Spotlight guide rail and manufacturing method thereof

A technology of guide rails and spotlights, which is applied to lighting devices, components of lighting devices, lighting auxiliary devices, etc. It can solve problems such as increased installation of spotlights, inaccurate positioning of rubber sleeves, and contact between copper core and metal guide rails, etc., to achieve It is safe and reliable to use, simple and reasonable in structure, and avoids the effect of bad contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically described below in conjunction with specific embodiments.

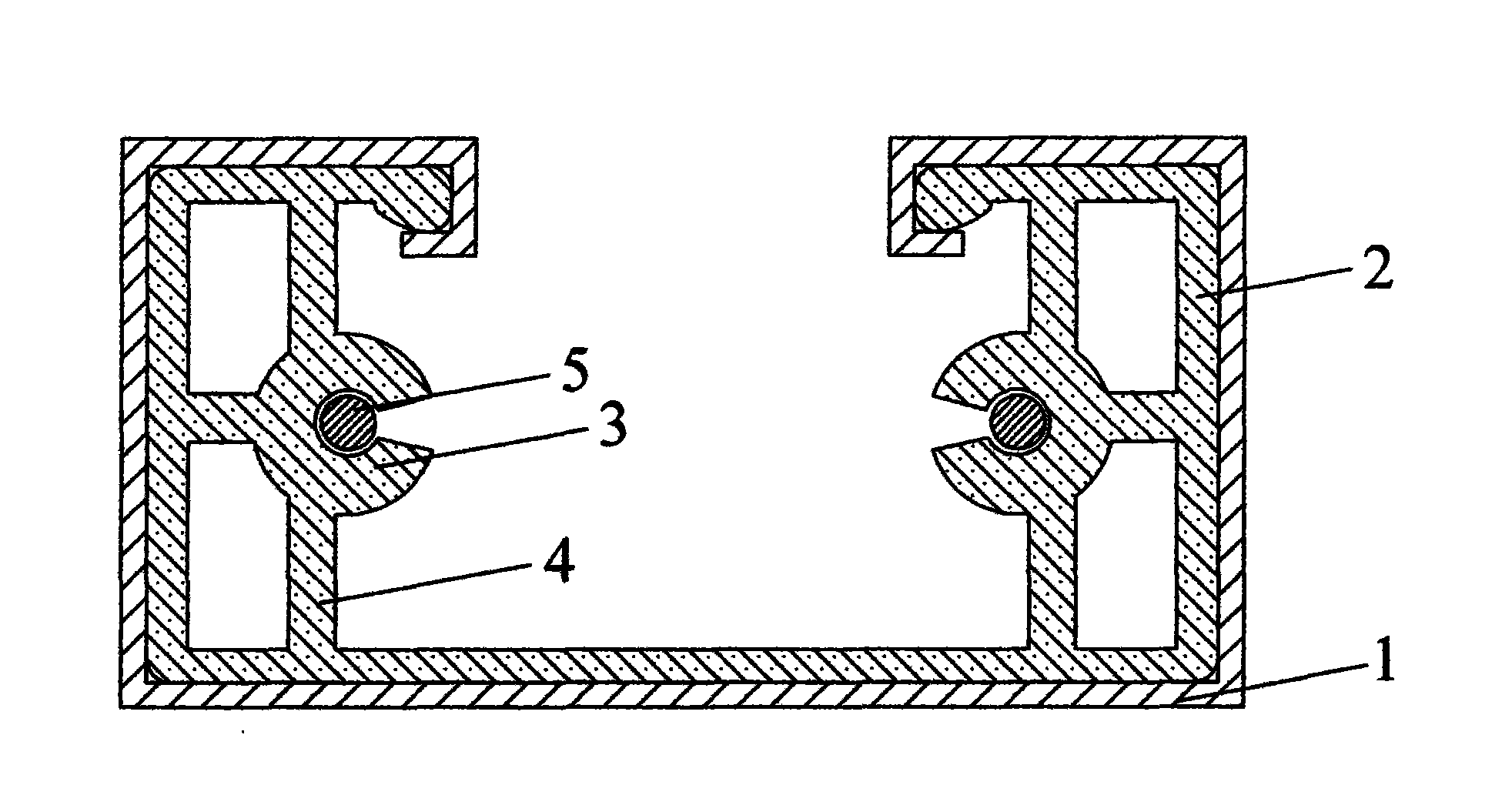

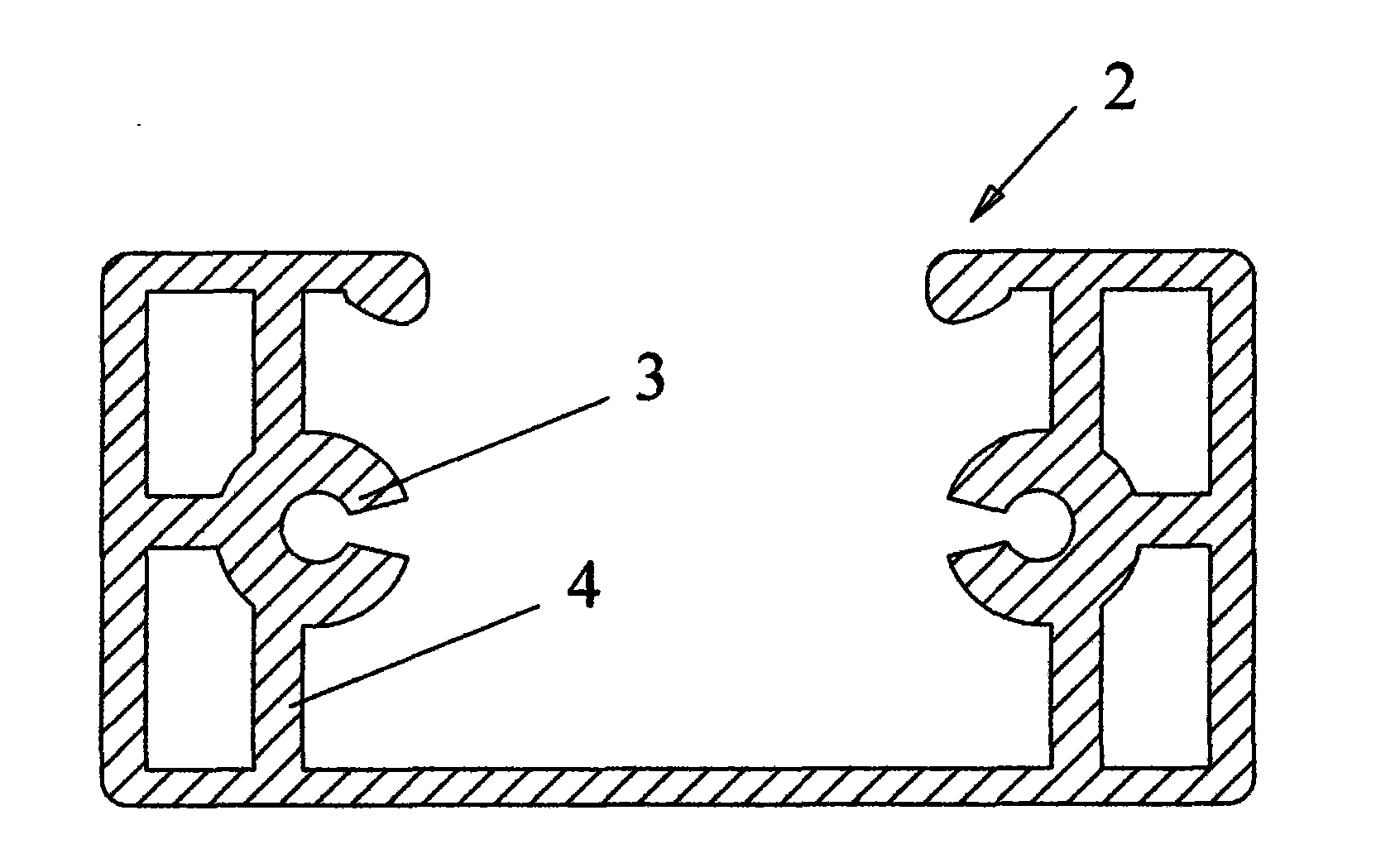

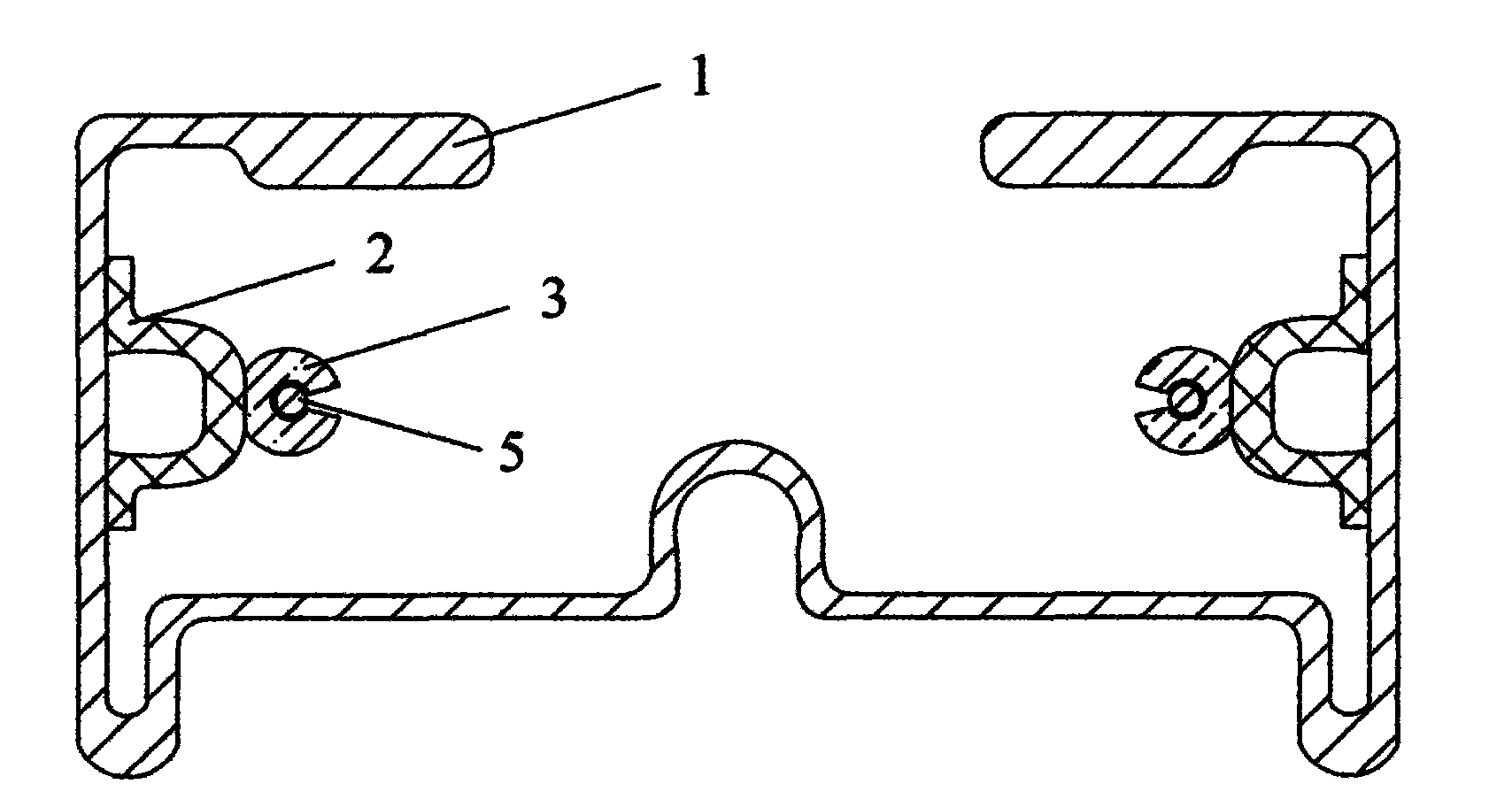

[0023] Such as figure 1 , figure 2 As shown, a spotlight guide rail includes a guide rail base 1, a rubber sleeve 2 and a copper core 5, the rubber sleeve 2 is embedded in the guide rail base 1, and the outer surface of the rubber sleeve 2 is attached to the On the inside surface of the guide rail base body, the inside of the rubber sleeve 2 is also provided with at least two slots 3 for clamping the copper core. In this embodiment, the number of slots 3 is two, and the two slots 3 The slots 3 are arranged in a relative structure. The rubber sleeve 2 and the card slot 3 are connected together and made by one-piece injection molding; the edge parts on both sides of the guide rail base 1 are bent and tightly wrapped around the edge parts on both sides of the rubber sleeve; the guide rail base 1 is made of metal material production. There is a gap between the card s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com