Fabrication method of terminal belts as well as terminal belts and terminals therefrom

A manufacturing method and a terminal strip technology are applied to terminals. , in the field of terminal strips, it can solve problems such as multiple burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

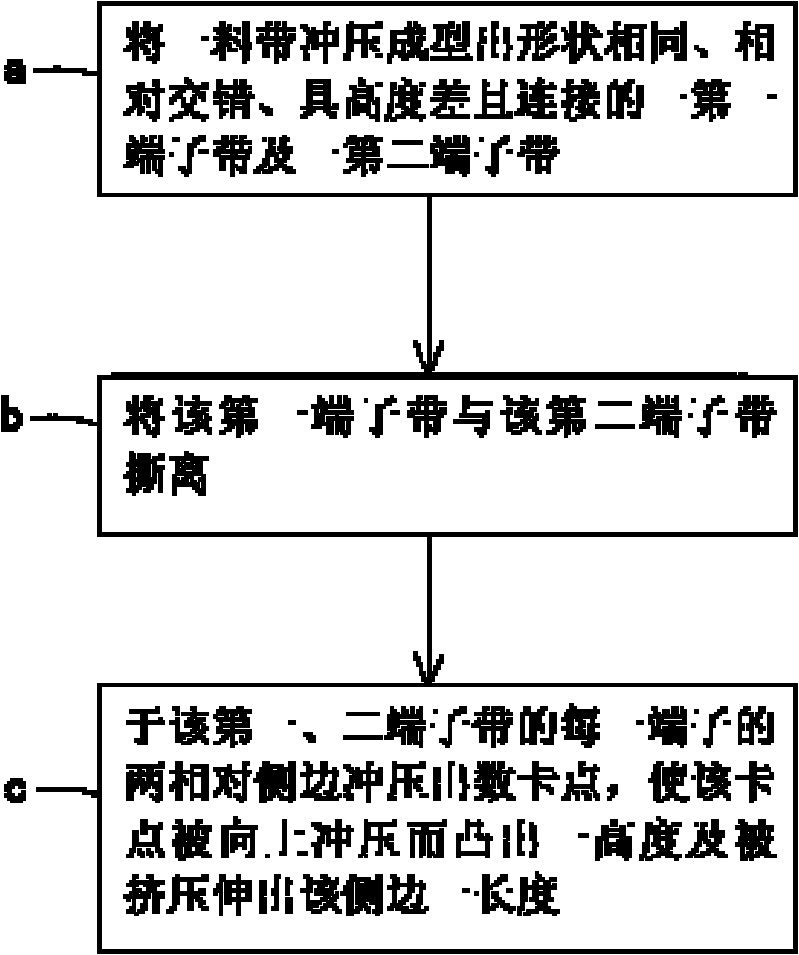

[0035] see figure 1 As shown, it is pointed out that the manufacturing method of the terminal strip of the present invention includes:

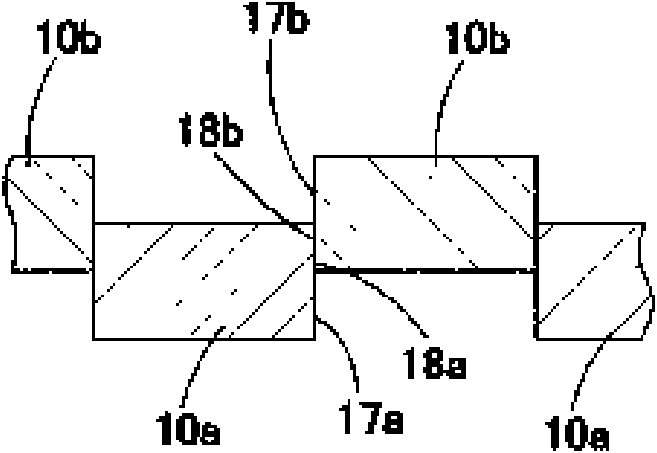

[0036] (a) Stamping a material strip to form a first terminal strip and a second terminal strip that are identical in shape, relatively staggered, have a height difference, and are connected, such as figure 2 and image 3 shown.

[0037] (b) tearing off the first terminal strip from the second terminal strip; and

[0038] (c) Punch out several card points on the two opposite sides of each terminal of the first and second terminal strips, so that the card points are punched upward to protrude a height and pushed outward to protrude from the Side-length. When stamping the card points, these terminals are also bent and formed at the same time to make a terminal with a finished product, such as Figure 5 shown.

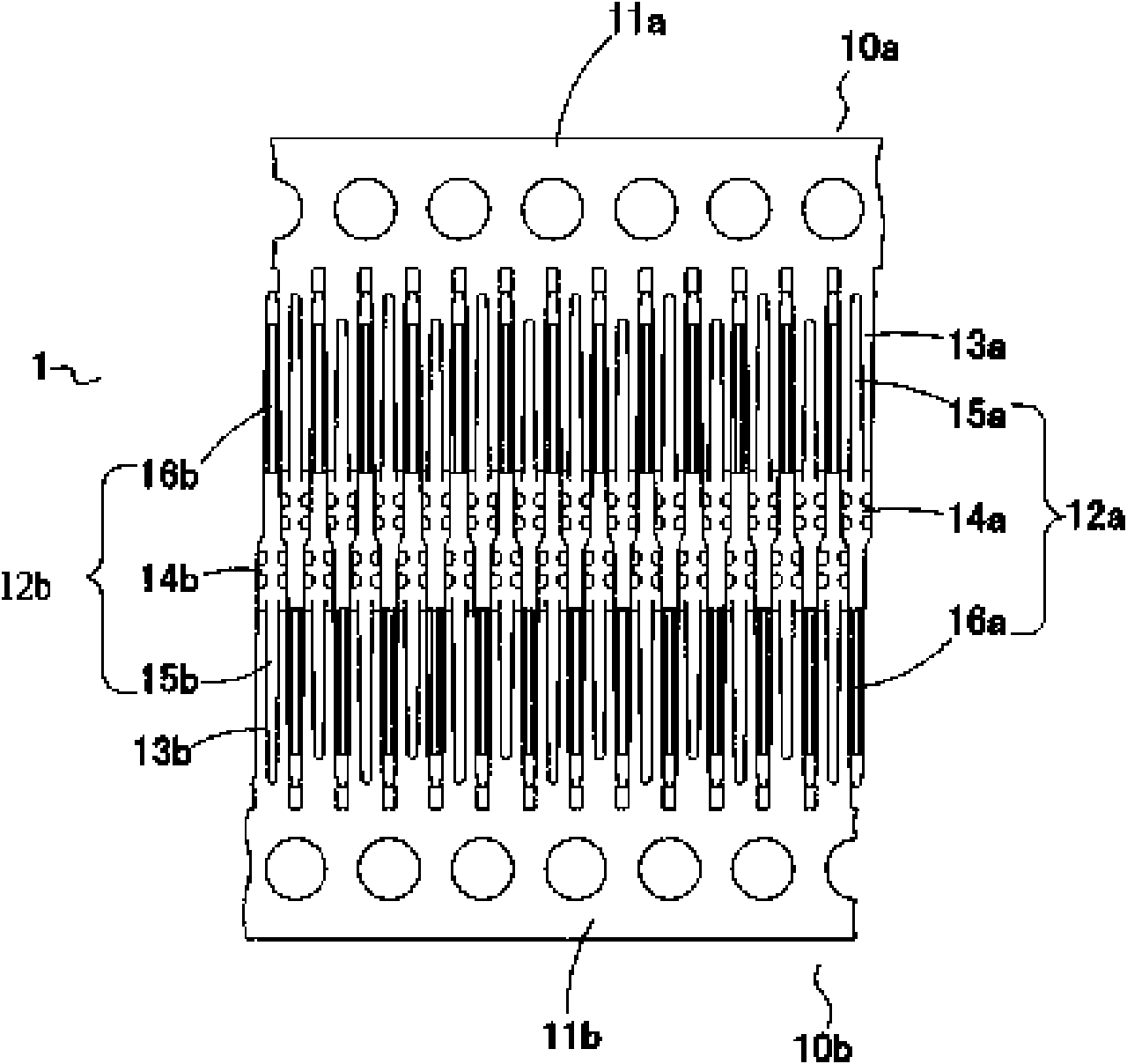

[0039] see figure 2 As shown, it is a schematic plan view of the first terminal strip 10a and the second terminal strip 10b f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com