Method for weighing and loading granular goods

A cargo and granule technology, applied in the field of weighing and loading of granule cargo, can solve the problems affecting the loading speed, loading delay, and failure to reach the rated loading capacity of the carriage, so as to reduce penalties for breach of contract and improve accuracy , Reduce the effect of manual feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

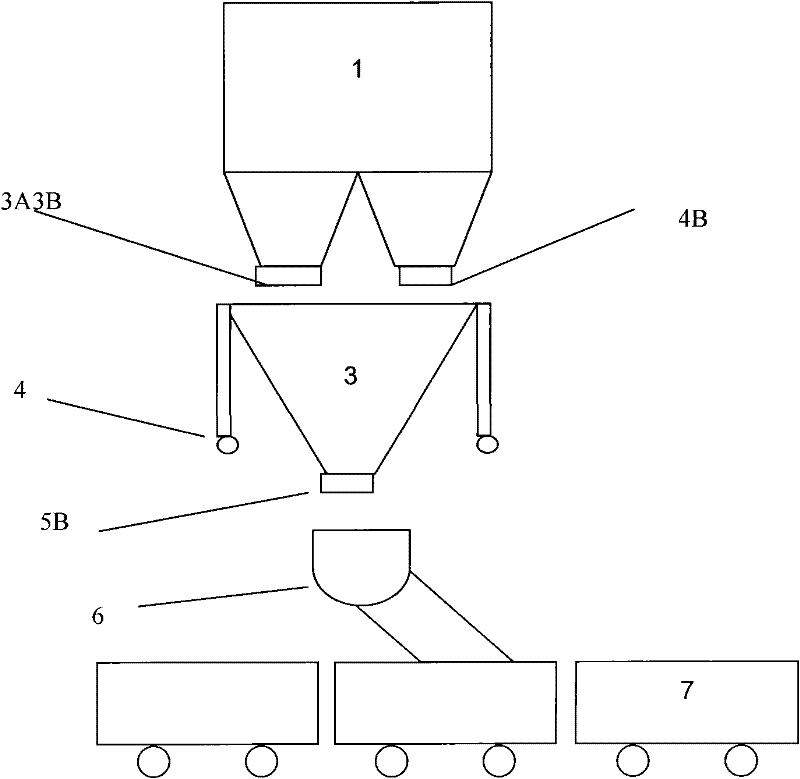

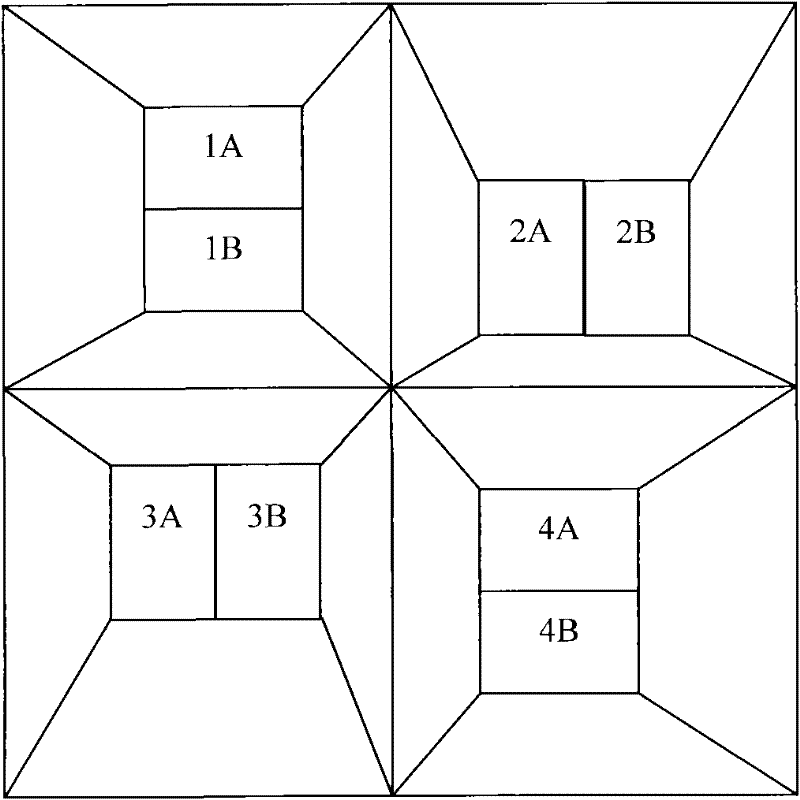

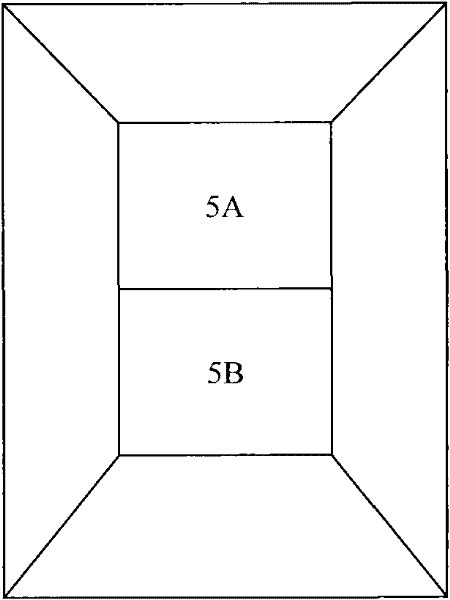

[0022] figure 1 , figure 2 and image 3 As shown, the weighing and loading device for granular cargo. Below is that the present invention uses program-controlled PLC to control the coal loading train to be embodiment.

[0023] Buffer bin 1 can hold 300 tons of coal. After the train enters the station, the staff will register the car number of the whole train, and then input the train number into the electrical automatic control system of the program-controlled PLC section by section, and the electrical automatic control system of the program-controlled PLC will analyze it. The rated loading capacity of the carriage is 63 tons. The method of weighing coal and loading it into the train is as follows:

[0024] Coal is supplied to the buffer bin 1 by a belt conveyor. When the amount of coal in the buffer bin 1 reaches 200 tons, the hydraulic flat unlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com