Inner-wall rope-pressing cable drum

A wire rope reel and wire rope technology, applied in the field of inner wall pressure rope type wire rope reel, can solve the problems of large space occupied, laborious replacement of wire rope, increased process difficulty, etc., to simplify structure, save production cost, and reduce process difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

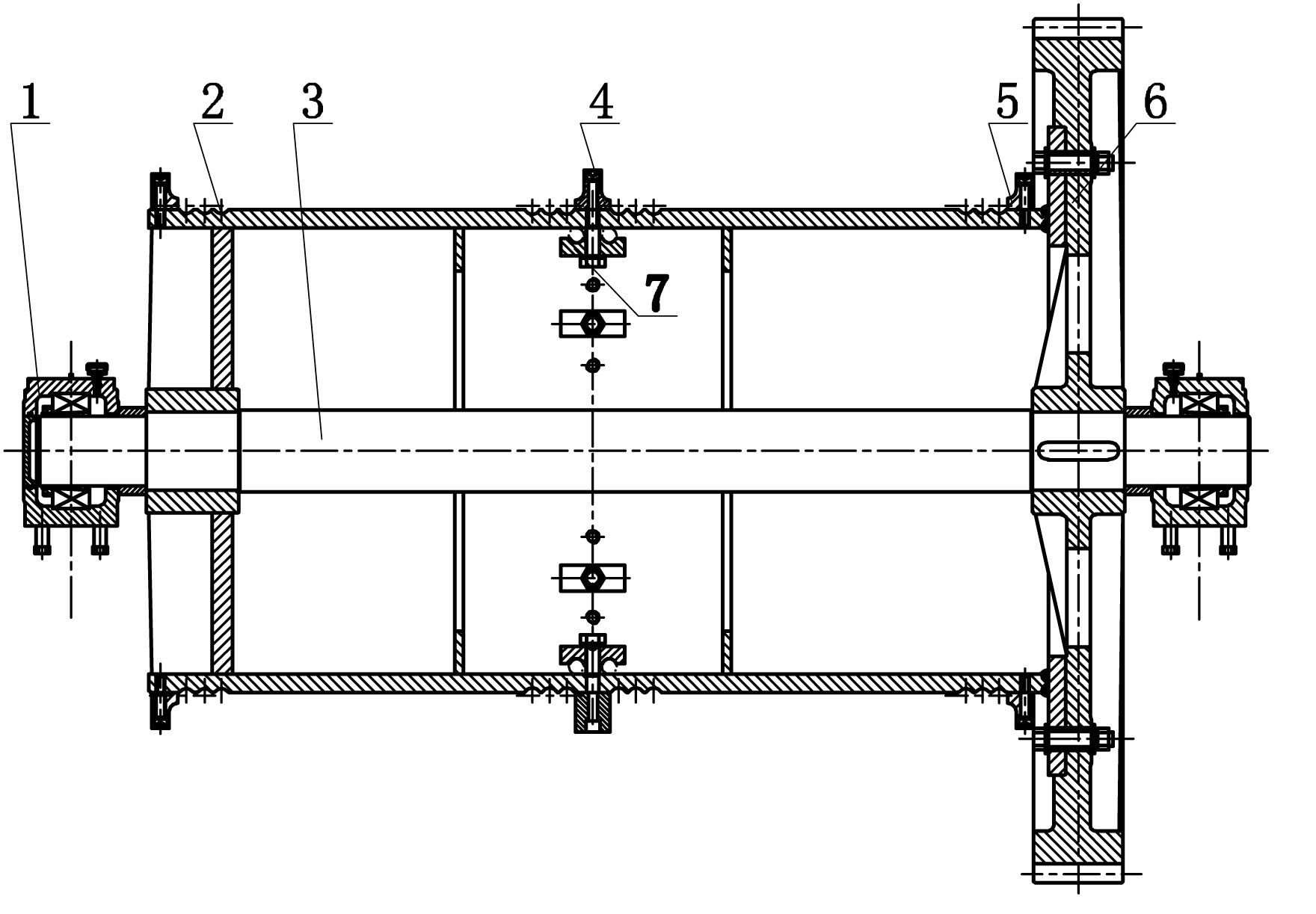

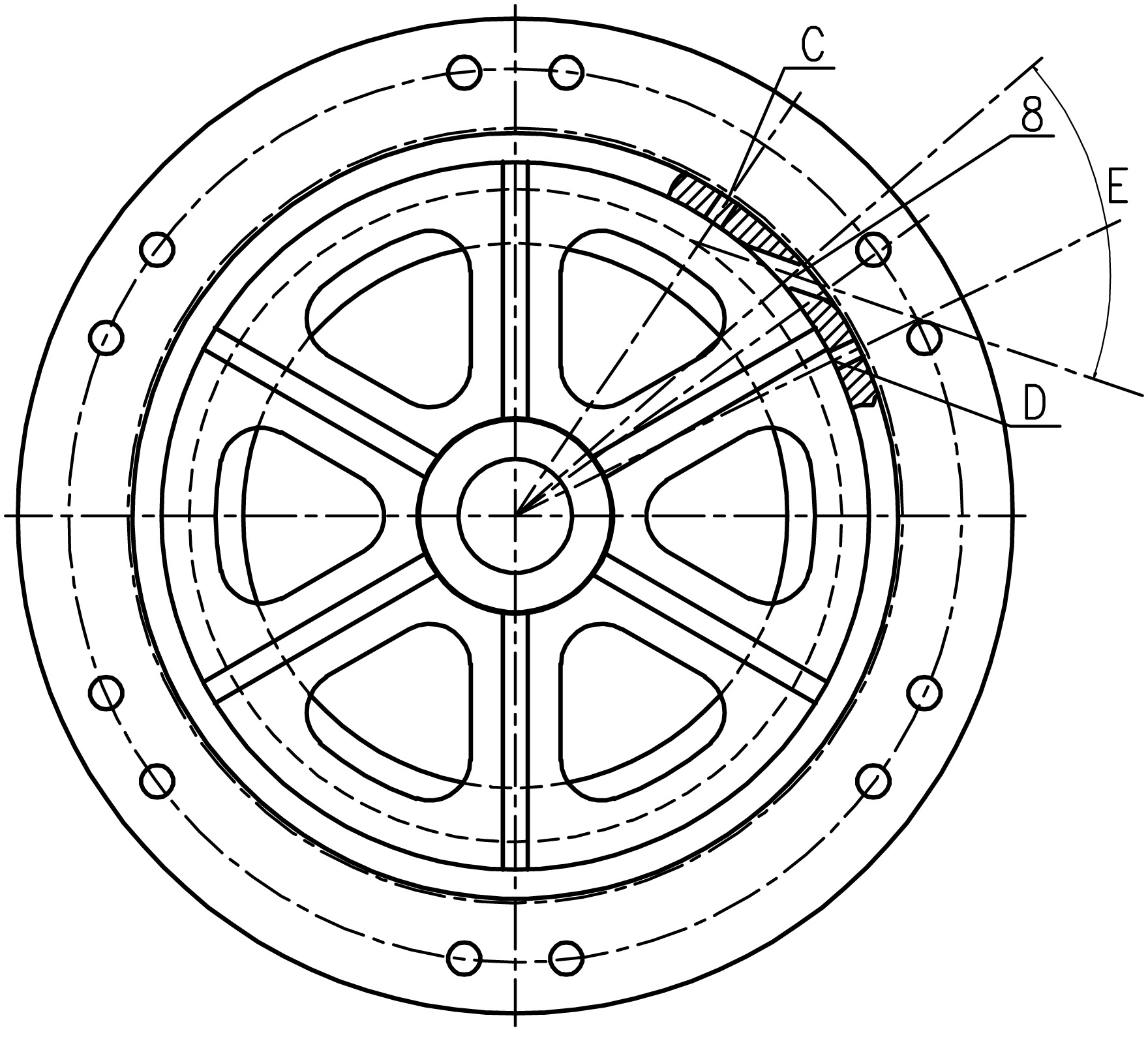

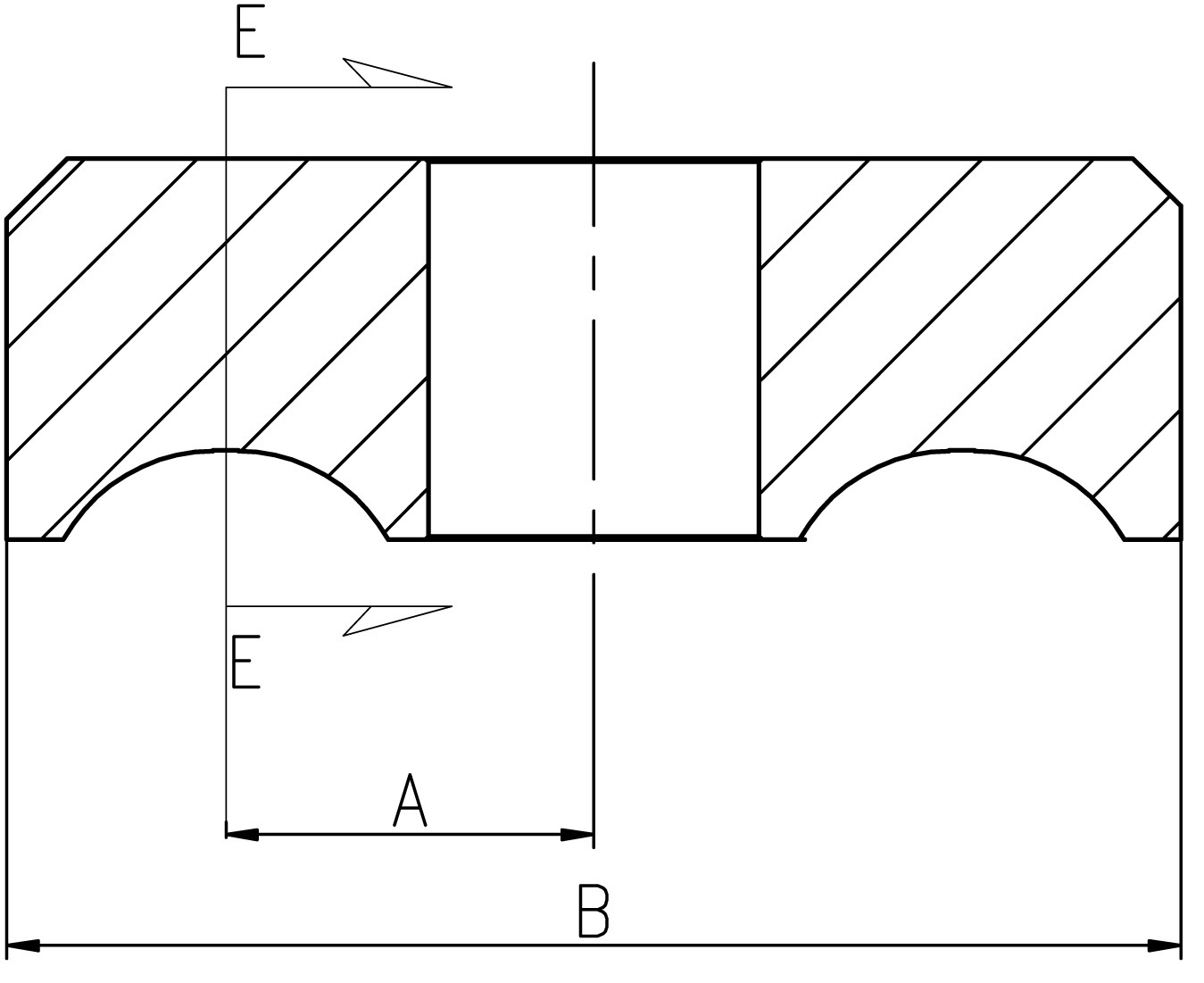

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 Among them, an inner wall pressure rope type wire rope reel, including a reel 2, a reel shaft 3 is arranged inside the reel 2, side return rope rings 5 are provided at both ends of the reel 2, and a middle return rope is provided in the middle of the reel 2. The rope ring 4, the middle return rope ring 4 and the side return rope ring 5 are all fixed on the circumference of the reel 2 by screws, and the gear 6 is fixed on the flange of the reel 2 by hinged bolts or shear sleeves. The end is supported on the bearing seat 1 by the drum shaft 3, and a plurality of wire rope pressure plates 7 are fixed on the drum wall by bolts. The reel 2 between the first and the last wire rope pressing plate 7 is provided with a rope outlet 8, that is figure 2 between C and D.

[0025] During production, the reel 2 is clamped and fixed at first, and the position of the connecting screw hole between the return rope ring and the...

Embodiment 2

[0029] Different from the double drum, the wire rope outlet hole 8 of the single drum is set at the side return rope ring 5, and its steel wire rope pressure plate 7 is also designed with bolts on both sides of the rope groove. By fixing the two bolts to tighten the wire rope.

[0030] The inner wall pressure rope type steel wire rope reel provided by the present invention greatly simplifies the structure of the reel and reduces the difficulty of the process, especially for cranes with large lifting capacity and high lift, it solves the problem of fixing and installing multi-layer winding steel wire ropes, and improves It improves work efficiency and saves engineering cost, so it is worthy of popularization and application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com