Asphalt emulsifier for anionic emulsified asphalt cement plaster

An asphalt emulsifier and emulsified asphalt technology, which is applied in the field of asphalt emulsifier for anionic emulsified asphalt cement mortar, can solve the problems such as difficulty in maintaining the stability of the air content of the mortar and the shape of the bubbles, fast demulsification of the emulsified asphalt, and short working time of the mortar. Achieve the effect of small particle size, strong emulsifying ability and moderate foaming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

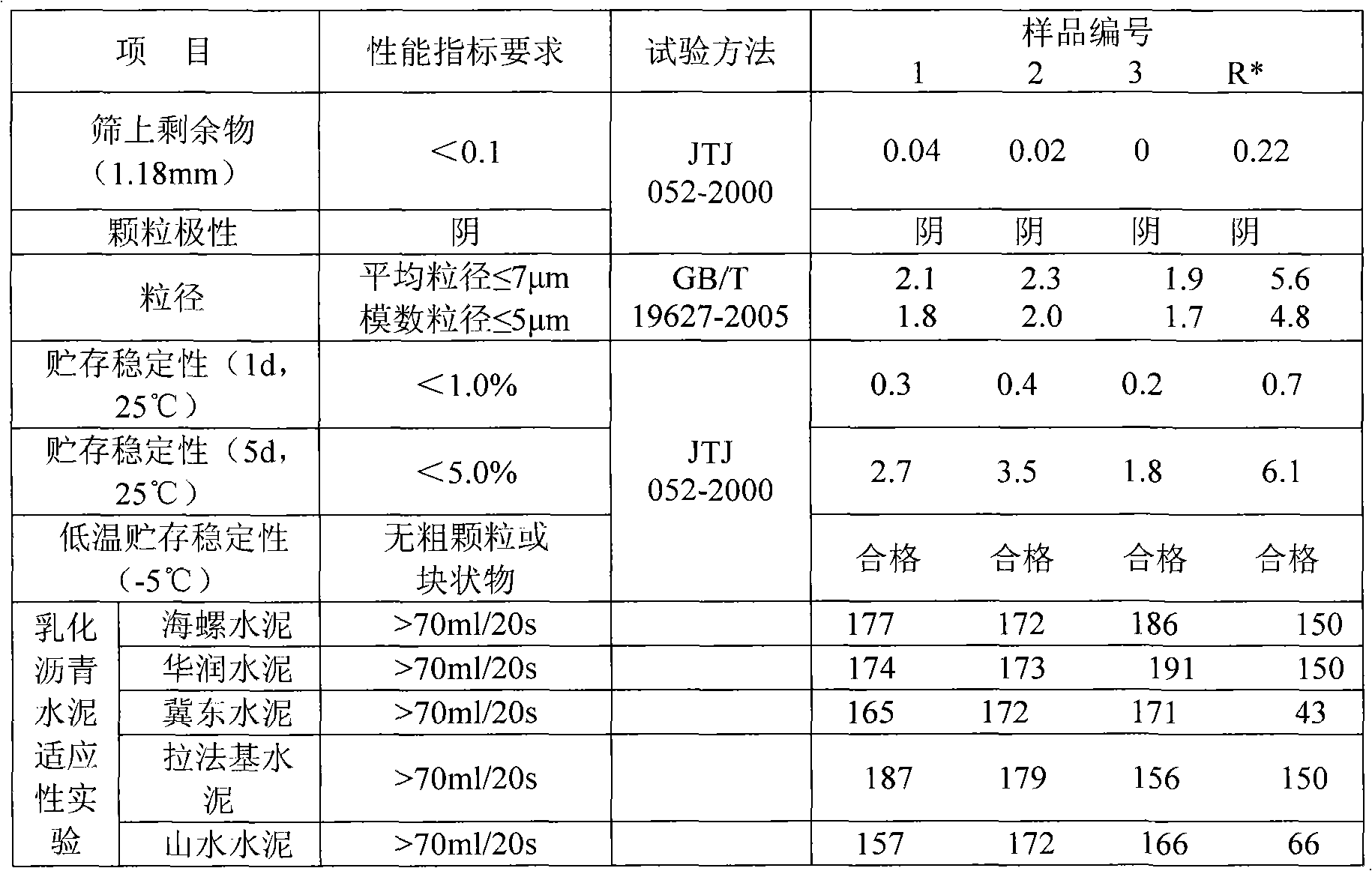

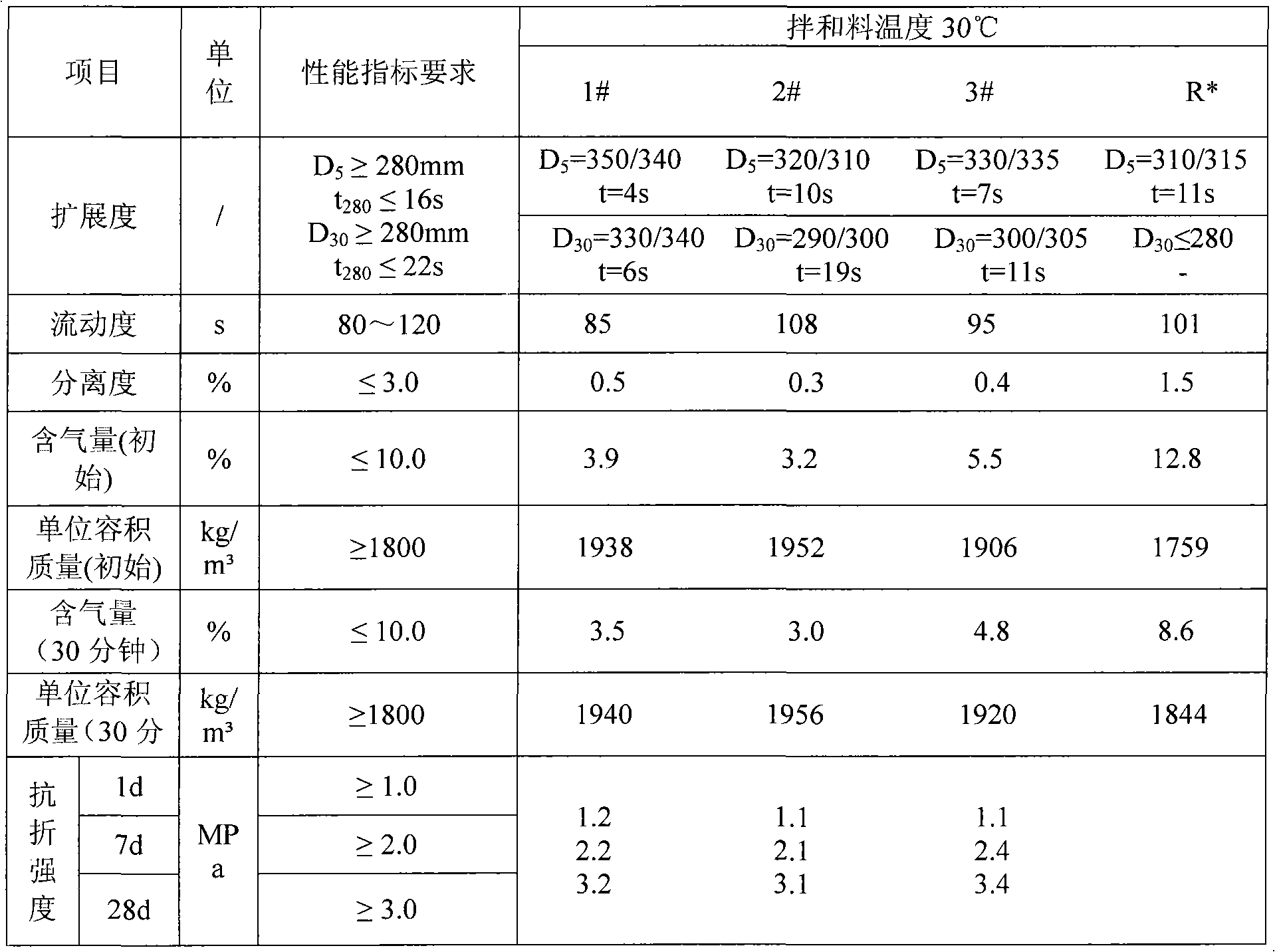

Embodiment 1

[0017] Take 25 grams of sodium lignosulfonate (sodium broadleaf pine lignosulfonate, molecular weight about 22000, Vanisperse CB from Borregaard) and 25 grams of octylphenol polyether (number average molecular weight 2500), 2 grams of NaOH and carboxymethyl fiber 0.15 grams of sodium carboxymethyl (the number average molecular weight of sodium carboxymethyl cellulose is 15000), dissolved in 20 grams of water and stirred uniformly, the obtained sample is numbered 1 and tested for emulsified asphalt.

Embodiment 2

[0019] Take sodium lignosulfonate (degree of sulfonation 8.7%, molecular weight 35000, sodium pine lignosulfonate (from LFCA8101 of Shanghai Longfu Industrial Company)) and fatty alcohol ether (the carbon number on the aliphatic group is C 12 -C 18 , The number average molecular weight is 1020, 30 grams each of O-20 from Xingtai Auxiliary Factory, 2 grams of NaOH and 0.2 grams of sodium carbonate, dissolved in 22 grams of water and dispersed uniformly, the resulting sample is numbered 2 and used Emulsified asphalt test.

Embodiment 3

[0021] Take 25 grams of sodium lignosulfonate (degree of sulfonation 8.7%, molecular weight 35000, sodium conifer lignosulfonate (from LFCA8101 of Shanghai Longfu Industrial Company)), fatty alcohol ether (carbon on aliphatic group) Number is C 12 -C 18 , Number average molecular weight 1020, 12 grams of O-20 from Xingtai Auxiliary Factory, 22 grams of secondary octylphenol polyoxyethylene ether (number average molecular weight 1530), 1.5 grams of NaOH and 0.1 grams of sodium borate, dissolved in 13 Gram of water and stir evenly. The resulting sample is numbered 3 and used for emulsified asphalt test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com