Injection molding method for in-mold ornament

A technology of injection molding and film interior decoration, applied in the direction of coating, etc., can solve the problems of single pattern, poor fluidity of rubber material, difficulty in forming, lack of three-dimensional effect and layering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

[0022] A method for injection molding of film interior decoration, which comprises the steps of:

[0023] A), one-time molding stage, using IMR technology to form injection molded parts with decorative patterns:

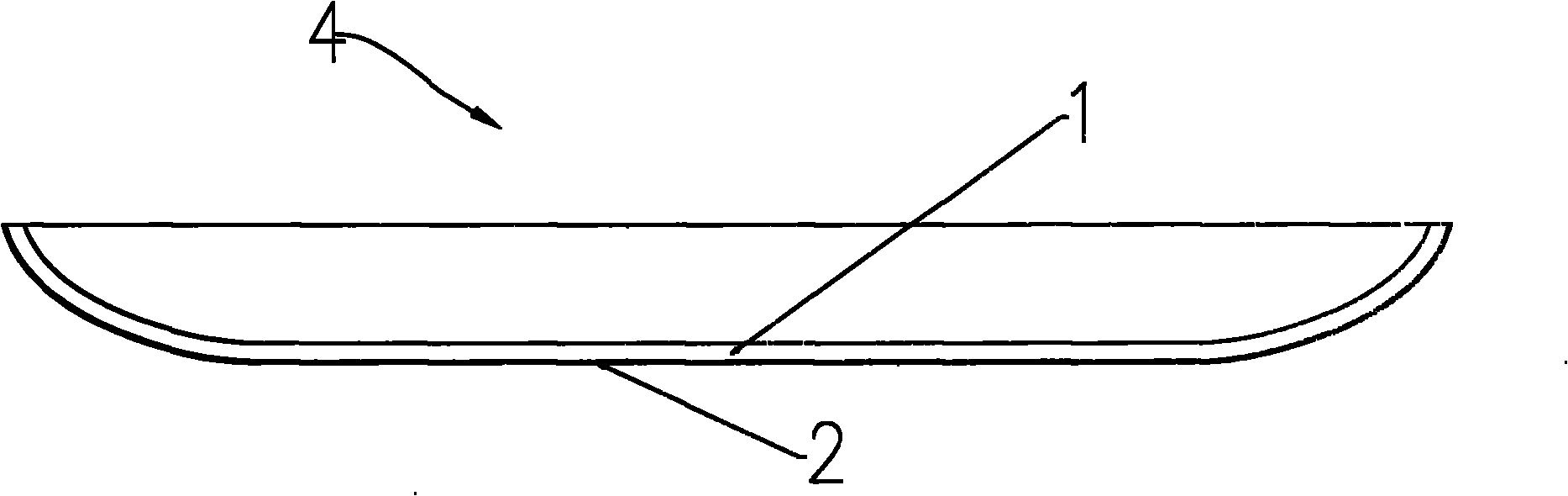

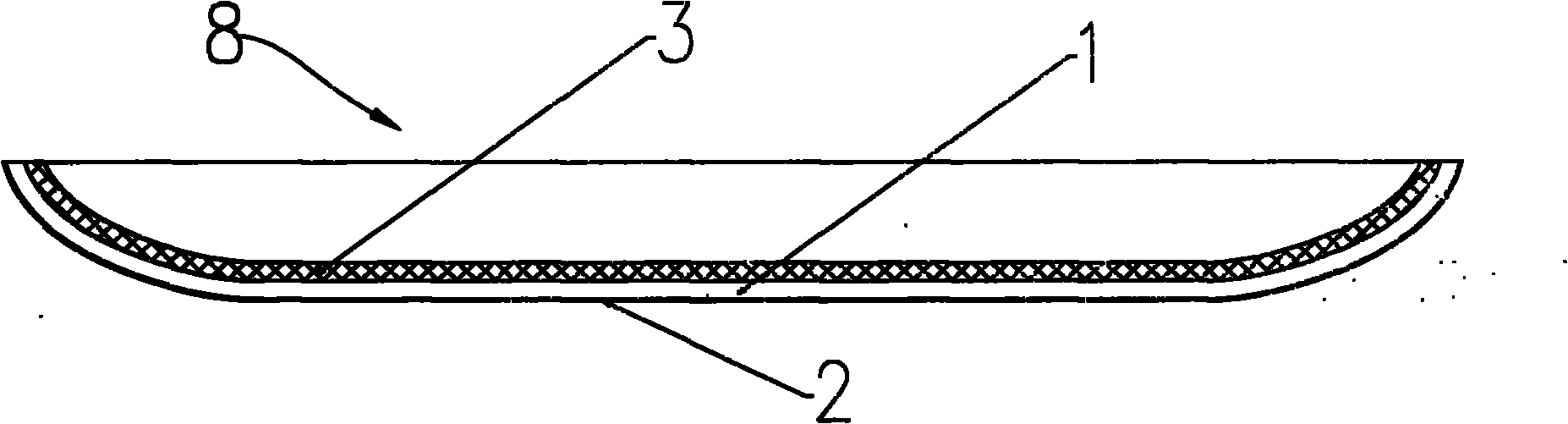

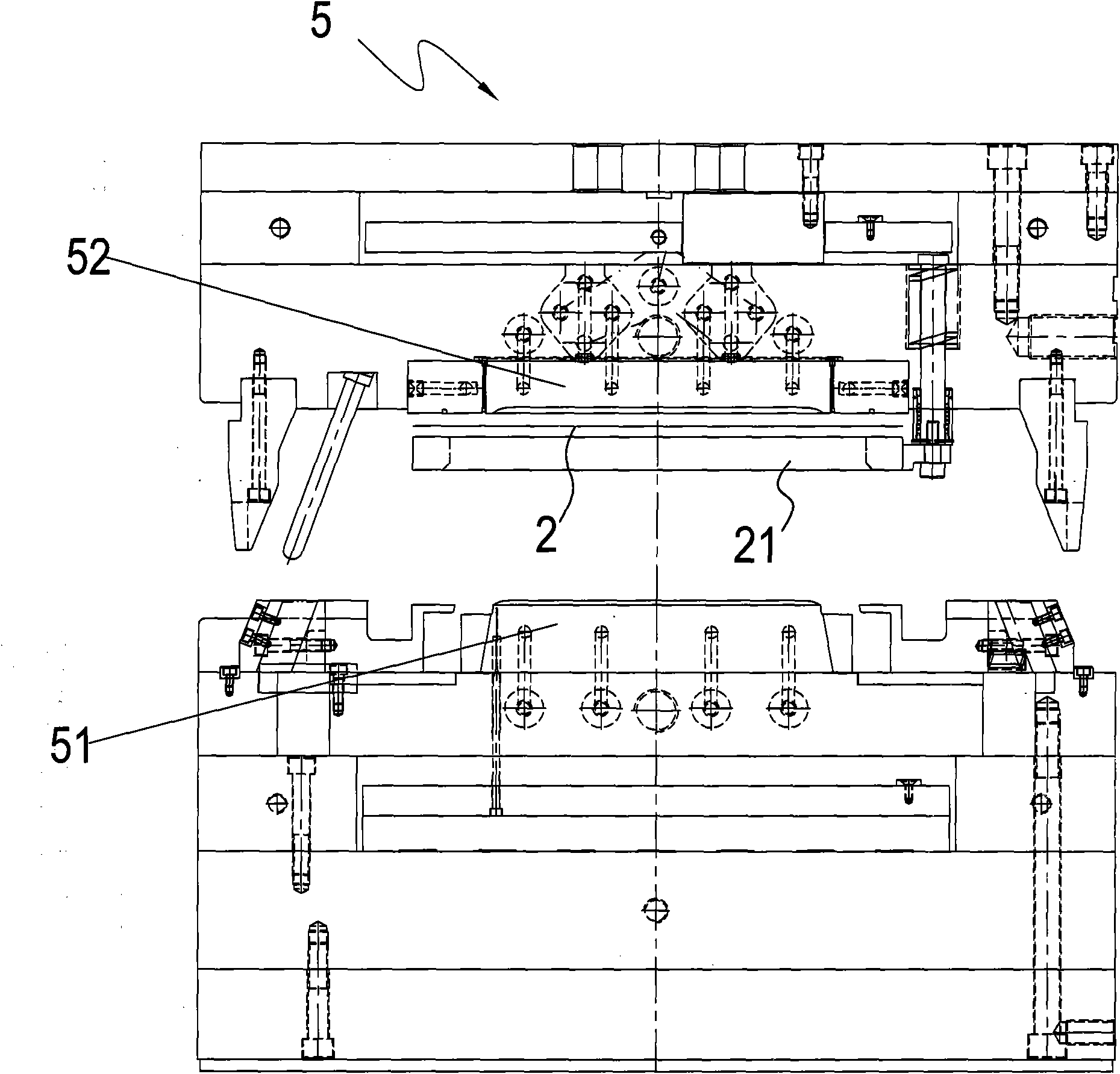

[0024] S1), with the film 2 that is printed with pattern layer, the material of this film is PET, PC etc., as attached image 3 As shown, the above-mentioned film 2 is loaded between the first male mold 51 and the first female mold 52 of the first forming mold 5, covering the surface of the first female mold 52;

[0025] S2), pressing the film 2 through the film pressing frame 21, making it stick on the surface of the first master mold 52;

[0026] S3), vacuumize the mold cavity of the first forming mold 5, so that the film 2 is stuck in the mold cavity;

[0027] S4), close the mold, and inject the product with transparent injection molding mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com