Main girder square steel splicing structure on escalator or moving pavement

A technology for moving walks and escalators, applied in escalators, welding equipment, transportation and packaging, etc., can solve problems such as inability to meet, increase the number of metal skeleton segments, and increase the production cost of metal skeletons, so as to reduce production costs and reduce The effect of metal skeleton segmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The structure of the present invention will be further explained below in conjunction with the drawings.

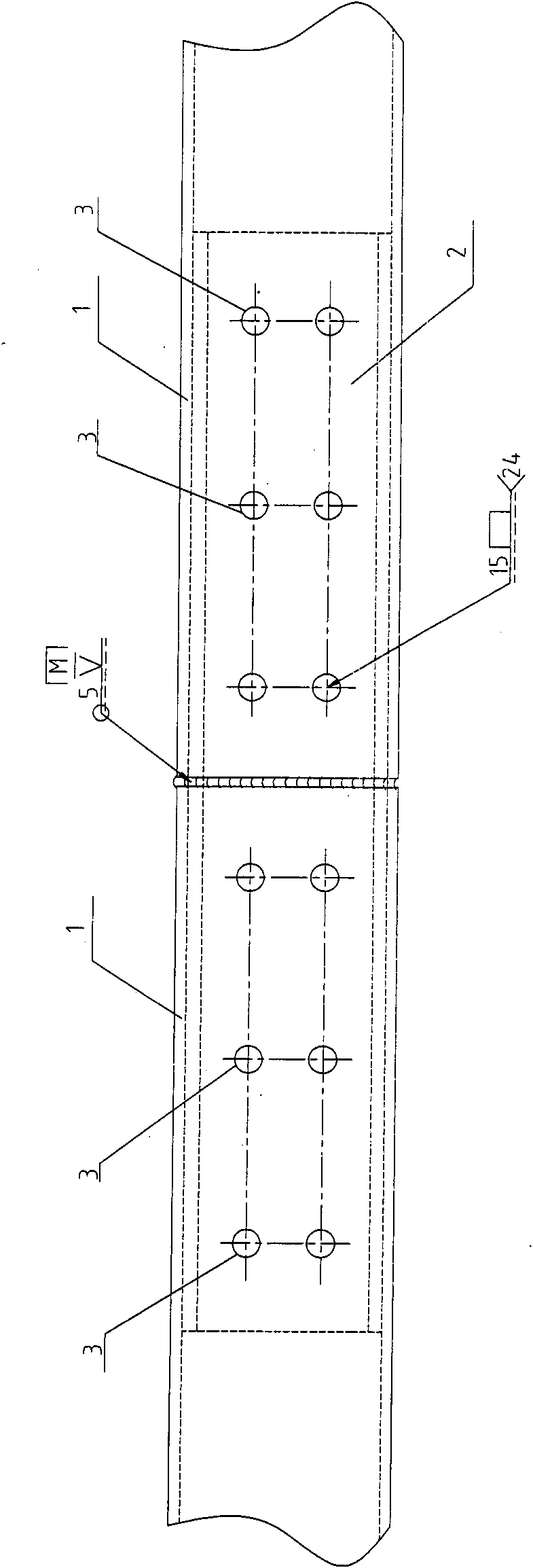

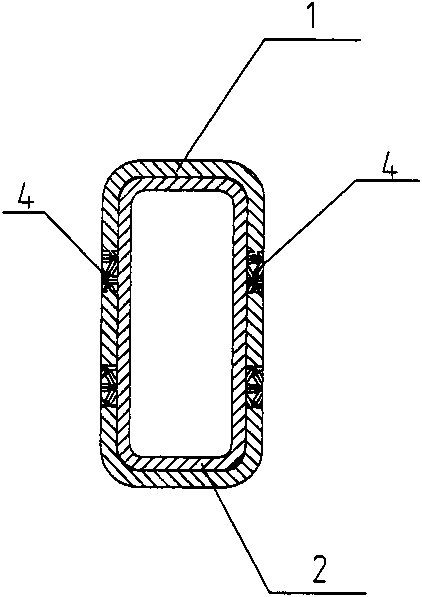

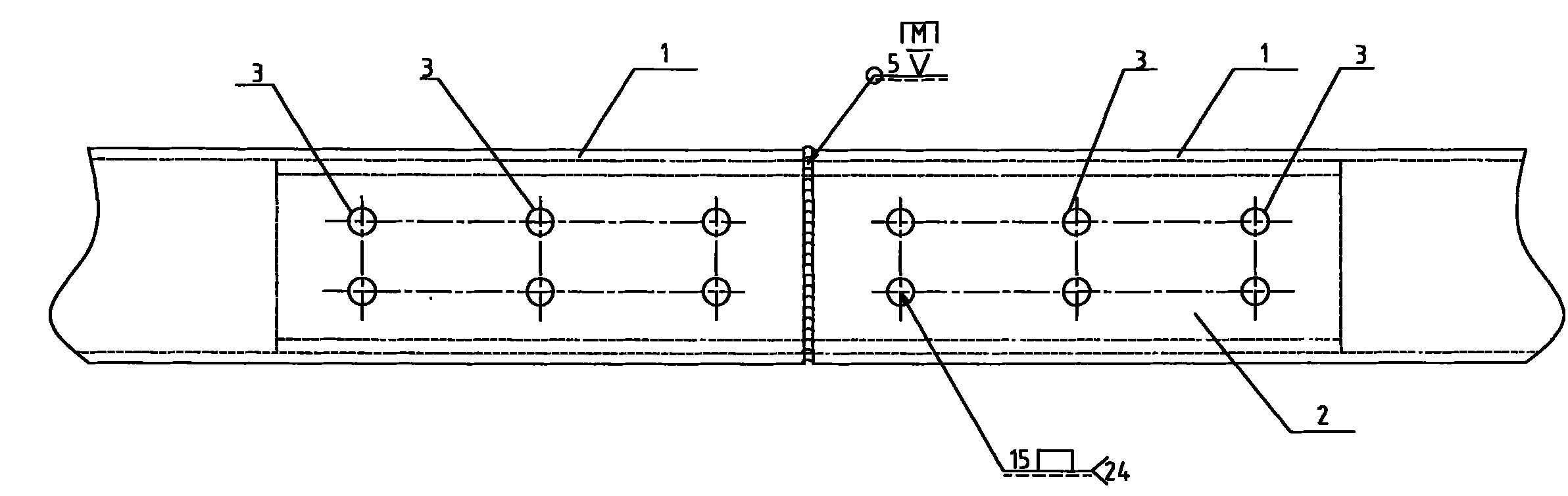

[0010] See Figure 1-2 As shown, the main beam square steel splicing structure on the escalator or moving sidewalk includes two main beam square steel 1, the ends of the two main beam square steel 1 are fixed together by permanent butt welding with backing plates, and the backing plates are reinforced square steel 2 , The two ends of the reinforced square steel 2 respectively extend into the inner cavity of the ends of the two main beam square steel 1, during butt welding, the butt weld of the two main beam square steel 1 is filled with flux, and the weld is ground after the welding is completed Flat, reinforced square steel 2 as a permanent backing plate is also welded and fixed in the two main beam square steel 1. The outer surface of the two main beam square steel 1 ends is provided with multiple perforations 3, and the perforations 3 are filled with melted flux 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com