Corporation, 379 Interpace Parkway, Parsippany, NJ, USA. The oil is a paraffinic paraffinic oil, specifically DRAKEOL TM 21, which was purchased from Penreco, Dickinson, Texas, USA. The fiber is the polypropylene fiber used in Example 1.

[0059] The sand is prepared by heating in a bitumen drying drum to achieve a sand temperature of about 120 to about 130°C and a moisture content of le...

Embodiment 3

[0062] A first example surfacing composition was prepared with the combination of components shown in Table 8 below.

[0063] Element

weight percentage

sand

94.0

polymer

4.0

fiber

2.0

[0064] Table 8

[0065] The sand mixture used in the preparation of Example 3 was typical ASTM specification C33 concrete sand with a sub-angular particle shape and the graded distribution shown in Table 6 above. The polymer used was an amorphous polyalphaolefin (APAO), specifically Vestoplast 508, commercially available from Evonik Degussa Corporation, 379 Interpace Parkway, PO Box 677, Parsippany, NJ 07054. The fiber used was 2 denier polyester having a fiber length of about 0.6 cm (about 1 / 4 inch), which was purchased from William Barnet & Son, 1300 Hayne Street, Arcadia, SC 29320.

[0066] As shown in the examples above, the sand was prepared by heating in a bitumen drying drum to obtain a sand temperature of 120-150°C and a moisture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com