Ribbed superposed prestressed reinforced concrete precast slab

A technology of reinforced concrete and prestressed steel bars, applied in the direction of floors, building components, buildings, etc., can solve the problems of difficult demoulding, increasing construction time and construction difficulty, and complicated procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

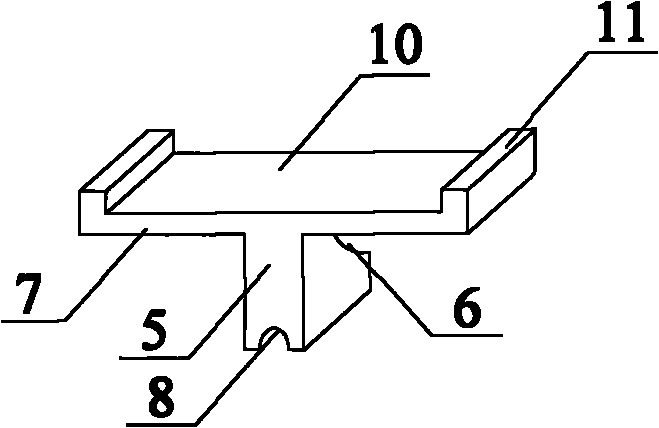

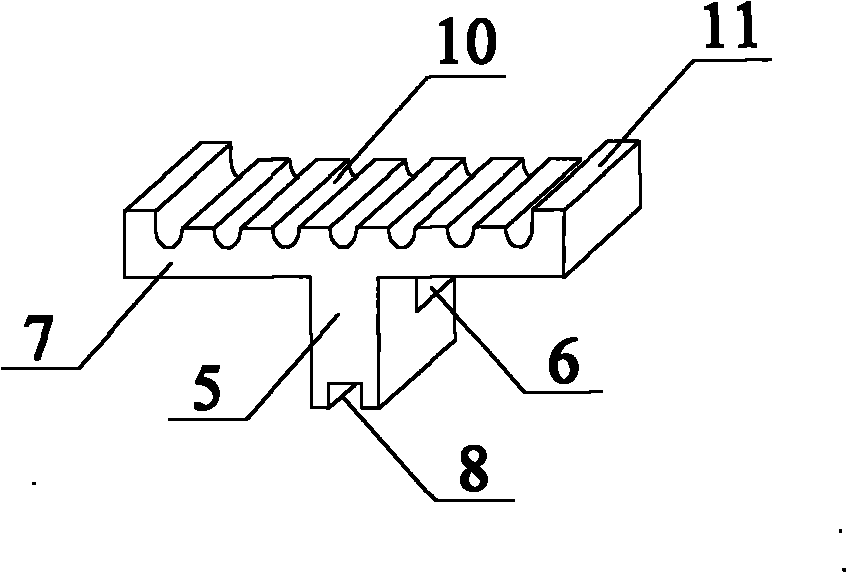

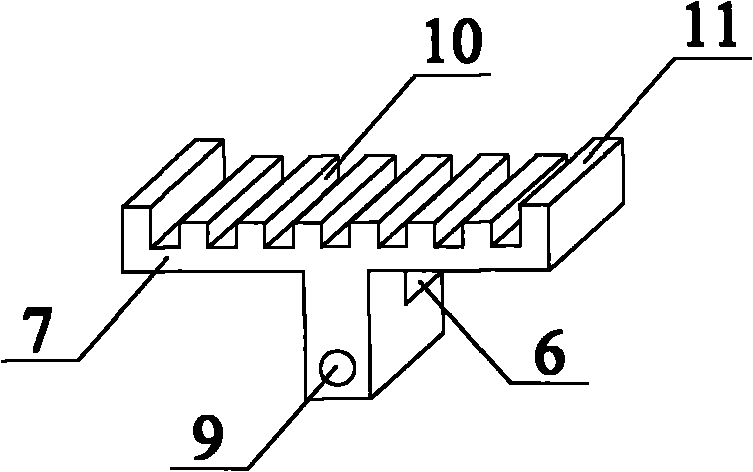

[0028] As shown in the accompanying drawings, the present invention is a ribbed laminated prestressed reinforced concrete prefabricated slab, which includes a prefabricated block 1, a hole 2, a post-cast concrete laminated layer 3, and steel bars 4. It is characterized in that there are side projections 11 at the bottom of the bottom plate 7 of the prefabricated block 1 . figure 1 5 is the longitudinal rib, 6 is the notch of the longitudinal rib, 7 is the bottom plate, 8 is the groove of the longitudinal rib, 9 is the hole of the longitudinal rib, 10 is the longitudinal groove at the bottom of the bottom plate, and 11 is the protrusion on the bottom edge of the bottom plate . In other drawings, those with the same numbers have the same descriptions. figure 1 As shown, the notch 6 of the longitudinal rib is arc-shaped, and the section form of the groove 8 of the longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com