Self-balancing type chassis for four-wheel vehicle

An automatic balancing, four-wheeled vehicle technology, applied in vehicle components, elastic suspension, interconnection systems, etc., can solve problems such as uneven force, vehicle rollover, and the chassis cannot be automatically balanced, and achieve reasonable design and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

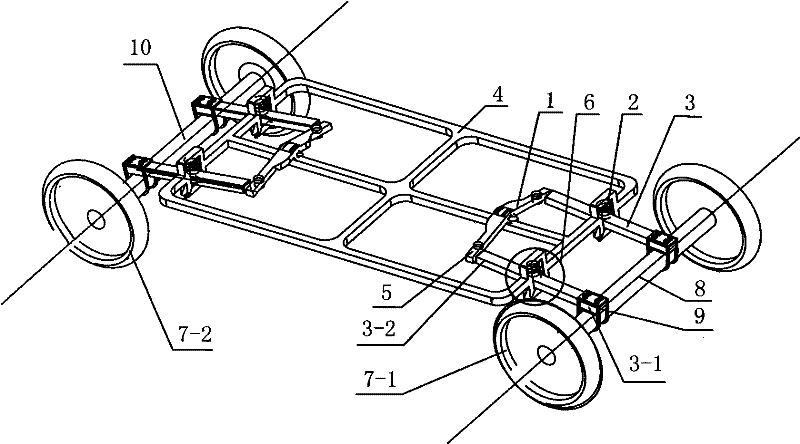

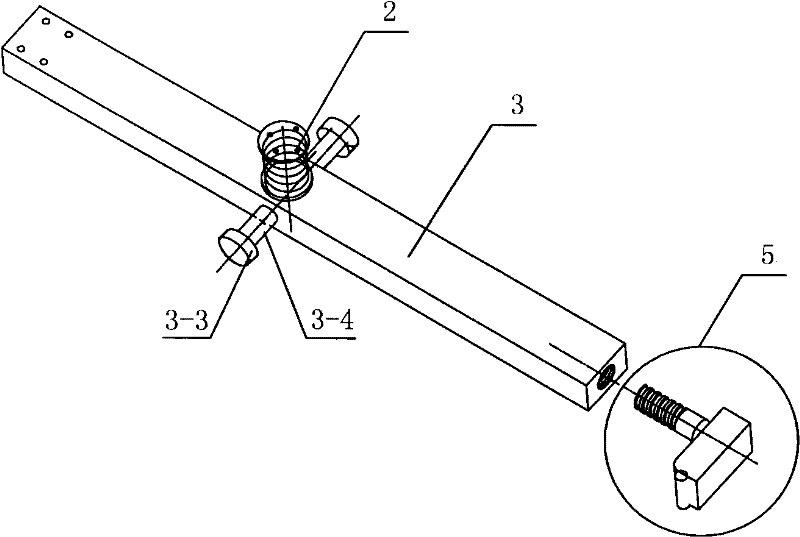

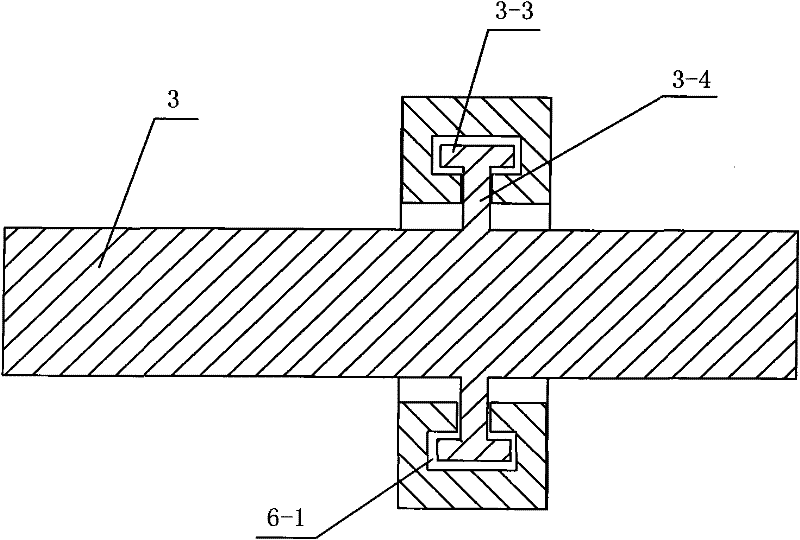

[0016] Refer to attached Figure 1~5 , The self-balancing four-wheel vehicle chassis includes front wheels 7-1, rear wheels 7-2, front axle 8, rear axle 10, vehicle frame 4, balance bar 1, damping spring 2 and extension arm 3. The longitudinal sides of the vehicle frame 4 are respectively provided with outrigger mounting seats 6, and the inner side of the outrigger arm mounting seats 6 is provided with sliding guide rails 6-1 ( image 3 Schematic), the bottom of the outrigger arm mount 6 is equipped with a fixed plate 6-2, and the fixed plate 6-2 is connected with the bottom of the outrigger arm mount 6 by a bolt 6-3 ( Figure 4 hint). Pin shaft 3-4 is housed on the described extension arm, and pin shaft two ends are provided with limit section 3-3 ( figure 2 Schematic), the extended arm is made of rigid structure or spring steel ( figure 2 hint).

[0017] A balance bar 1 is installed at the front part of the vehicle frame 4 and the rear part of the vehicle frame 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com