Shell assembly, preparation method thereof and electronic equipment

A technology of shell assembly and texture layer, applied in the field of shell assembly and its preparation, can solve the problems of complex LOGO process of shell, lack of layering, single shell texture effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

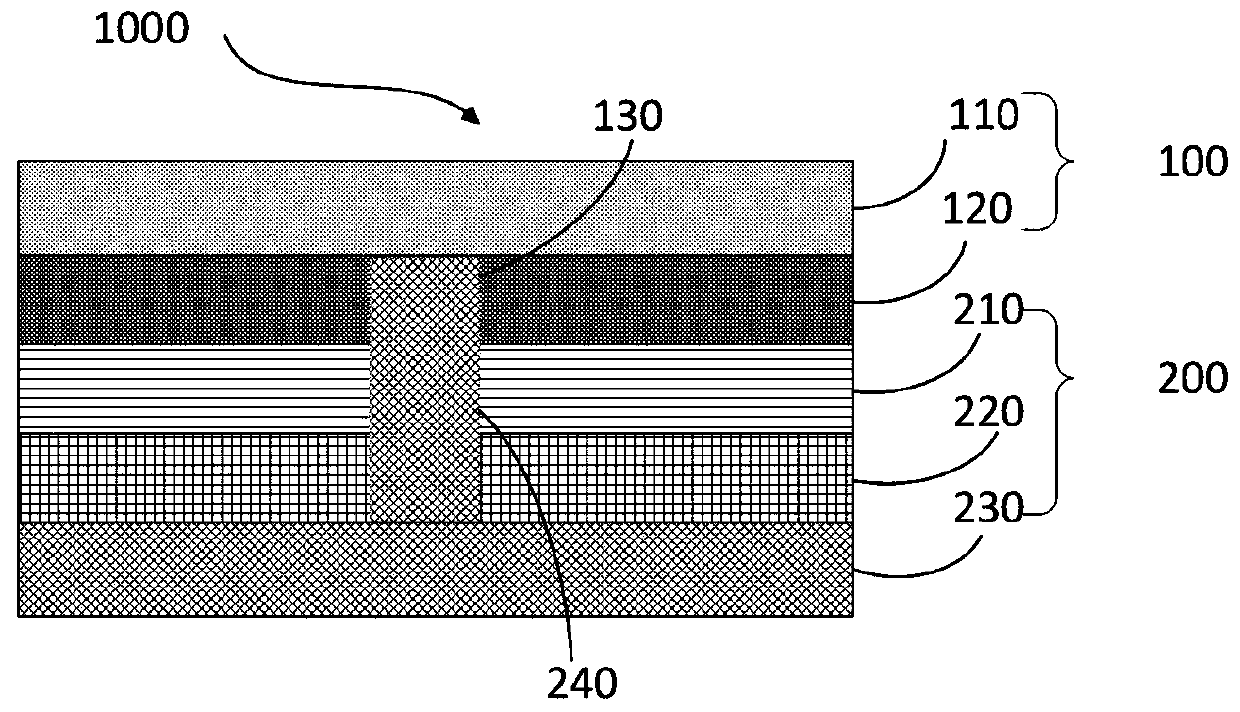

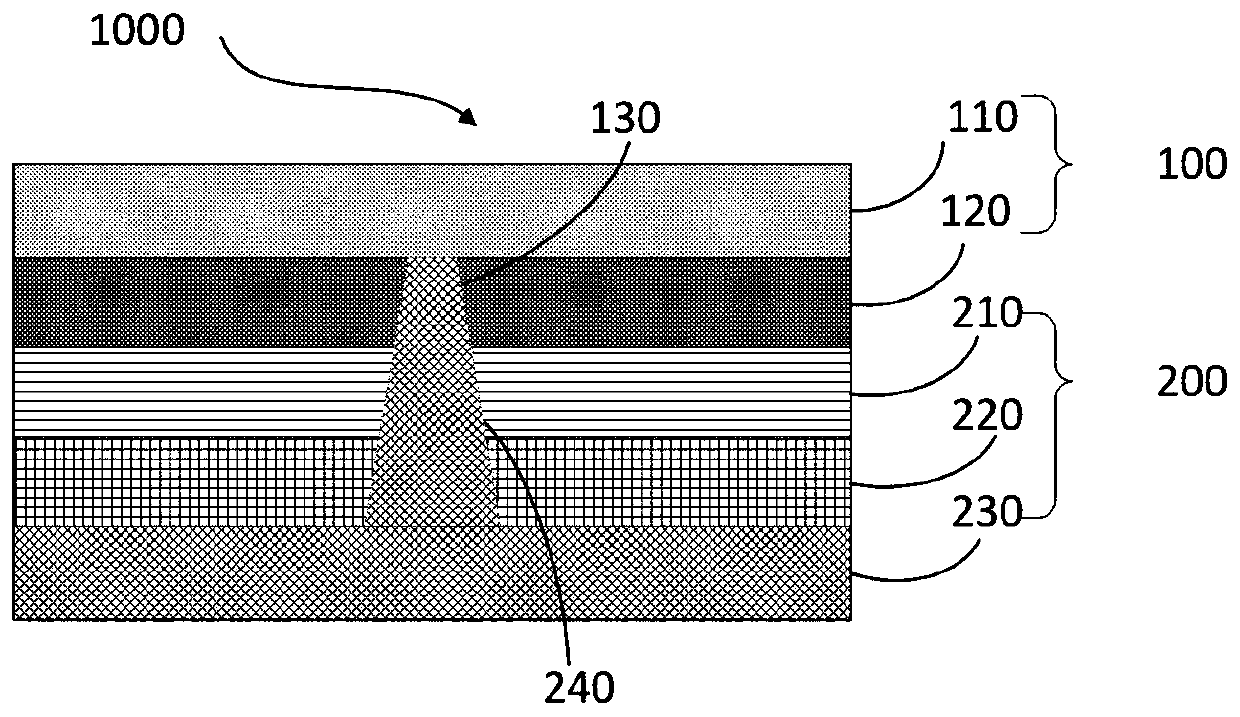

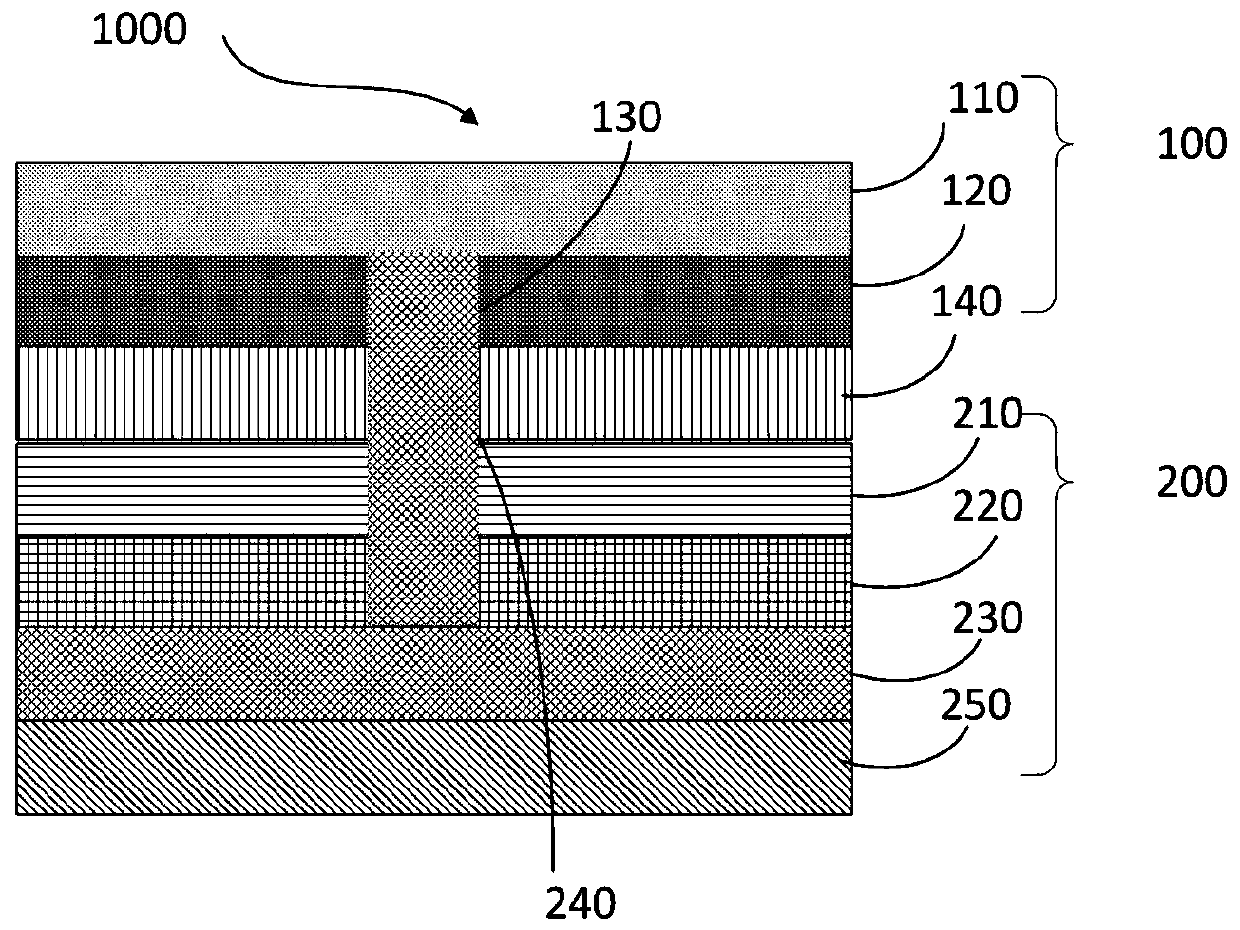

[0069] (1) UV transfer is carried out on the first substrate layer formed by laminating polycarbonate and polymethyl methacrylate (the thickness of polycarbonate is 0.59mm, and the thickness of polymethyl methacrylate is 0.05mm) to form the first texture layer, the thickness of the first texture layer is 8 μm;

[0070] (2) On the side of the first texture layer away from the first substrate layer, a first coating layer is formed with a thickness of 35 nm.

[0071] (3) A color layer is formed on one side of the second backing layer, the second backing layer composition is a PC material, the color layer is formed by printing ink, and the printing ink is a UV curing type, and the thickness of each layer of monochrome ink is 1.5um, the color effect of the pattern is formed by combining CMYK four-color inks, the total thickness is 6μm

[0072] (4) Attach the second substrate layer to the first texture layer, and use OCA glue for bonding.

[0073] (5) Form a second hollow area on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com