Heat-storage type vacuum heat collector tube

A vacuum heat collector tube and heat storage technology, applied in the field of solar thermal utilization, can solve the problems of destroying the aesthetic appearance of buildings, urban landscape pollution, and occupying more space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

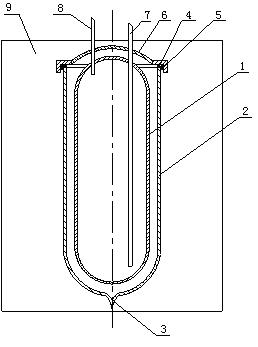

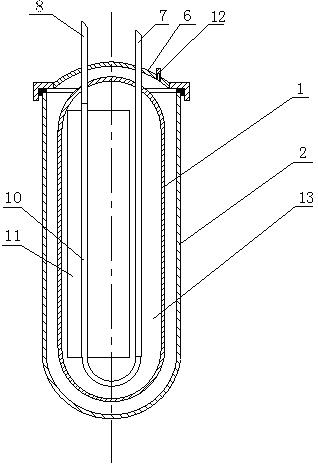

[0018] Such as figure 1 As shown, the present invention is provided with a metal heat storage tube 1 with a solar heat absorption coating on the outer surface, and the inner surface of the metal heat storage tube 1 can be provided with an anticorrosive coating.

[0019] A transparent glass tube 2 is arranged outside the metal heat storage cylinder 1, and the lower end of the glass tube 2 is a blind end, and a glass exhaust nozzle 3 is arranged. The upper end of the glass tube 2 is welded to one end of the expansion alloy ring 5 with glass solder 4, and the other end of the expansion alloy ring 5 is hermetically connected with an arched metal cover 6.

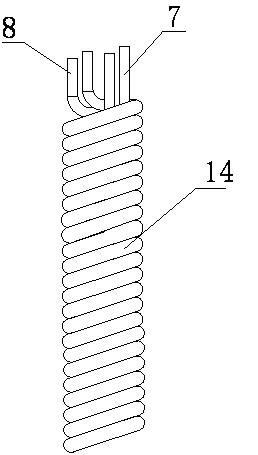

[0020] At least one liquid inlet pipe 7 and at least one liquid outlet pipe 8 are arranged on the metal cover 6 in a sealed connection. The lower end of the liquid inlet pipe 7 extends into the inner bottom of the metal heat storage cylinder 1, and the lower end of the liquid outlet pipe 8 is connected to The upper end of the metal h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com