Automobile bumper energy absorber with high energy absorption performance

A technology for automobile bumpers and energy absorbers, which is applied in the direction of bumpers, etc., which can solve the problems of large structural shape and section size, limited space of energy absorbers, and thin skeleton of energy absorbers, so as to enhance the anti-deformation ability and avoid collision collapse The effect of changing and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

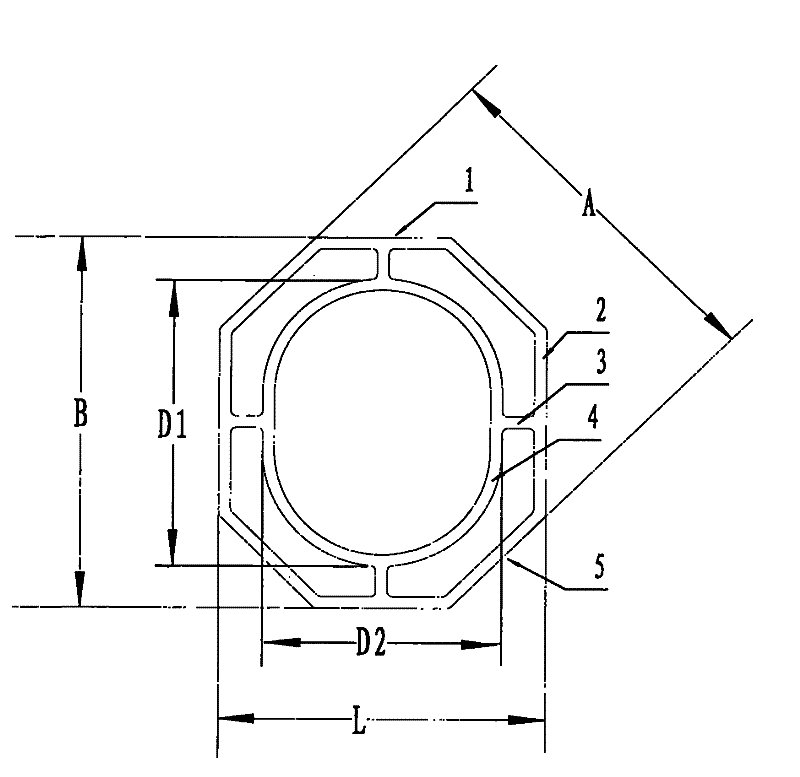

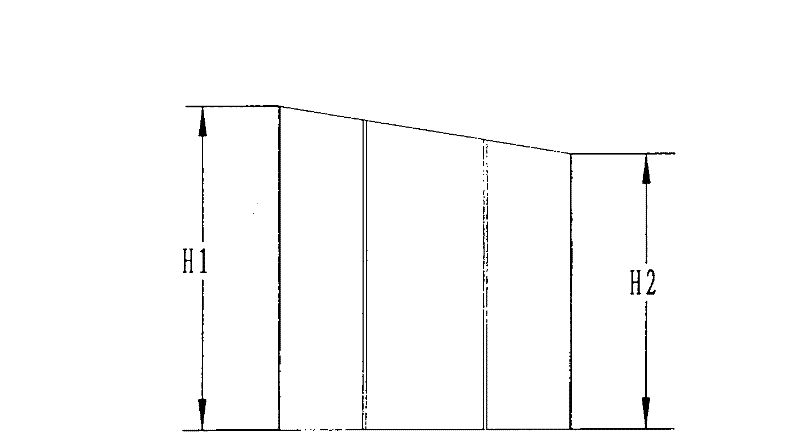

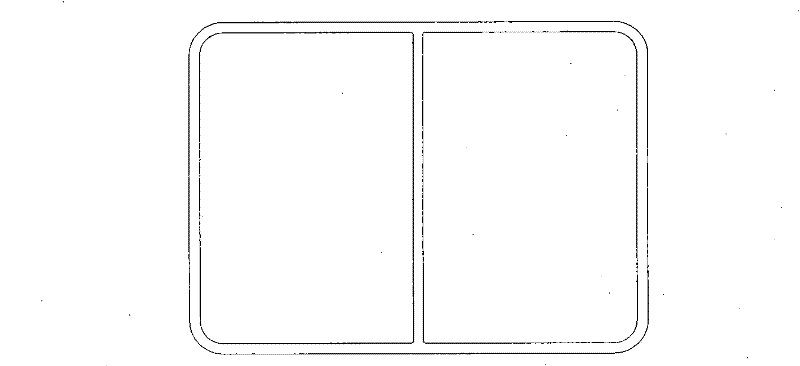

[0017] see figure 1 , figure 2 , The energy absorber of the present invention is composed of an octahedral shell and an elliptical cross-section skeleton located in the shell. The cross section of the energy absorber shell is a symmetrical octagon, which is composed of two long sides 2 corresponding to each other, two short sides 1 corresponding to each other and four equal-length corner sides 5 connecting the long and short sides , the non-regular octahedral design of the shell is mainly considered from the requirements of the installation space of the energy absorber. The cross-section of the energy absorber frame 4 adopts an elliptical design that matches the shape of the shell as much as possible and is close to a circle. There are four reinforcing ribs 3 between the shell and the frame. , The middle part of the short side extends to the skeleton and joins with it. The dimensions of each part of the energy absorber are as follows: the distance L between two correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com