Variable stiffness spring for realizing conversion of work rings and support rings

A technology of variable stiffness springs and working rings, applied in the field of variable stiffness springs, can solve the problems of small change in spring stiffness, poor compactness, and small stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings of the description.

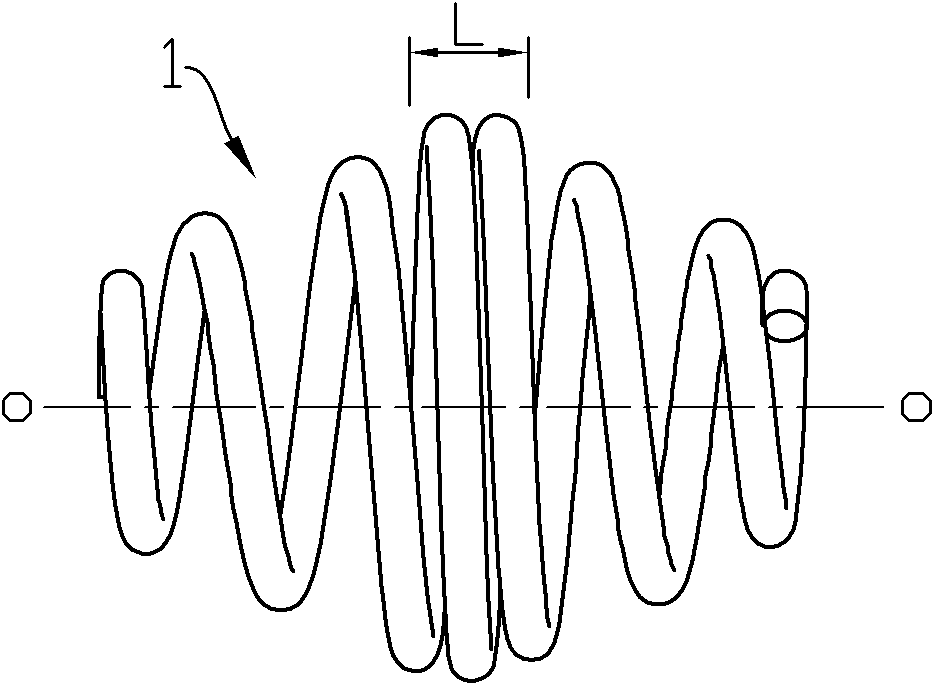

[0025] The variable stiffness spring 1 that realizes the conversion of the working ring and the supporting ring of the present invention, such as Figure 1-4 As shown, it is made of spring steel wire in a helical shape, and the characteristic is that the stiffness of the working ring L in the middle part in the axial direction o-o of the spring is smaller than that of the rest of the working ring, so that the middle part of the spring is under a certain pressure at both ends of the spring. The axial contact of the working ring becomes the supporting ring and divides the spring into two sections.

[0026] According to the spring stiffness formula:

[0027] F ′ = F f = Gd 4 8 D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com