Steering conveying system and device

A technology of conveying device and steering device, applied in the field of machinery, can solve the problems of large energy loss, high production cost, inability to meet the layout of multiple production lines, etc., and achieve the effect of saving production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

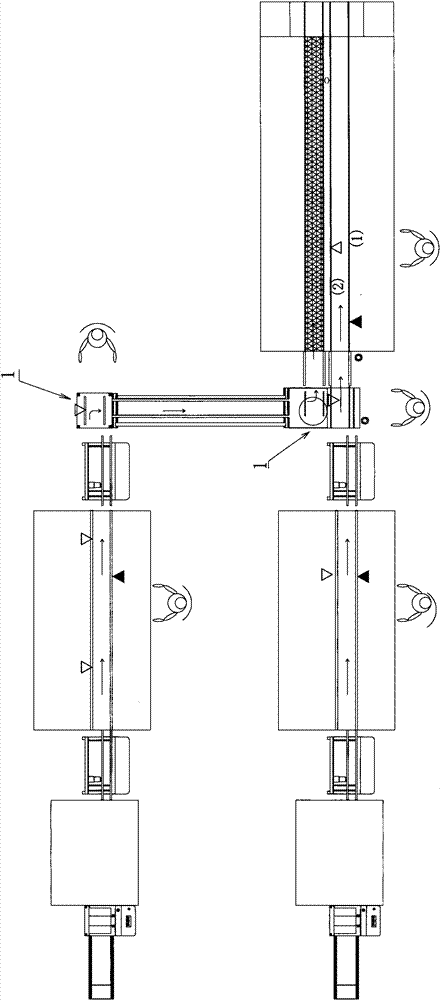

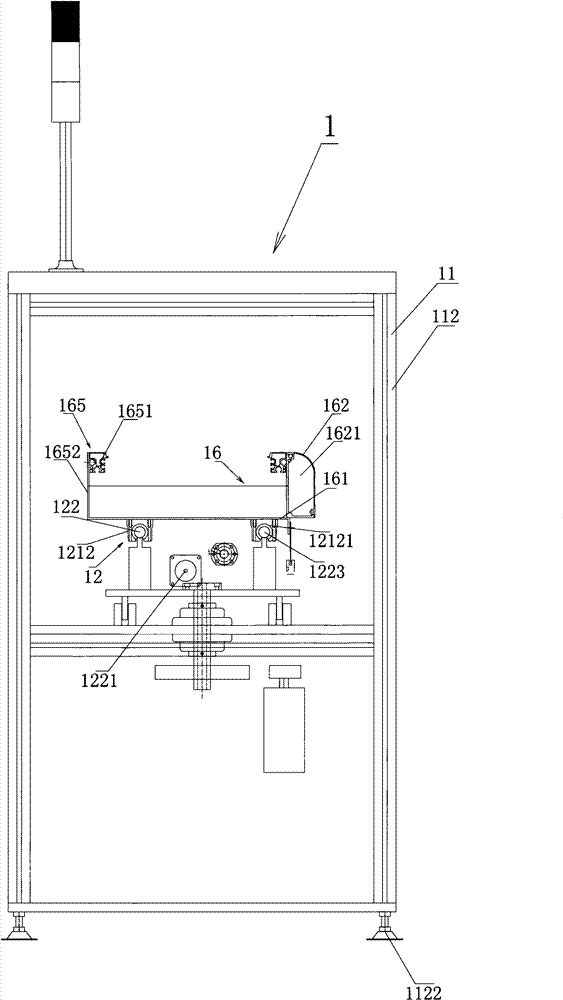

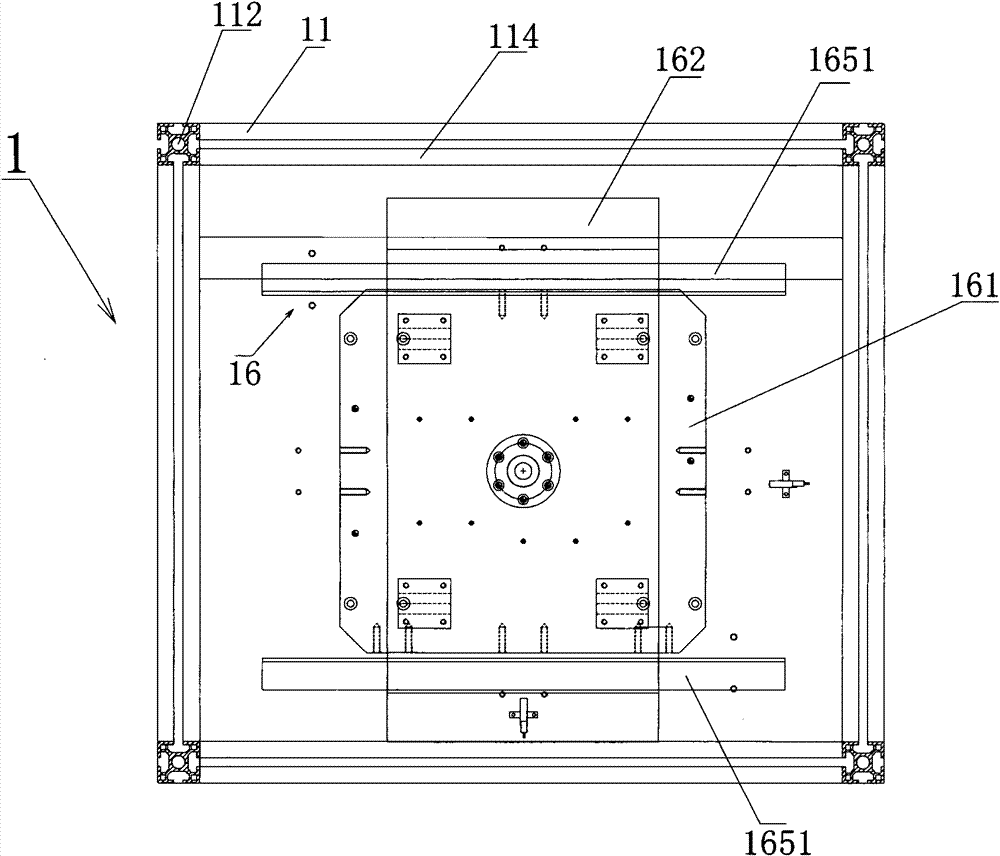

[0030] see in conjunction figure 1 , figure 2 , image 3 as well as Figure 5 , the steering and conveying device provided by the embodiment of the present invention is used for the steering and transportation of circuit boards in surface mount production. After the circuit board is pasted by a surface mount equipment, the circuit board is transferred to The reflow oven equipment that is transported to the production line where the other surface mount equipment is located realizes the sharing of one solder oven for more than two surface mount equipment, thereby achieving the purpose of energy saving and emission reduction. The steering conveying device includes a steering motor The steering device 1 that drives the steering plate to rotate also includes: a stepping assembly 12, a telescopic assembly and a transmission assembly 16, the stepping assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com