Constructing process of outer wall cladding

A construction technology and technology of cladding panels, which are applied in building maintenance, covering/lining, construction, etc., can solve problems affecting the safety of cladding panels, large safety of cladding panels, hidden dangers, etc., and achieve good connection effect, ensure safety, construction low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

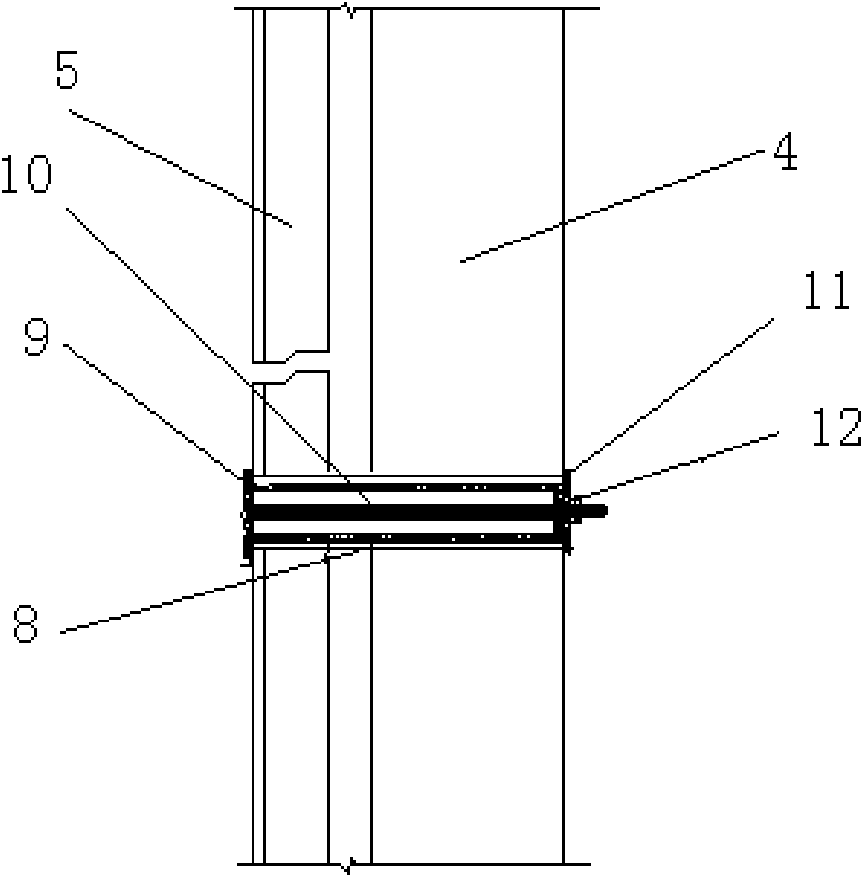

[0015] The present invention will be further described below in conjunction with accompanying drawing:

[0016] As shown in the accompanying drawings, a construction process for external wall hanging panels is characterized in that the steps are as follows:

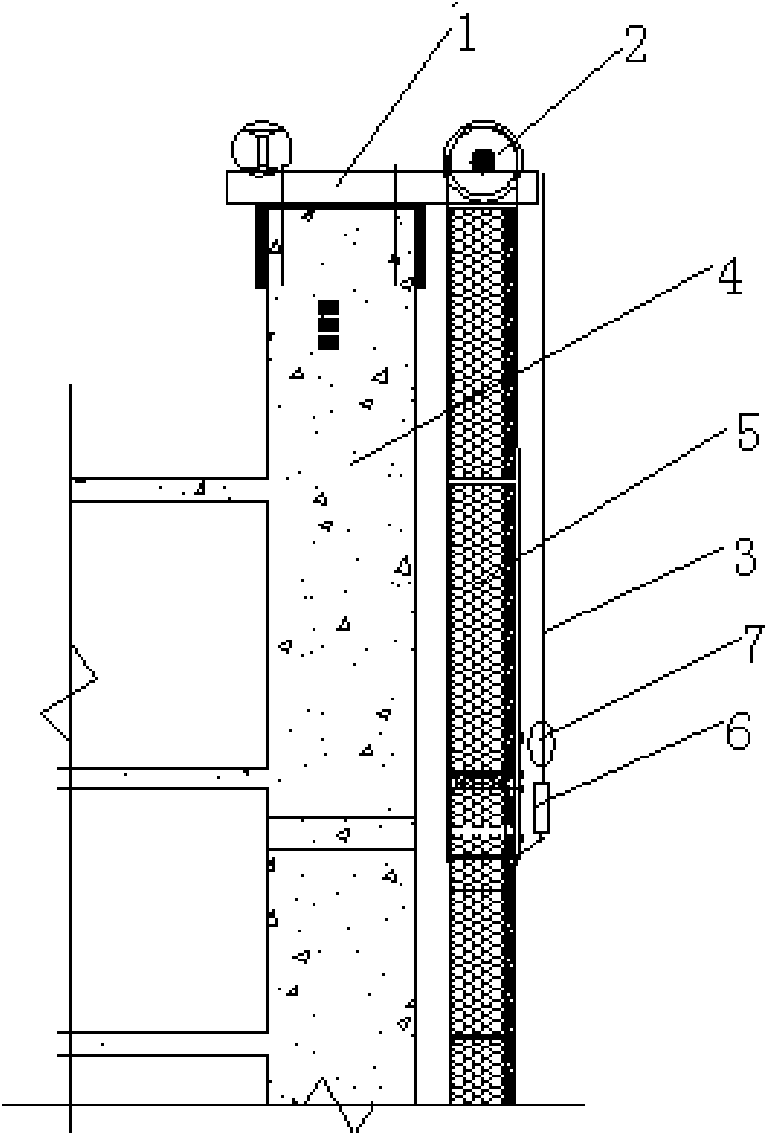

[0017] The first step is to fix the steel beam 1 on the roof and operate the hanging basket, wherein the steel beam 1 protrudes at least 300mm from the wall surface to connect the pulley for construction work,

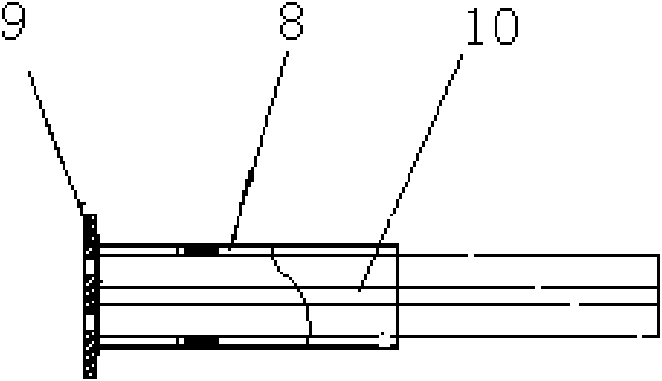

[0018] The second step is to pass the pulley 2 through the connecting shaft and weld the connecting shaft and the steel beam 1 to fix it. The steel wire rope 3 passes through the pulley 2, and one end is put between the surface of the wall 4 and the external hanging plate 5 and passes through the external hanging plate 5. The position is generally at the bottom of the external hanging plate 5, and a lifting hole can also be drilled on the external hanging plate 5. The steel wire rope 3 inside the external hanging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com