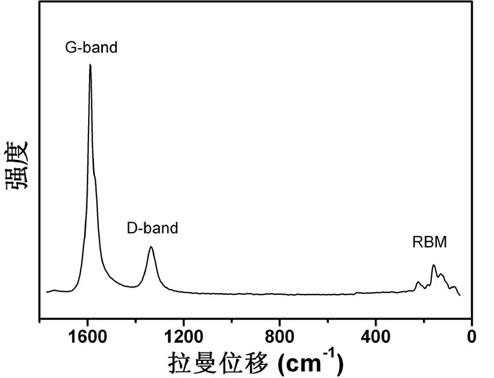

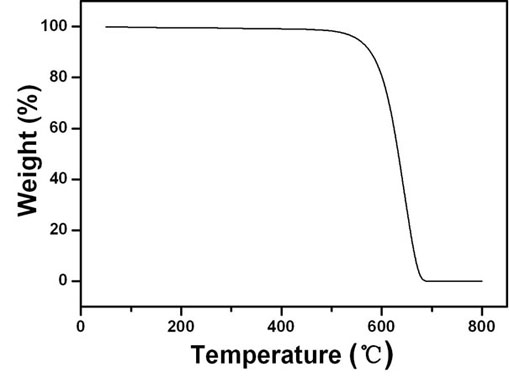

Method for preparing vertical array of high-purity single-walled carbon nanotubes

A single-walled carbon nanotube and vertical arrangement technology is applied in the field of preparing high-purity single-walled carbon nanotube vertical arrays, which can solve the problems of difficult single-walled carbon nanotube arrays and low purity of carbon nanotubes, and achieves high purity, The effect of high growth efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

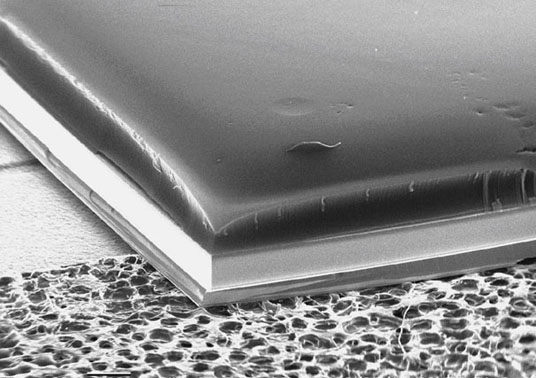

[0033] 1. Fabrication of vertical arrays of single-walled carbon nanotubes

[0034] (1) Cleaning of the substrate: select (100) monocrystalline silicon wafer as the growth substrate, cut it into small pieces with a size of 1×1cm, and ultrasonically clean them in acetone, alcohol, and ultrapure water for 5 minutes; Finally, the substrate was blown dry with high-purity nitrogen.

[0035] (2) Put the substrate into the vacuum chamber of the electron beam evaporation equipment and pump it to 1×10 -4 After Pa, first deposit 30nm of Al 2 o 3 thin film, and then deposit a 1.5nm Fe thin film under the condition of not breaking the vacuum; take out the sample after the coating is finished, and use it as a catalyst for the growth of carbon nanotubes.

[0036] (3) Put the substrate with the catalyst into the quartz tube of the chemical vapor deposition system, seal it and let 2000 sccm of helium and hydrogen (He / H 2 =4 / 1), and set the program to heat up to 850°C at a rate of 50°C / min...

Embodiment 2

[0050] 1. Fabrication of vertical arrays of single-walled carbon nanotubes

[0051] (1) Cleaning of the substrate: select (100) monocrystalline silicon wafer as the growth substrate, cut it into small pieces with a size of 1×1cm, and ultrasonically clean them in acetone, alcohol, and ultrapure water for 5 minutes; Finally, the substrate was blown dry with high-purity nitrogen.

[0052] (2) Put the substrate into the vacuum chamber of the magnetron sputtering equipment and pump it to 2×10 -4 After Pa, first deposit 30nm of Al 2 o 3 film, and then deposit a 1.2nm Fe film under the condition of not breaking the vacuum; take out the sample after the coating is finished, and use it as a catalyst for the growth of carbon nanotubes.

[0053] (3) Put the substrate with the catalyst into the quartz tube of the chemical vapor deposition system, seal it and let 2000 sccm of helium and hydrogen (He / H 2 =4 / 1), and set the program to heat up to 850°C at a rate of 50°C / min.

[0054] (4)...

Embodiment 3

[0059] Example 3 Preparation of vertical array of single-walled carbon nanotubes

[0060] (1) Cleaning of the substrate: select (100) monocrystalline silicon wafer as the growth substrate, cut it into small pieces of 1cm×1cm, and ultrasonically clean them in acetone, alcohol, and ultrapure water for 5 minutes; finally , and dry the substrate with high-purity nitrogen.

[0061] (2) Put the substrate into the vacuum chamber of the electron beam evaporation equipment and pump it to 1×10 -4 After Pa, first deposit 10nm of Al 2 o 3 thin film, and then deposit a 1.0nm Fe thin film under the condition of not breaking the vacuum; take out the sample after the coating is finished, and use it as a catalyst for the growth of carbon nanotubes.

[0062] (3) Put the substrate with the catalyst into the quartz tube of the chemical vapor deposition system, seal it and pass in 2000 sccm of argon and hydrogen (Ar / H 2 =6 / 4), and set the program to heat up to 850°C at a rate of 50°C / min.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average height | aaaaa | aaaaa |

| Average height | aaaaa | aaaaa |

| Average height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com