Detonator filling mould and preparation method thereof

A manufacturing method and detonator technology, which are applied to weapon accessories, fuzes, ammunition and other directions, can solve the problems of low work efficiency, increase the complexity of the production line, and difficulty in automatic production, and achieve the advantages of labor-saving and convenient use, convenient removal of detonators, and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

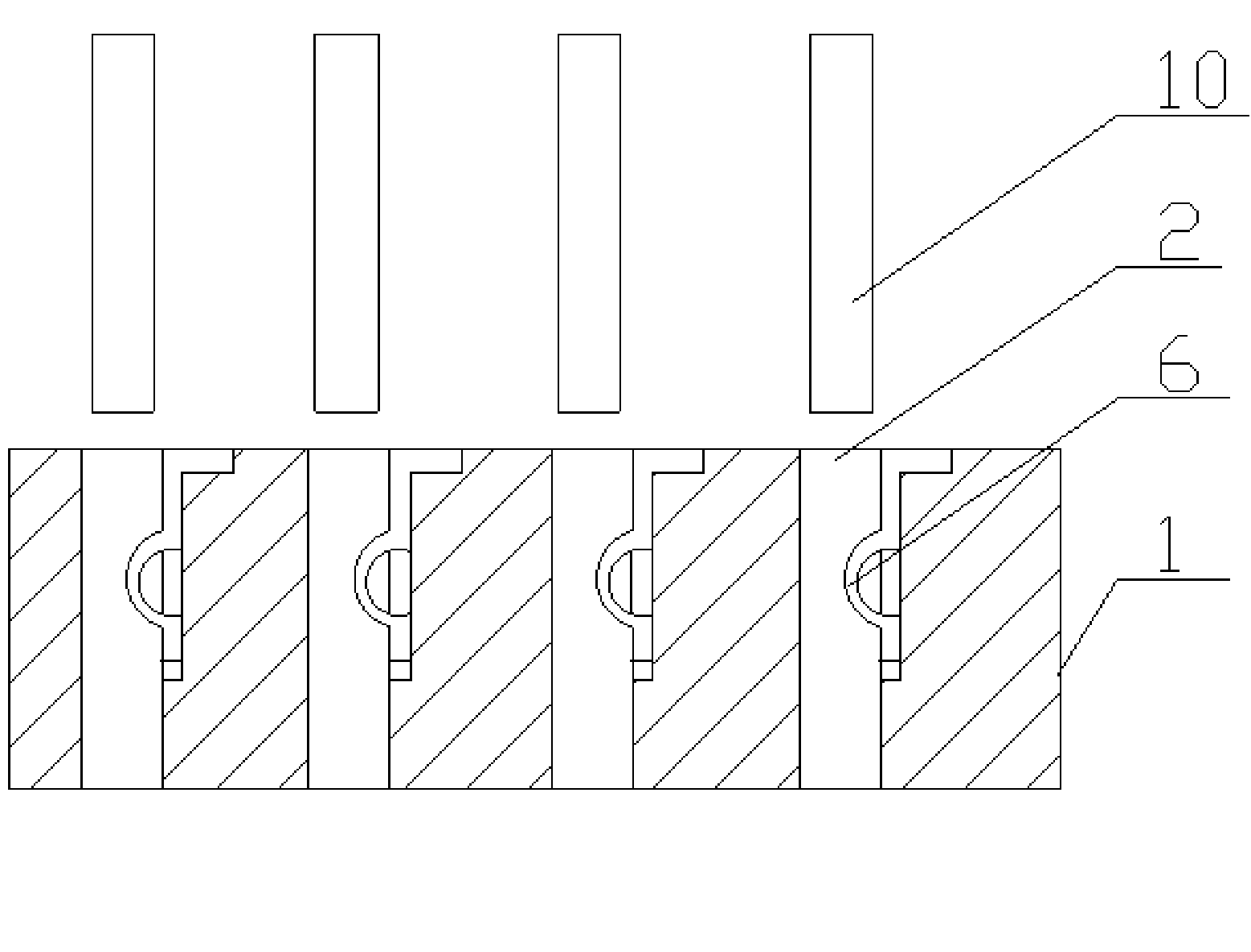

[0017] Embodiment 2 of the present invention: as figure 2 As shown, the quantity of the detonator placement holes 2 on the template 1 is determined according to the scale of production and needs in the traditional way during production, and the detonator placement holes 2 on the template 1 are made as through holes, and then placed in each detonator of the template 1 A piece of elastic sheet 6 as an elastic clamping device is fixed in the hole 2; when fixing the elastic sheet 6, it can be fixed in the detonator placement hole 2 of the template 1 by bonding or screwing, and the elastic sheet 6 can be made of rubber, It can be made of plastic or elastic copper sheet.

Embodiment 3

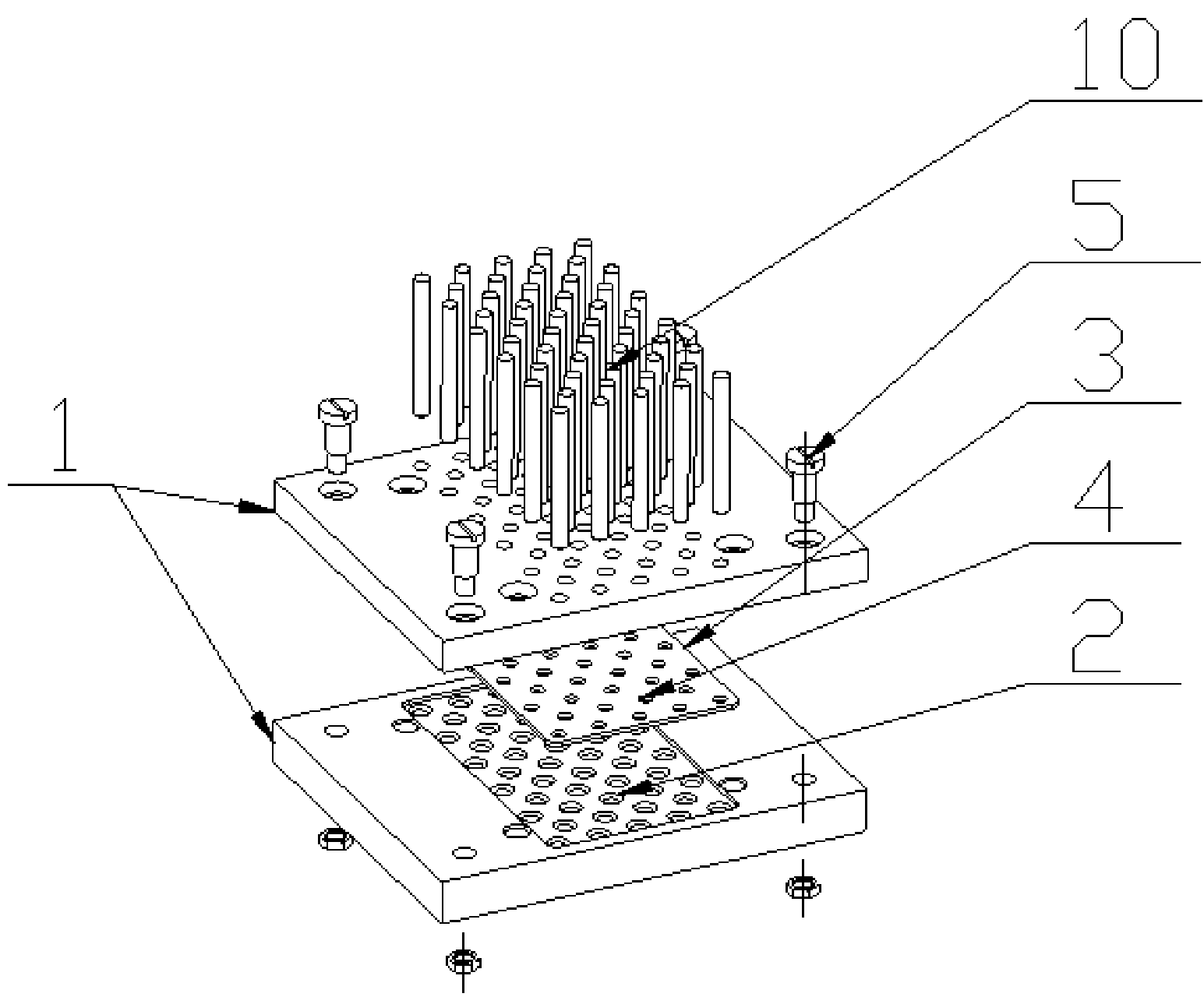

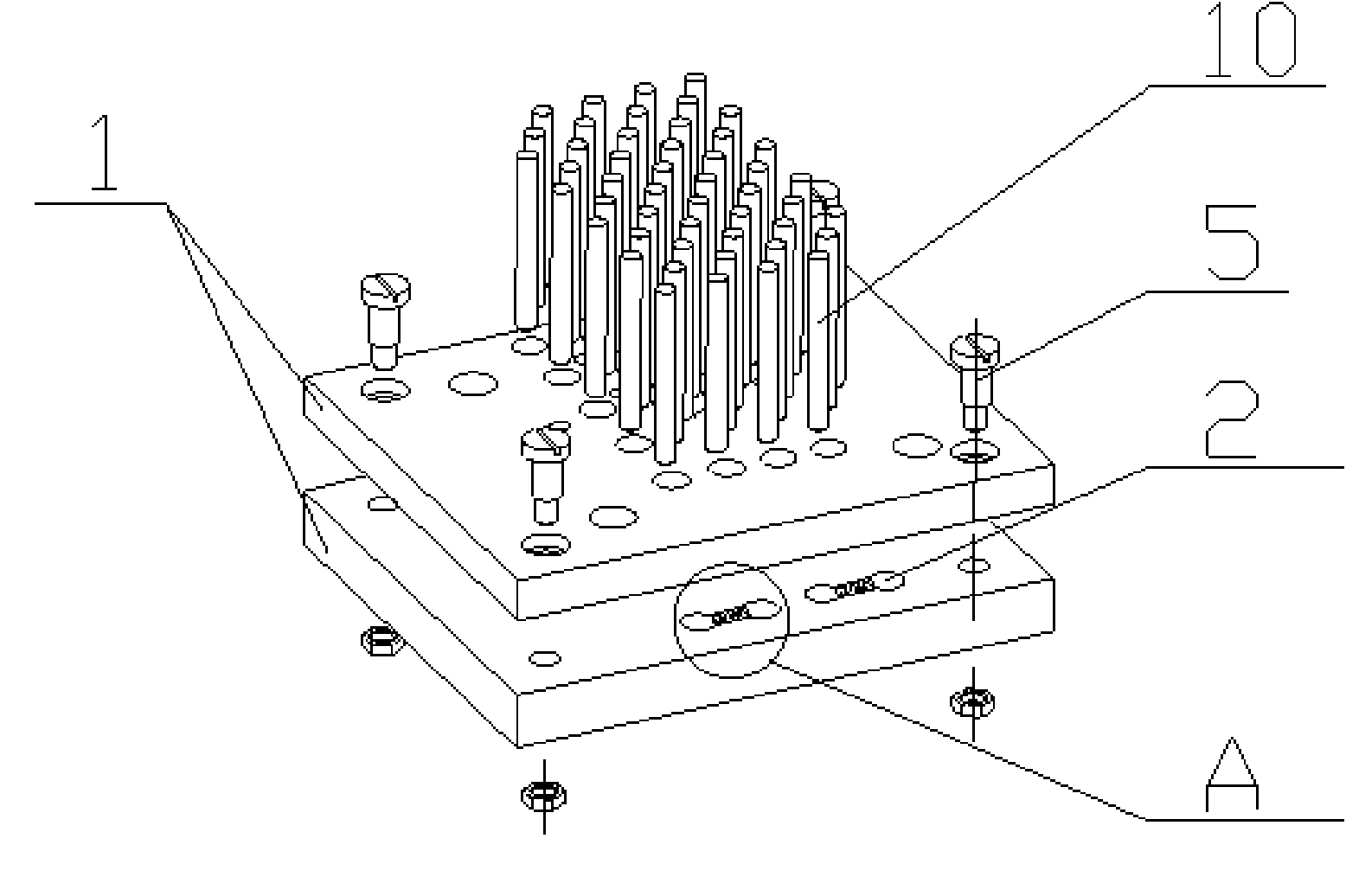

[0018] Embodiment 3 of the present invention: as image 3 As shown, according to the scale of production and the need to determine the number of detonator placement holes 2 on the template 1 during production, the detonator placement holes 2 on the template 1 are all made as through holes, and the template 1 is made by two A flat plate with the same number and the same positions of detonator placement holes 2 is formed, and then on the surface where the two templates 1 are bonded, a half is made on the side of each detonator placement hole 2 by mechanical processing. Circular installation groove 9, spring (7) and ball (8) as elastic fastening device are installed in installation groove 9, and the part spherical surface of each ball 8 protrudes from the inner wall surface of detonator placement hole 2, and then The two formworks 1 are pasted together and connected as a whole by bolts 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com