Printing method and device of heat-sensitive printer

A thermal printer, thermal paper technology, applied in the direction of digital output to printing unit, printing, etc., can solve the problem of thermal printer printing speed, the fastest printing speed is very different, and save time and improve printing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

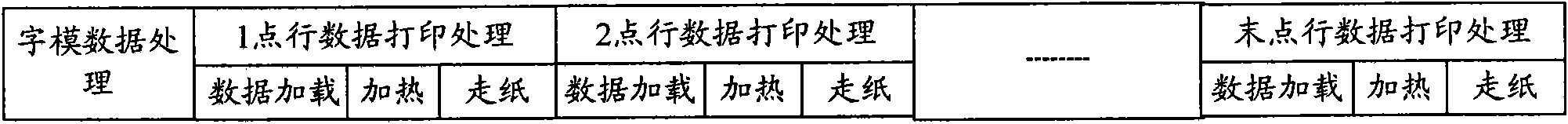

[0036]Embodiment 1. In this embodiment, the hardware structure of the thermal printer does not need to be modified. The data processing is data loading, that is, during the printing process of the current dot row data, the next dot row data is loaded. see image 3 , the printing process of thermal printer includes:

[0037] On the thermal paper, the current dot line data to be printed in the thermal printer is printed. During the printing process, when the current dot matrix to be printed is When the data has unprinted next line of data, load the next line of data into the data register and latch it. After the time used for the printing process is reached, it is necessary to complete the printing of a line of data, which shows that it has been printed on the thermal sensor. Current point row data on paper.

[0038] It can be seen that in the embodiment of the present invention, when the printing processing is heating processing, it can be judged whether the current dot matr...

Embodiment 2

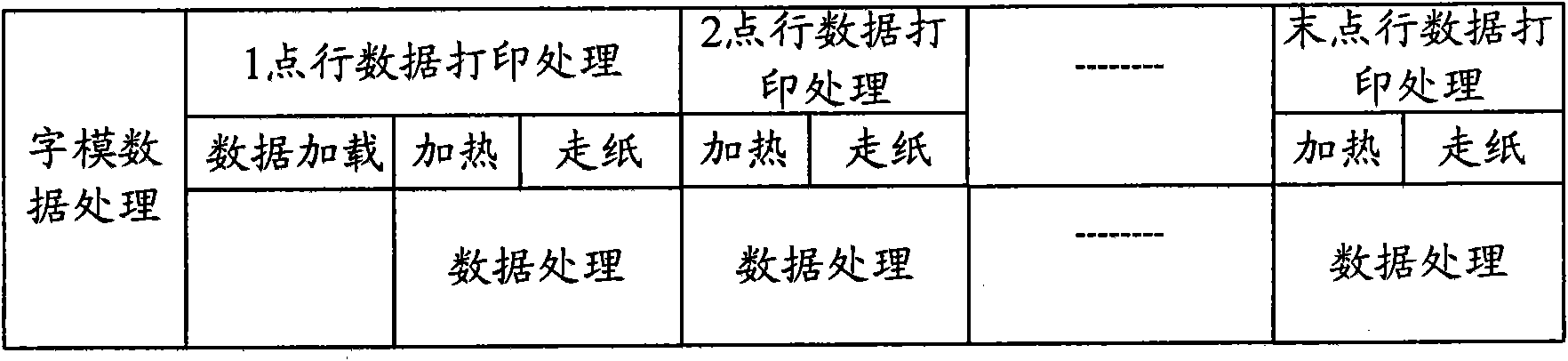

[0048] Embodiment 2. In this embodiment, the data processing is font conversion processing, that is, during the printing process of the current dot row data, the font conversion processing of the next dot matrix data is performed. Moreover, there are two or more buffer areas in the storage area of the thermal printer, and each buffer area can store dot matrix data corresponding to all characters to be printed that the thermal printer can process at one time. In this way, when printing the current dot matrix data to be printed stored in the first buffer area, the time spent in the printing process can be used to convert the newly received characters to be printed, and store the converted dot matrix data in the first buffer. in the second cache. See the specific process Figure 4 , the printing process of thermal printer includes:

[0049] On the thermal paper, print the current dot line data that is currently to be printed in the thermal printer and that has been latched. D...

Embodiment 3

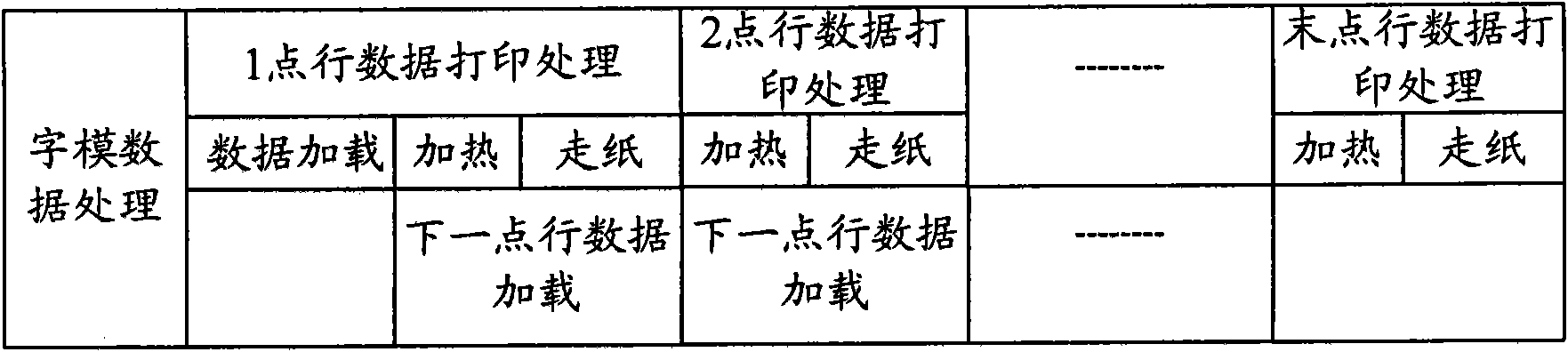

[0065] Embodiment 3. In this embodiment, data processing includes: data loading and font conversion processing, that is, in the process of printing the current dot row data, the loading of the next dot row data and the font conversion of the dot matrix data under the row are carried out deal with. Moreover, there are two or more buffer areas in the storage area of the thermal printer, and each buffer area can store dot matrix data corresponding to all characters to be printed that the thermal printer can process at one time. Wherein, the current to-be-printed dot matrix data stored in the first buffer area. See the specific process Figure 5 , the printing process of thermal printer includes:

[0066] On the thermal paper, print the current dot row data that is currently to be printed in the thermal printer, and during the printing process, when the first buffer area of the thermal printer is currently to be printed When the dot matrix data has unprinted next dot row da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com