A kind of mixing method for strengthening the auxiliary machine of internal mixer

A technology of internal mixer and lower auxiliary machine, which is applied in the field of strengthening the mixing of the lower auxiliary machine of internal mixer, which can solve the problems of the influence of rubber dispersion quality, increase of rubber parking area, and difficulty in filler dispersion, so as to ensure the dispersion of sulfur , saving energy, good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

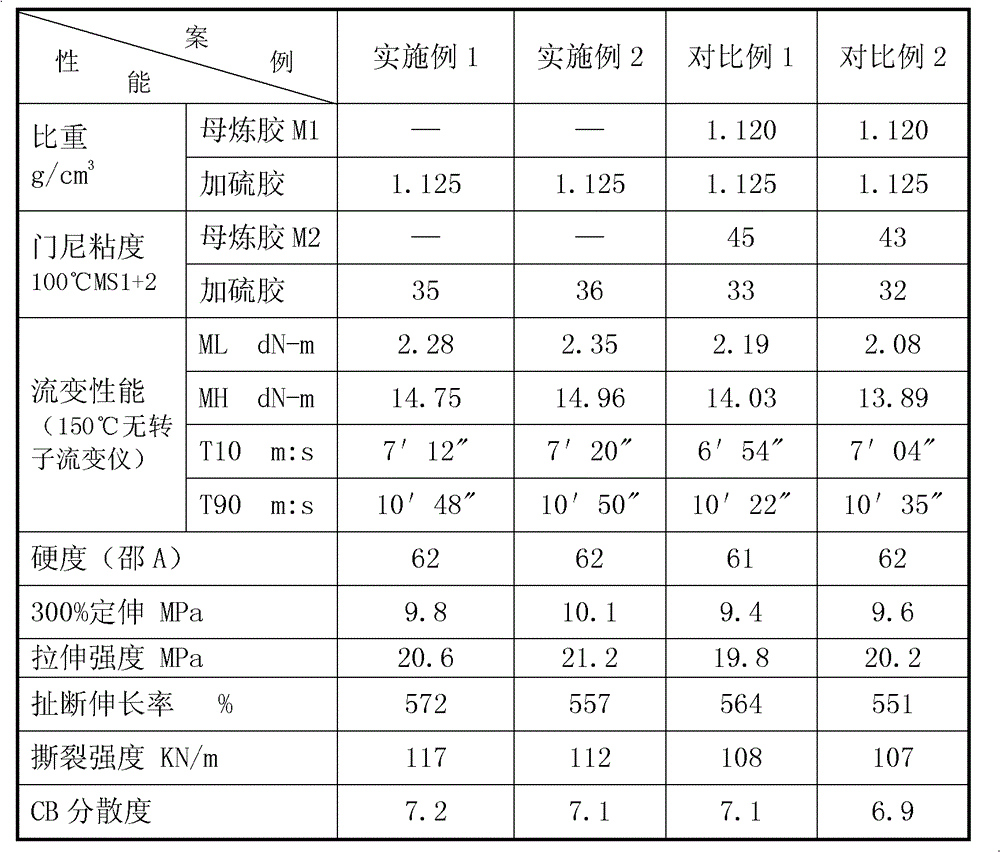

Examples

Embodiment 1

[0032] This strengthens the mixing method of the lower auxiliary machine of the internal mixer, selects one high-speed internal mixer with 1 to 3 lower auxiliary machines of the internal mixer, and selects according to the different types of internal mixers selected and the actual situation. In this embodiment, a GK-270 (20 / 40r / min) high-speed internal mixer and an open mixer with a drilled smooth roller matched with it are selected as the auxiliary machine to form a one-time internal mixing mixer. Machine production line, in which the length of the conveyor belt is 12 meters.

[0033] Tread rubber formula (mass ratio): 3# smoked sheet rubber 50, butadiene rubber BR900050, zinc oxide 4, stearic acid 2, protective wax 1.5, anti-aging agent 40202.5, peptizer SJ-1030.3, precipitation white carbon Black 5, carbon black N22055, aromatic oil 14, accelerator NS1.05, sulfur 1.65

[0034] First use the internal mixer to mix the masterbatch. The speed of the internal mixer is 40r / min, ...

Embodiment 2

[0049] The mixing method of the auxiliary machine under the strengthened internal mixer of the present embodiment selects one XM-370 (6~60r / min) high-speed internal mixer and the open mixer of two drilling smooth roller type rollers matched with it as The lower auxiliary machine constitutes an internal mixer production line that completes mixing at one time, and the length of the conveyor belt is 15 meters.

[0050] Tread rubber formula: same as embodiment 1

[0051] First use the internal mixer to mix the masterbatch. The speed of the internal mixer is 60r / min, and the pressure of the top bolt is 0.7MPa. The mixing process is as follows: Open the top bolt and remove the glue. The temperature of the glue removal is 170°C.

[0052] The entire mixing process above, including the lifting and lowering of the top bolt, takes about 155 seconds in total.

[0053] After the internal mixer has mixed the first rubber material, the rubber material is discharged into the first lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com