Steel bar arrangement method and steel bar arrangement device for reinforced concrete deep beam

A reinforced concrete and concrete technology, applied in the direction of joists, girders, trusses, etc., can solve the problems of weakened bonding performance between concrete and steel plates, complicated production methods, and falling off of the concrete protective layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

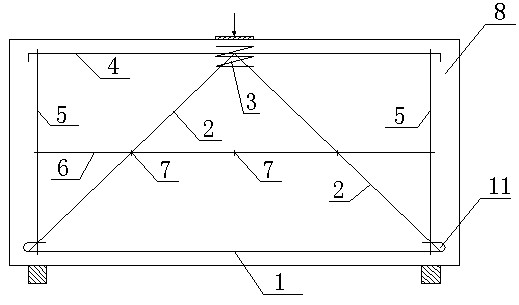

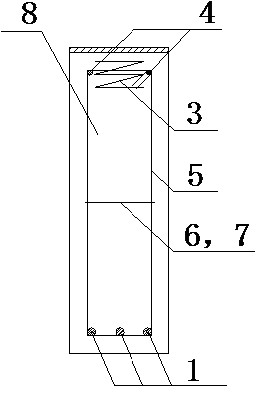

[0028] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a reinforcement method for reinforced concrete deep beams comprises the following steps:

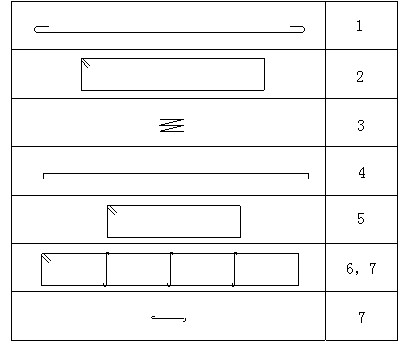

[0030] The first step: horizontally arrange the longitudinal tension reinforcement 1 at the bottom of the deep beam; the ends of the longitudinal tension reinforcement 1 are respectively provided with hooks 11

[0031] Step 2: One end of the two groups of obliquely compressed steel bars 2 is respectively fixed in the hooks at both ends of the obliquely compressed steel bar 1 on the same side, and the other end is overlapped with each other at the top of the deep beam. The tension bars 1 form a triangular arrangement, and the top is covered by the spiral bars 3 at the overlapping position;

[0032] Step 3: After passing through the spiral bar 3, the top distribution reinforcement 4 is lap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com