Tile rebate cutting apparatus

一种切割设备、凹榫的技术,应用在贴砖凹榫切割设备领域,能够解决损坏贴砖、难切口精确定位、浪费等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

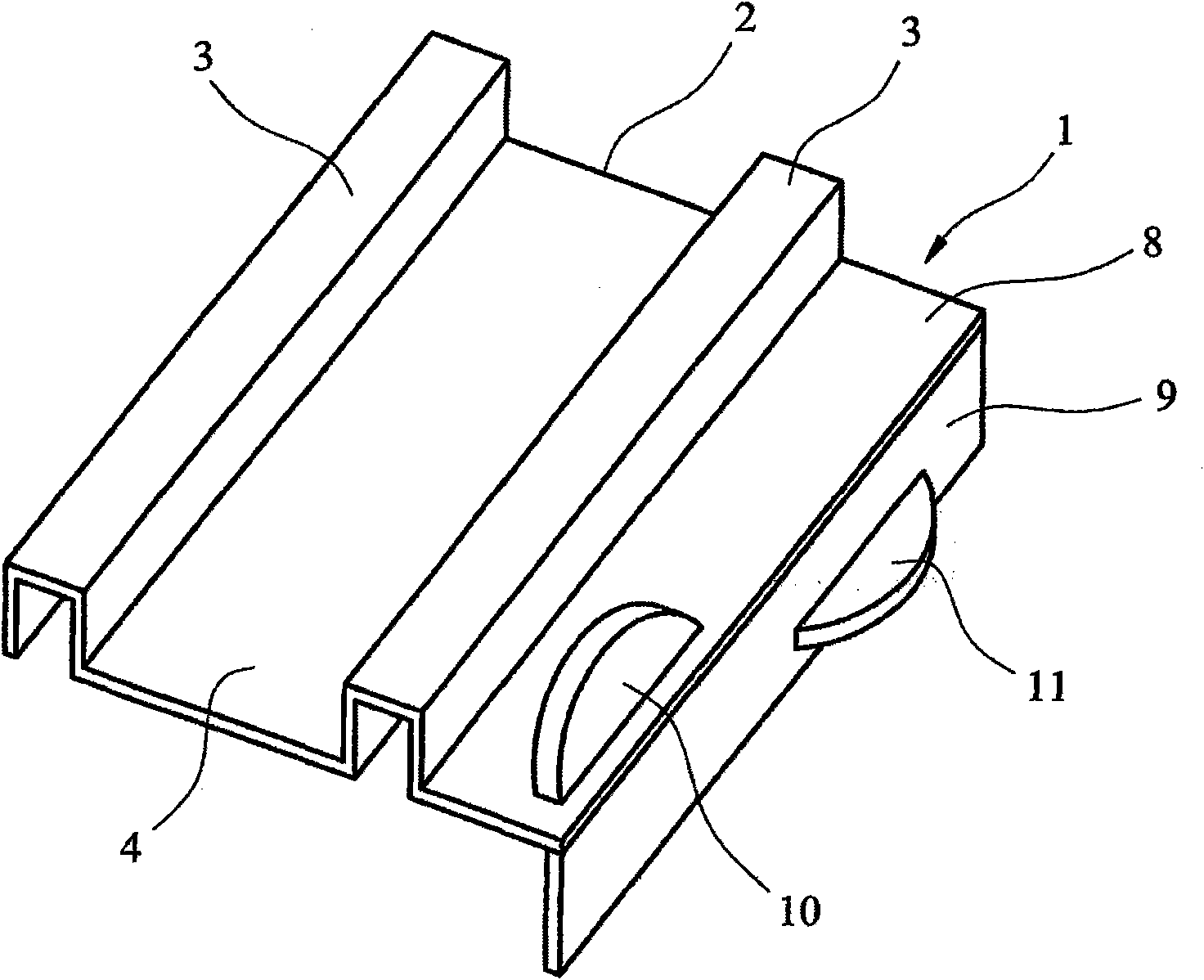

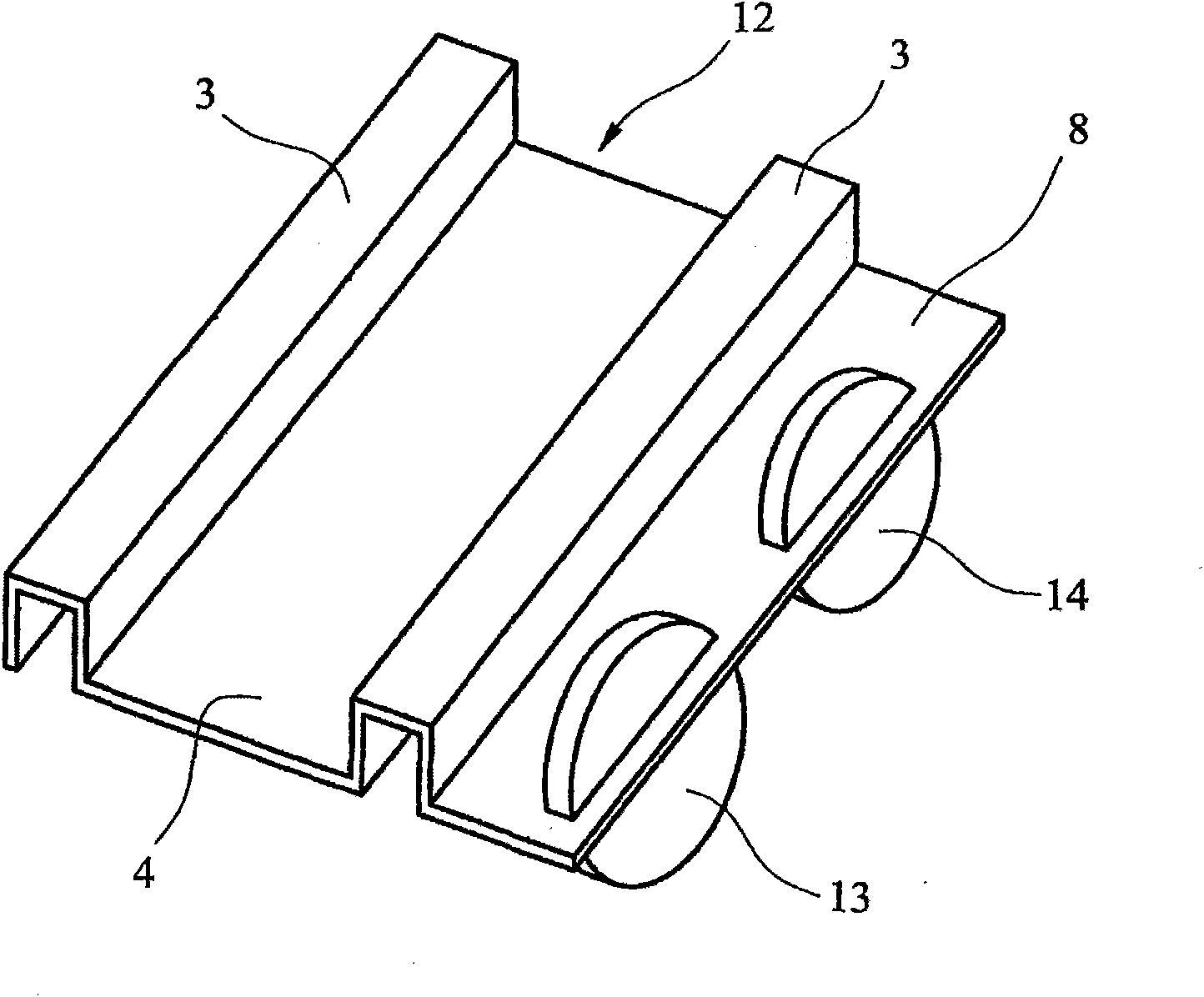

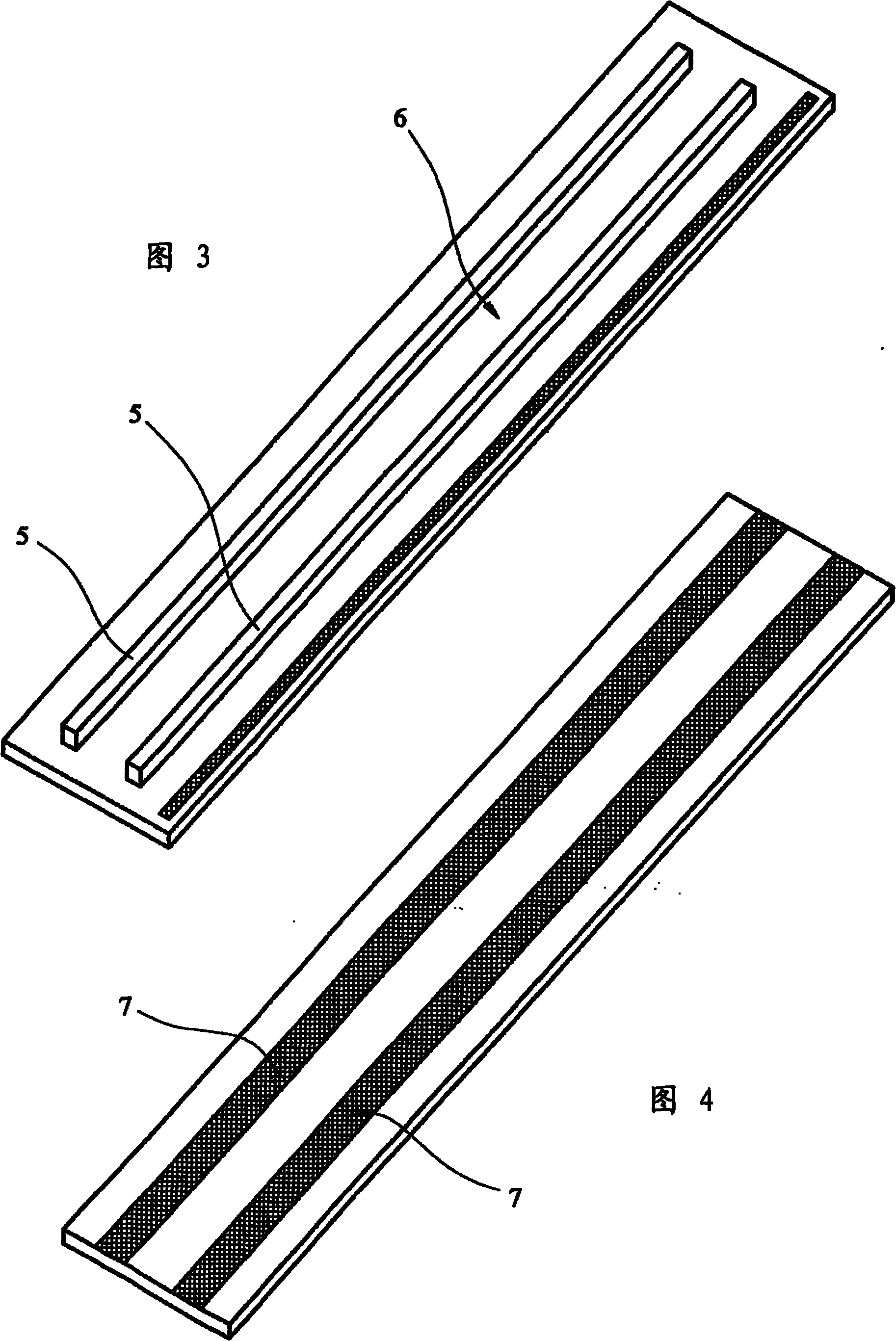

[0027] Referring now to the accompanying drawings Figures 1 to 4 ,exist figure 1 A groove cutting tool 1 is shown in , which is used to cut a groove along one edge of such ceiling tiles, usually formed from foam or expanded plastic material. Said cutting tool 1 consists of a body 2, generally formed of extruded aluminium material, having two downwardly open channels 3 arranged in parallel spaced relation, separated by a base element 4 of the body . The two channels 3 are adapted to engage with two guide rails 5 positioned in parallel spaced relation to the guide member 6 (see image 3 ), the guide member may also be formed from an aluminum extrusion. On its underside, the guide member 6 has a strip 7 of material, such as rubber glued or embedded in the guide member, in order to provide the guide member 6 with a non-slip underside. Many other forms of non-slip surfaces are available.

[0028] Especially as figure 1 As shown, the groove cutting tool 1 has another base ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com