A kind of preparation method of three-dimensional network ammonium vanadate nanocrystal

A nanocrystal and three-dimensional network technology, which is applied in the field of preparation of three-dimensional network ammonium vanadate nanocrystals, to achieve the effect of good dispersion and easy control of shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of three-dimensional network ammonium vanadate nanocrystals, the specific process is:

[0032] Step 1, the NH 4 VO 3 Uniformly dissolved in 100% ethylene glycol solvent and heated to 30°C to obtain NH at a concentration of 0.05mol / L 4 VO 3 solution;

[0033] Step 2, use 0.1mol / L HCl solution to NH 4 VO 3 The pH of the solution was adjusted to 3, and then reacted for 2 hours under a 300W ultrasonic environment to obtain a solution;

[0034] Step 3, the A solution is placed in a polytetrachlorethylene-lined reactor, the filling ratio in the reactor is 50%, and the reactor is set in a homogeneous hydrothermal reaction, and reacted at 180 ° C for 6 hours, Suspension is obtained in the reactor;

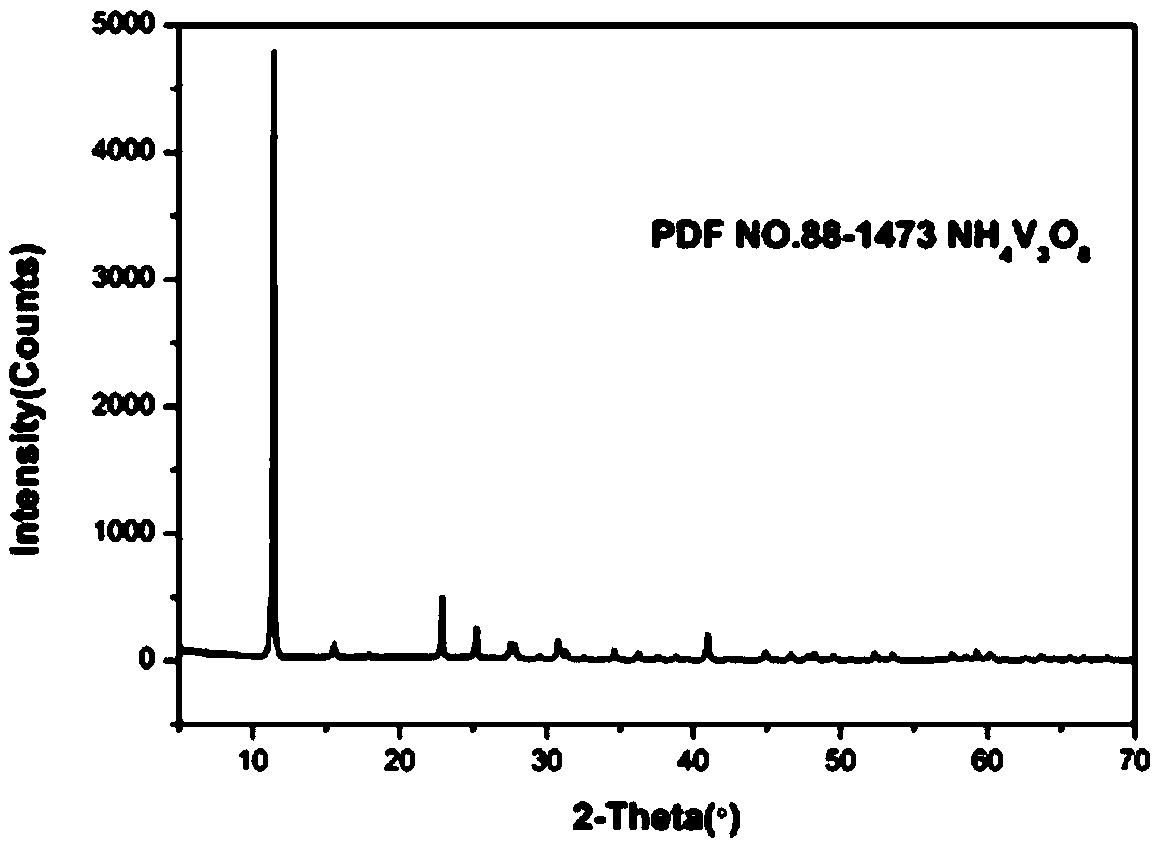

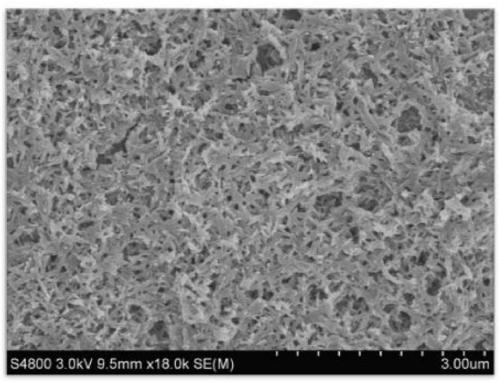

[0035] Step 4: centrifuge the suspension to obtain a powder product, wash the powder product alternately with deionized water and absolute ethanol, and then dry the cleaned product in an electric vacuum drying oven for 8 hours to obtain a three-dimensional netwo...

Embodiment 2

[0037] Preparation of three-dimensional network ammonium vanadate nanocrystals, the specific process is:

[0038] Step 1, the NH 4 VO 3 Uniformly dissolved in 100% ethylene glycol solvent and heated to 50°C to obtain NH with a concentration of 0.03mol / L 4 VO 3 solution;

[0039] Step 2, use 0.1mol / L HCl solution to NH 4 VO 3 The pH of the solution was adjusted to 3, and then reacted for 1 hour under a 300W ultrasonic environment to obtain A solution;

[0040] Step 3, place A solution in a polytetrachlorethylene-lined reactor, the filling ratio in the reactor is 60%, and set the reactor in a homogeneous hydrothermal reaction, and react at 160°C for 8 hours, Suspension is obtained in the reactor;

[0041] Step 4: centrifuge the suspension to obtain a powder product, wash the powder product alternately with deionized water and absolute ethanol, and then dry the cleaned product in an electric vacuum drying oven for 8 hours to obtain a three-dimensional network NH 4 V 3 o ...

Embodiment 3

[0043] Preparation of three-dimensional network ammonium vanadate nanocrystals, the specific process is:

[0044] Step 1, the NH 4 VO 3 Uniformly dissolved in 100% ethylene glycol solvent and heated to 35°C to obtain NH with a concentration of 0.08mol / L 4 VO 3 solution;

[0045] Step 2, use 0.2mol / L HCl solution to NH 4 VO 3 The pH of the solution was adjusted to 1, and then reacted for 2 hours under a 200W ultrasonic environment to obtain a solution;

[0046] Step 3, the A solution is placed in a polytetrachlorethylene-lined reactor, the filling ratio in the reactor is 40%, and the reactor is set in a homogeneous hydrothermal reaction, and reacted at 170 ° C for 7 hours, Suspension is obtained in the reactor;

[0047] Step 4: Centrifuge the suspension to obtain a powder product, wash the powder product alternately with deionized water and absolute ethanol, and then dry the cleaned product in an electric vacuum drying oven for 5 hours to obtain a three-dimensional net...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com