Marten skinning machine

A technology of mink fur machine and sliding bar, which is applied in the direction of peeling tools, etc., can solve the problems of low peeling efficiency, damaged skin, and failure to realize value, and achieve the effect of high work efficiency, simple structure, and the integrity of peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

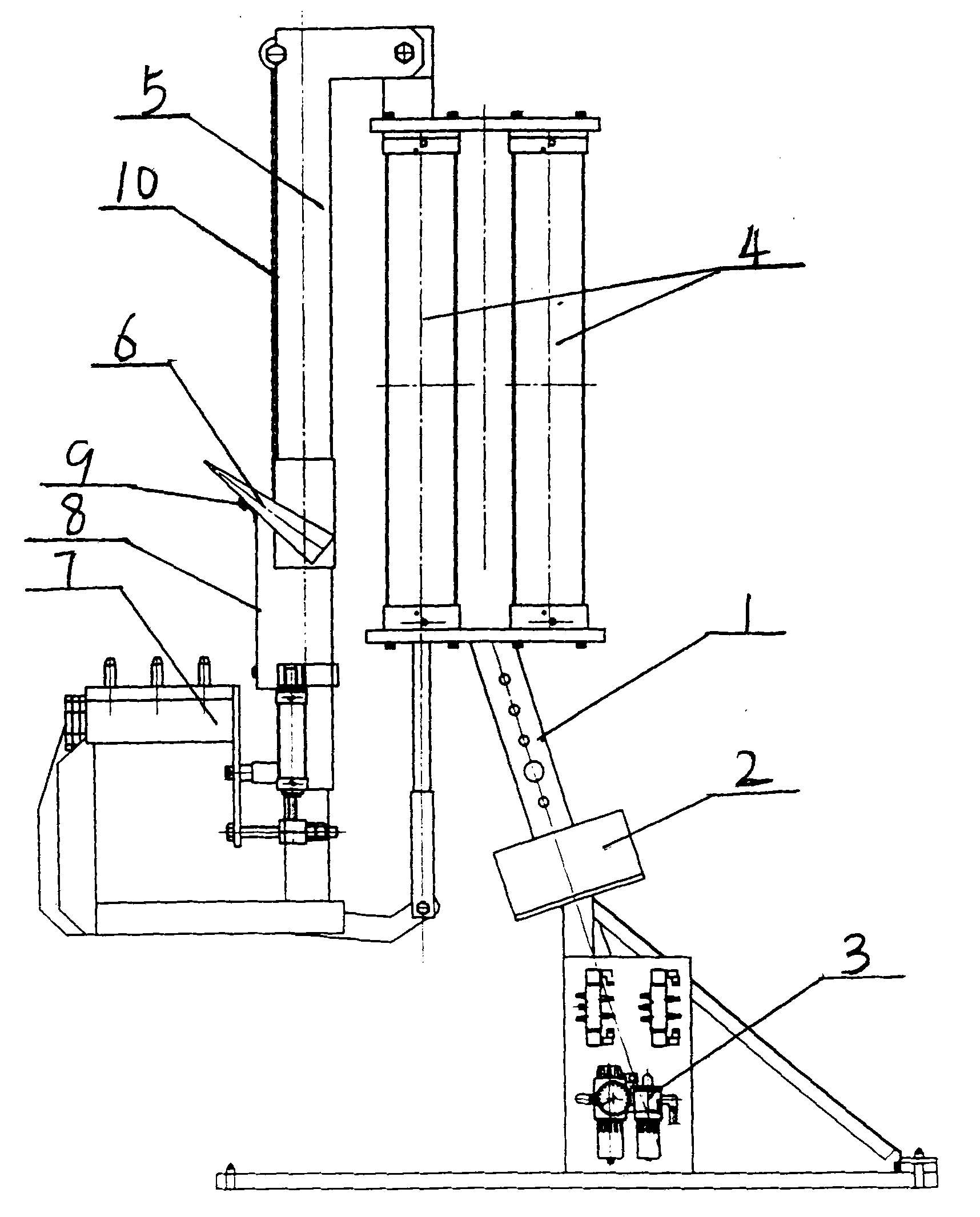

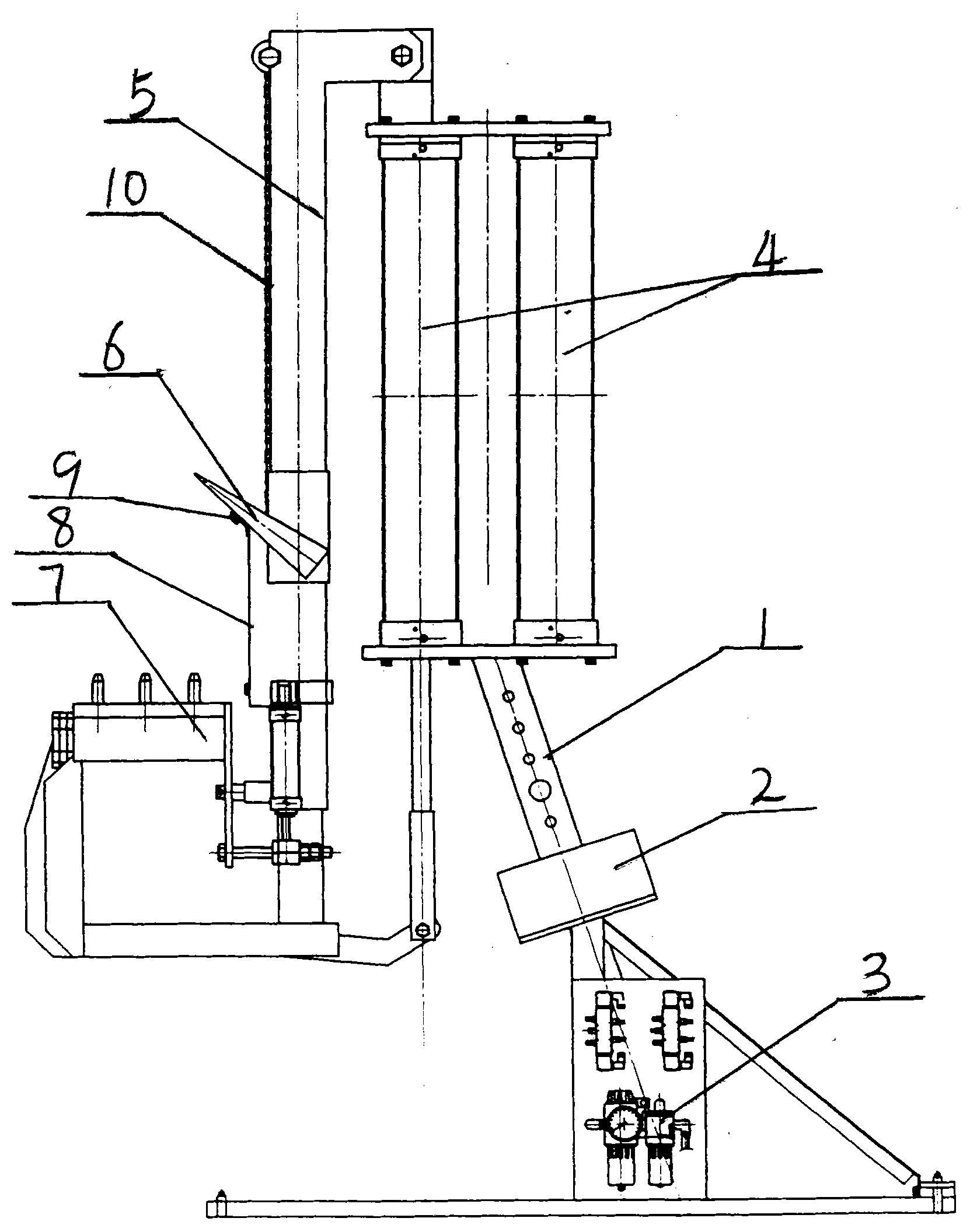

[0015] Such as figure 1 As shown, the mink peeling machine of the present invention comprises a support 1, a control box 2, a filter regulator and an adjusting bolt are installed on the support 1, an oil tank 3 is installed at the bottom of the support 1, a cylinder 4 is installed on the top of the support 1, and the top of the cylinder 4 is connected Slide bar 5 is arranged, and sensor (not shown) is installed on the cylinder 4, and fork frame 6 is installed on the slide bar 5, and adjustable tight frame 7 is installed on the slide bar 5 bottom, and adjustable frame 7 is installed on the fork frame 6. Adjusting bar 8, fork frame 6 is provided with winged nut 9, and chain 10 is installed on slide bar 5, and sensor comprises female mink sensor and male mink sensor, and control box 2 is provided with annular switch and control button, and this fork Sharp teeth are provided on the shape frame 6 and the adjustable tight frame 7 .

[0016] When the mink peeling machine is working,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com