Installation mechanism of iron clad battery

A technology of installation mechanism and iron shell, applied to the installation mechanism of iron shell battery, the mechanism of automatic charging of the battery, automatic sealing mechanism, and automatic falling of the upper and lower rubber rings, can solve the problem of high labor cost and labor intensity, and the upper rubber ring is brought out. , many people and other problems, to achieve the effect of reducing labor intensity, saving production costs, and reducing the number of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

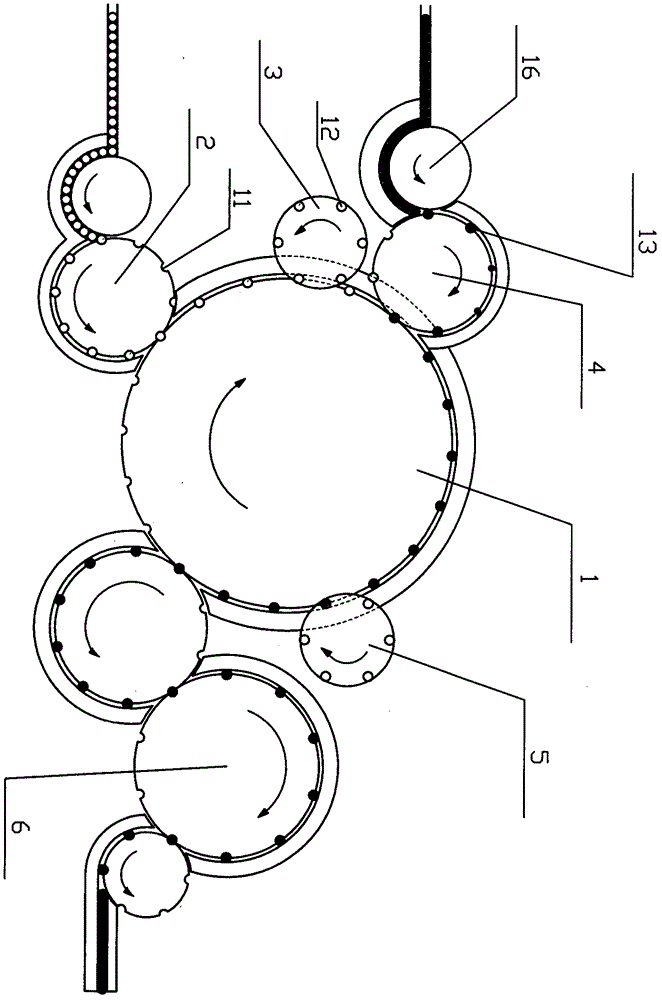

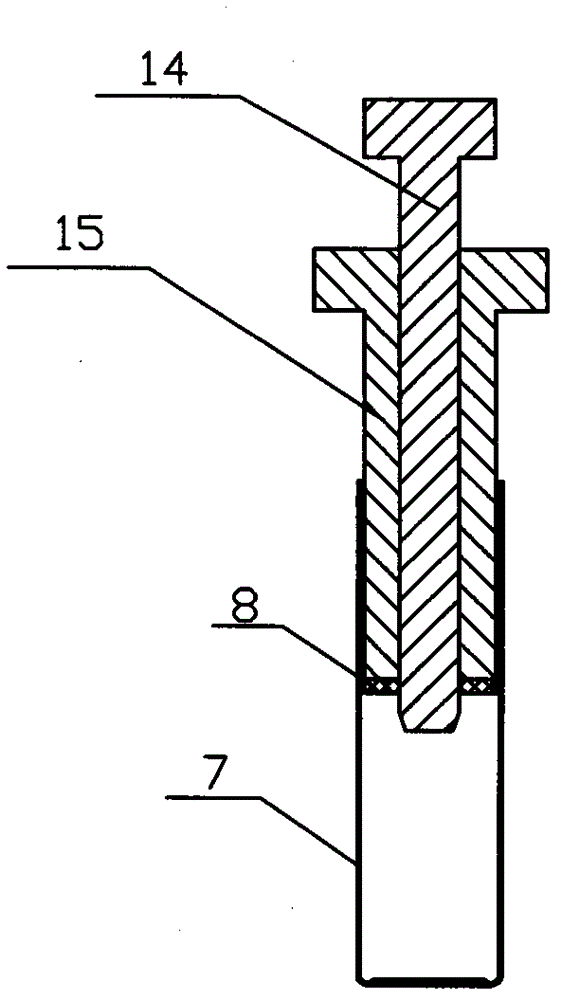

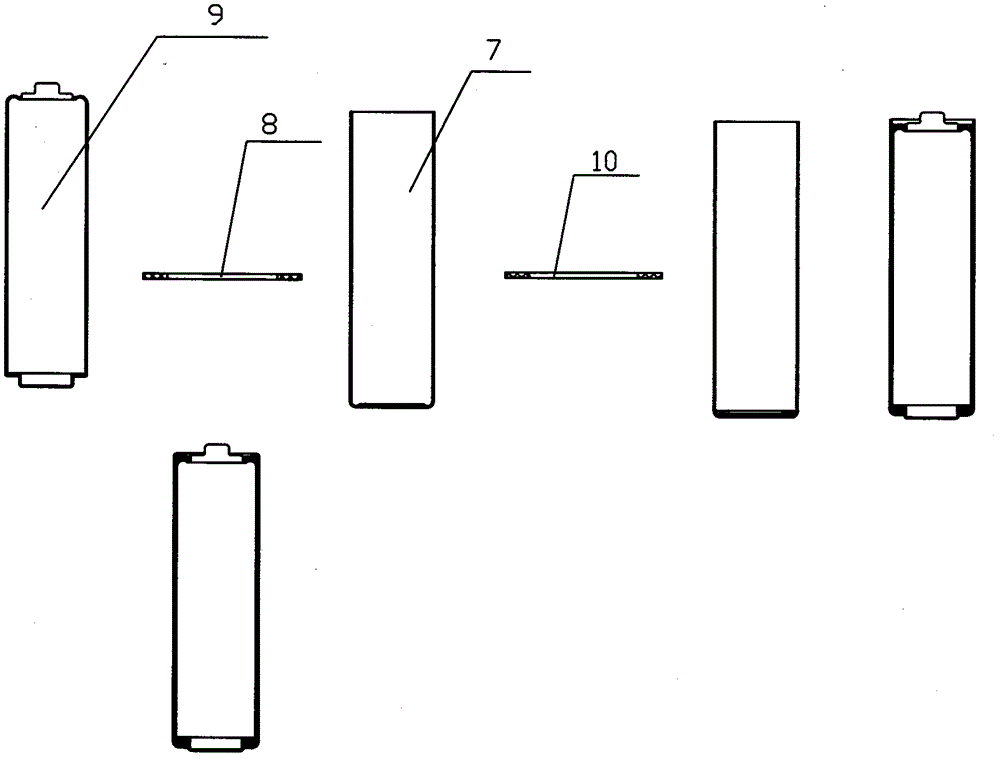

[0014] A mounting mechanism for an iron-cased battery in an embodiment of the present invention, such as figure 1 , figure 2 , image 3 As shown, it includes a first conveying tray 1 that can absorb and fix the iron shell 7, a second conveying tray 2 connected with the first conveying tray to convey the iron shell, and connected with the first conveying tray so that the rubber ring 8 falls into the iron shell The third conveying tray 3 connected with the first conveying tray so that the semi-finished zinc cylinder battery 9 falls into the iron shell the fourth conveying tray 4 connected with the first conveying tray so that the upper rubber ring 10 falls into the iron shell the fifth conveying tray 5. Connect to the sixth delivery tray 6 that seals the battery with the first delivery tray, and the second, third, fourth, fifth, and sixth delivery trays are arranged around the first delivery tray in turn; the first, second, The sixth conveying tray is provided with a first no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com