Motorboat body overturning roll cage device

A hull and rolling rack technology, which is applied to ships, transportation and packaging, and ship parts, and can solve problems such as hull deformation and hidden safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

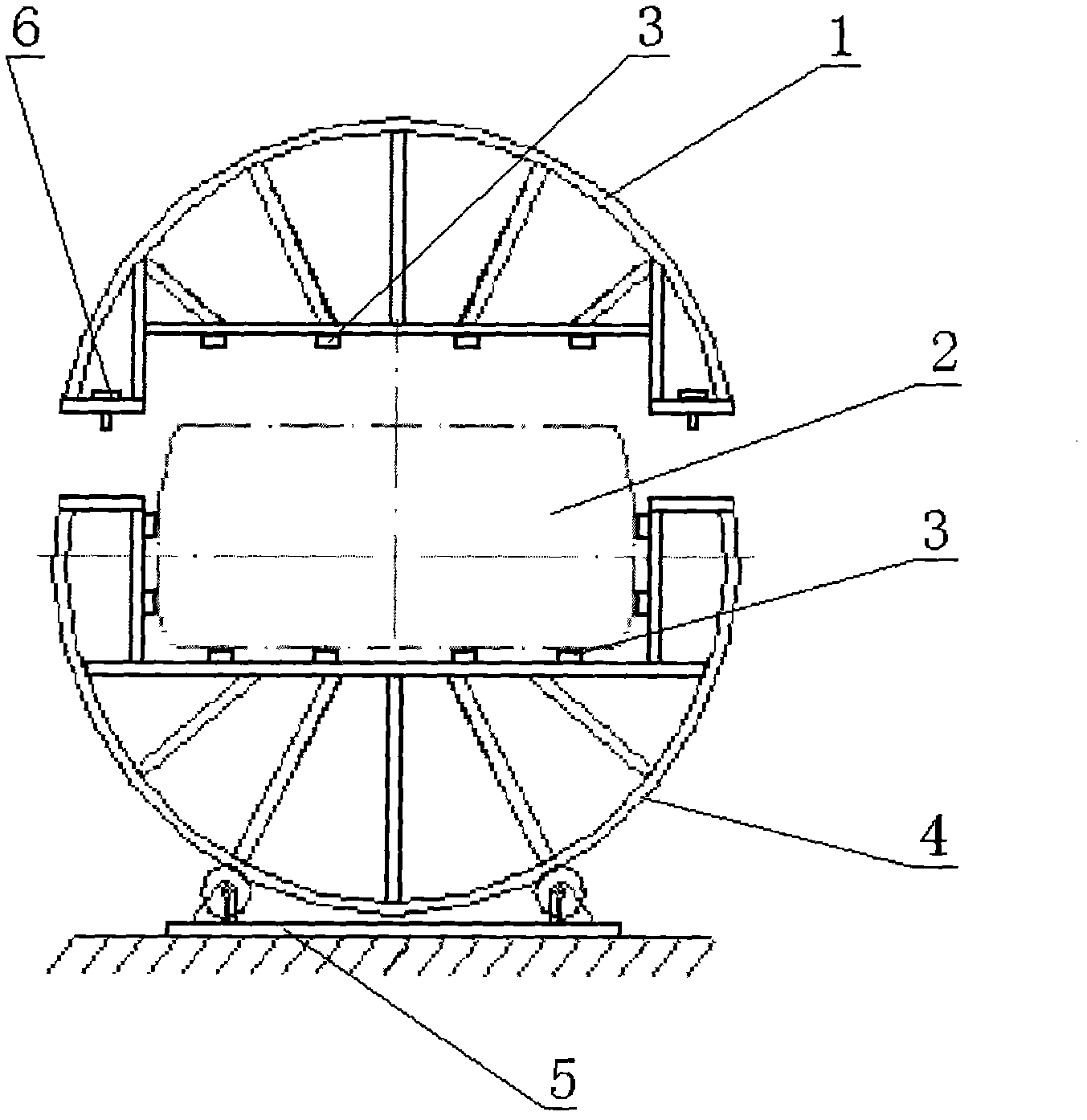

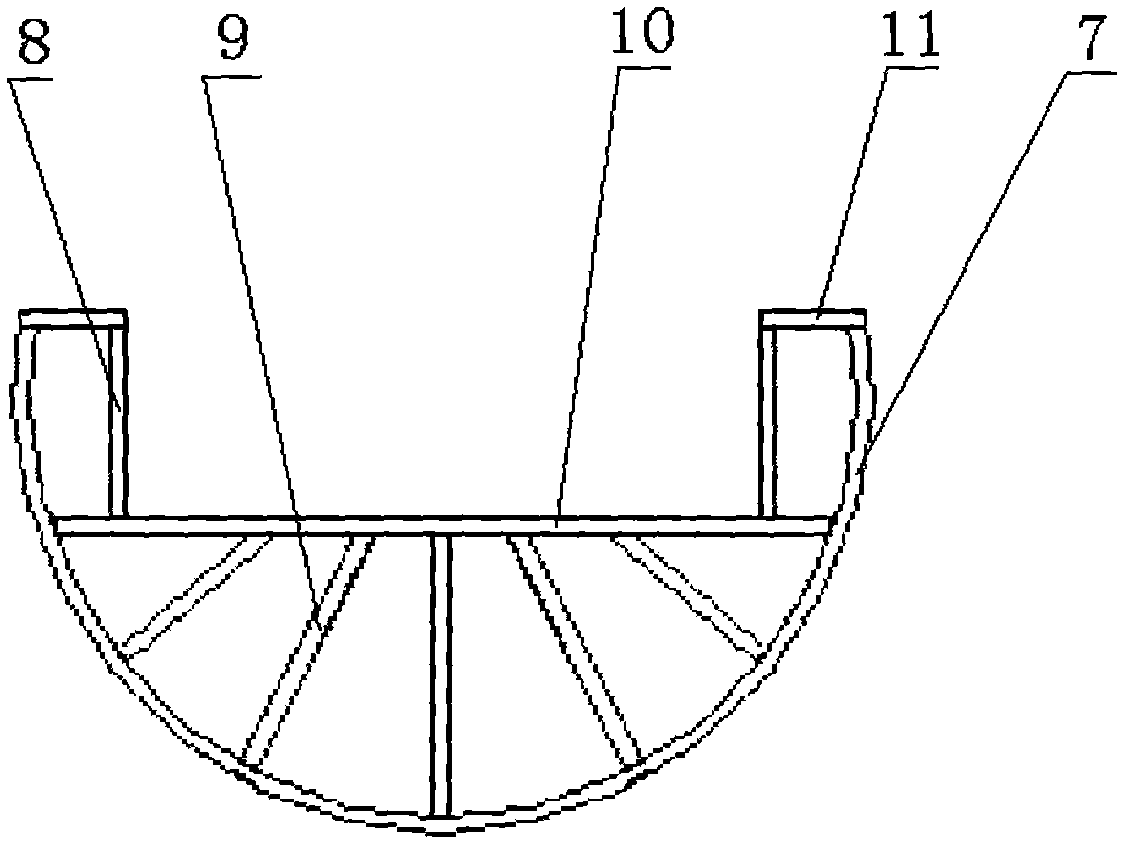

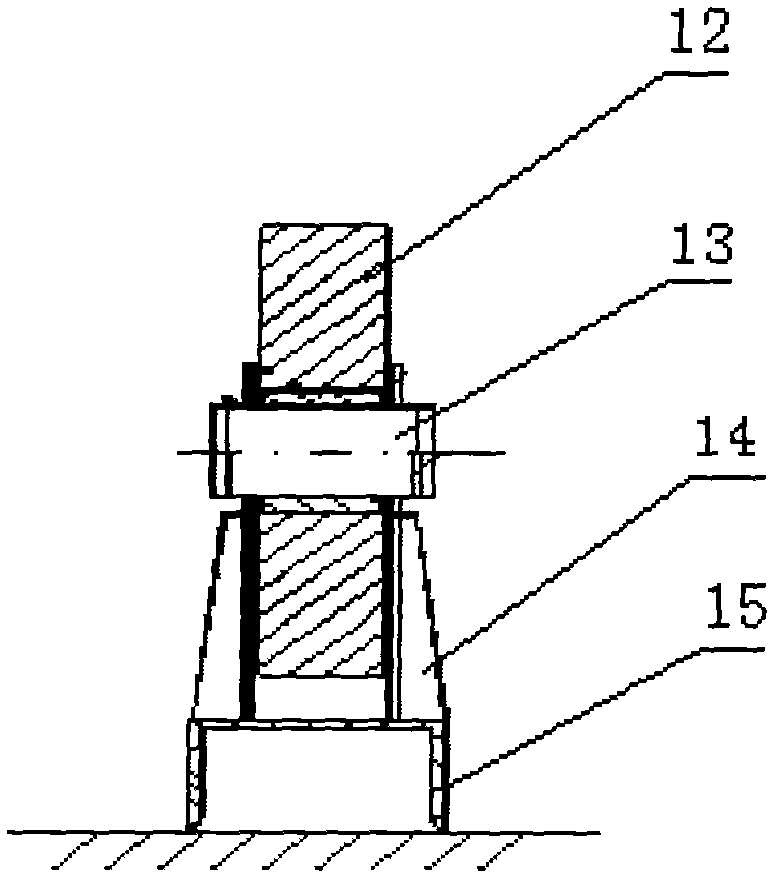

[0014] Such as figure 1 , figure 2 , image 3 As shown, the rolling rack device for the motorboat hull is composed of a rounded bracket 5, a rounded upper half 1, a rounded lower half 4, and a half joint 6 that connects the rounded upper half 1 and the rounded lower half 4 together. Composition, the rolling bracket 5 includes a foot plate 15, two spaced roller support seats 14 above the foot plate 15, each of the roller support seats 14 has a roller 12, and the roller 12 can rotate around the axis of the rotating shaft 6 , the foot plate 15 adopts an angle steel structure, the rounded upper half 1 and the rounded lower half 4 have a space suitable for the hull 2 after being closed, and the rounded upper half 1 and the rounded lower half 4 are set There are a plurality of corrugated support parts 3 for fastening the hull 2, each corrugated support part 3 includes corrugated wood, a corrugated wood support seat and a screw rod, and the distance between the corrugated wood a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com