Process configuration method for integrating high-rack storage into aluminum plate strip production facilities

A high-bay warehouse and configuration method technology, which is applied in the direction of metal rolling, can solve the problems of disconnected production processes and large production workshops, and achieve the effects of short transportation distance, short production cycle and saving production workshops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

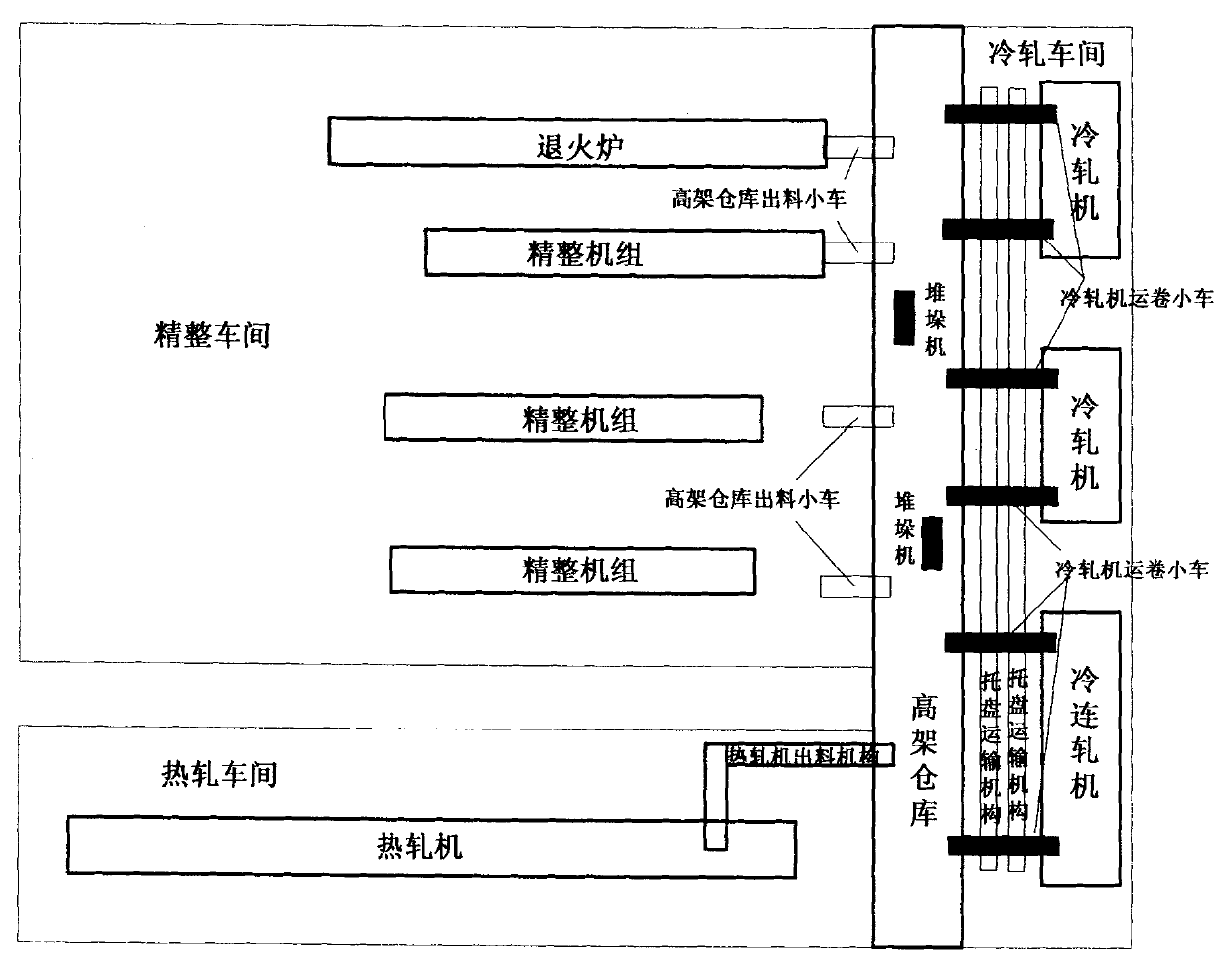

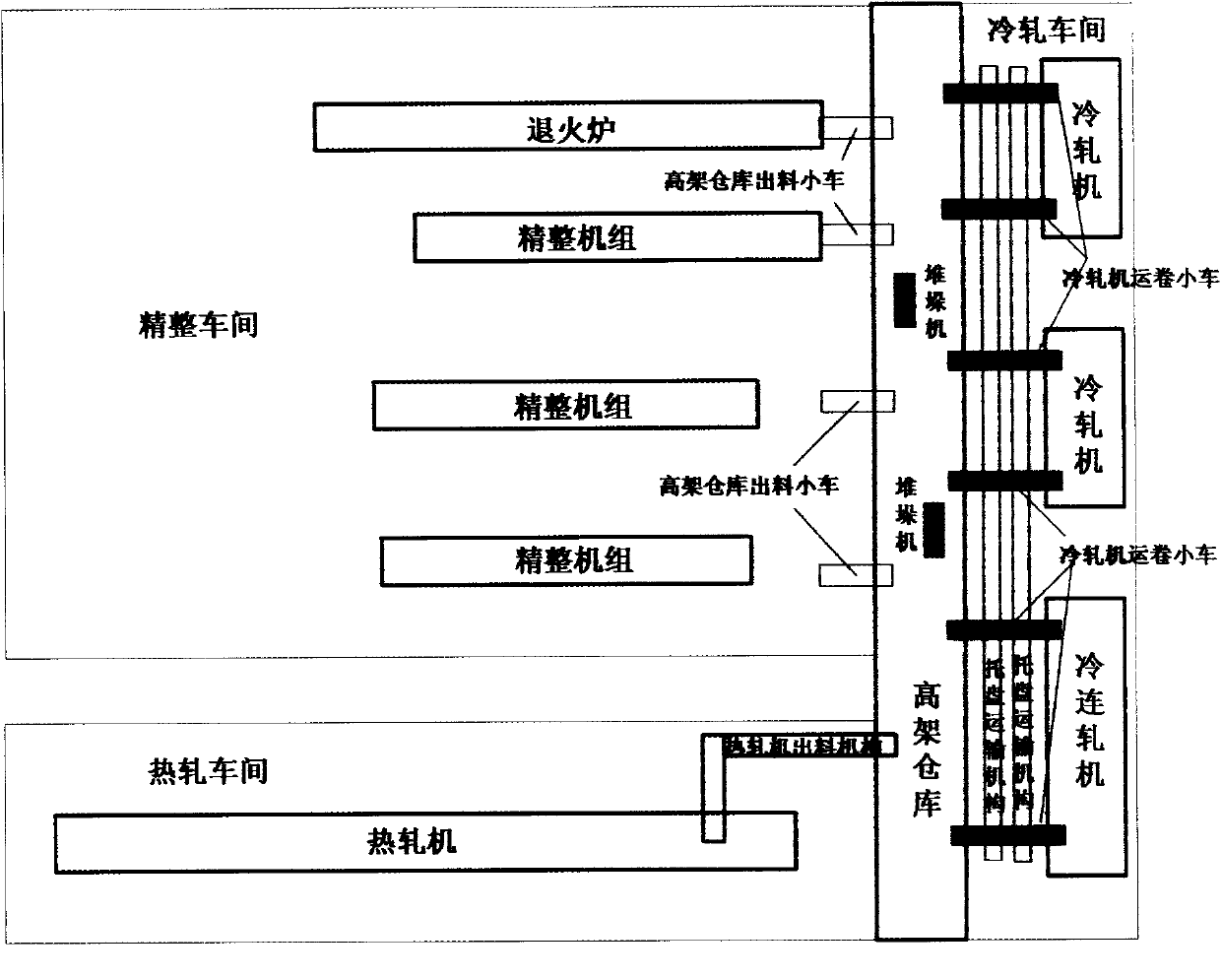

[0016] figure 1 It is only a schematic diagram of one of the configuration methods of the present invention. In order to clearly illustrate the positional configuration relationship between the aluminum strip production equipment, figure 1 Directly use text to describe the mutual position of each device. According to the technical scheme of the present invention, there are many types of process configuration schemes. For example, the hot rolling workshop is arranged above the finishing workshop (relatively figure 1 The hot rolling workshop is located below the finishing workshop). Regardless of the process configuration scheme, it must conform to the process configuration method of the present invention.

[0017] figure 1 Only the configuration relationships of the production workshops related to the high-bay warehouse are given. The relevant production workshops include: hot rolling workshop, cold rolling workshop and finishing workshop. The hot rolling workshop includes hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com